Are you gearing up for a career in Hammer Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hammer Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

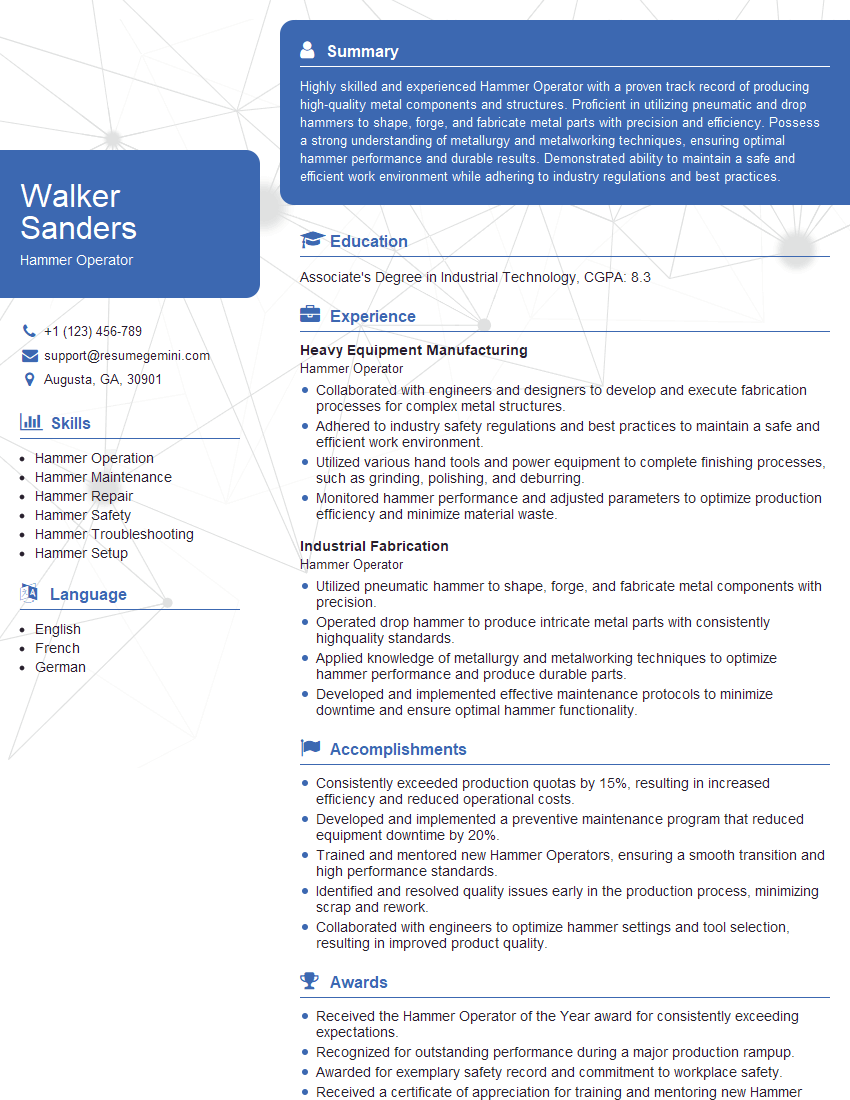

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hammer Operator

1. What are the different types of hammers used in construction?

As a Hammer Operator, I have extensive experience utilizing a wide range of hammers in construction. These include:

- Claw Hammer: Primarily used for driving nails, removing them, and basic demolition tasks.

- Framing Hammer: Heavier and designed for framing houses and other large-scale construction projects.

- Sledgehammer: Intended for breaking concrete and other heavy-duty applications.

- Mallet: Used to pound materials without damaging their surface, such as when assembling furniture.

- Jackhammer: A power tool that delivers rapid, high-impact blows for breaking up hard materials like concrete and asphalt.

2. How do you select the right hammer for a specific task?

Factors considered when selecting the appropriate hammer:

- Type of material being worked on

- Size and weight of the hammer

- Force or impact required

Specific examples of hammer selection:

- For driving nails into wood, a claw hammer or framing hammer would be suitable.

- For breaking up concrete, a sledgehammer or jackhammer would be necessary.

- For assembling furniture, a mallet would be used to avoid damage to the materials.

3. What safety precautions should be taken when using hammers?

To ensure safety when using hammers, I strictly adhere to the following precautions:

- Always wear safety glasses to protect against flying debris.

- Inspect hammers regularly for damage or loose parts.

- Hold the hammer securely and use proper striking techniques to avoid injuries.

- Be aware of surroundings and potential hazards, such as overhead wires or slippery surfaces.

- Wear appropriate clothing, including gloves and sturdy footwear, to minimize the risk of injuries.

4. How do you maintain and care for hammers?

To ensure optimal performance and longevity of hammers, I follow a comprehensive maintenance routine:

- After each use, I clean the hammer head and handle to remove dirt and debris.

- I regularly inspect the hammer for signs of wear or damage, such as loose bolts or cracks.

- If any damage is found, I repair or replace the hammer to avoid accidents.

- I store hammers in a dry and secure location to prevent rust and damage.

- I follow the manufacturer’s instructions for any specific maintenance requirements.

5. What techniques do you use to strike effectively with a hammer?

For effective and precise striking, I employ the following techniques:

- Gripping the hammer firmly with one hand near the end of the handle.

- Keeping my wrist straight and my elbow slightly bent.

- Swinging the hammer in a controlled arc with my arm and shoulder.

- Focusing on striking the target accurately and with the appropriate force.

- Adjusting the angle of the hammer if necessary to achieve optimal results.

6. How do you handle different types of materials when using a hammer?

To handle different materials effectively when using a hammer, I tailor my approach as follows:

- For hard materials like concrete or metal, I use a hammer with a heavier head and strike with more force.

- For softer materials like wood or plastic, I use a lighter hammer and strike with less force to avoid damage.

- I also adjust the angle of the hammer’s head depending on the material and the desired outcome.

7. What factors influence the choice of hammer weight?

When selecting the appropriate hammer weight, I consider several factors:

- The type of material being worked on (harder materials require heavier hammers).

- The size and thickness of the material (larger materials require heavier hammers).

- The desired impact force (more force requires heavier hammers).

- My own strength and comfort level (lighter hammers are easier to handle for extended periods).

8. How do you determine the correct striking point on a hammer?

To determine the correct striking point on a hammer, I follow these guidelines:

- For a standard hammer, the striking point is typically located in the center of the head.

- For hammers with a claw or other special features, the striking point may be offset slightly.

- I ensure that the striking point is clean and free of any defects or damage.

9. Describe the proper grip for using a hammer safely and efficiently.

To ensure safety and efficiency when using a hammer, I maintain the following proper grip:

- I grasp the handle firmly near the end, with my thumb resting on top.

- My grip is relaxed but secure, allowing me to control the hammer’s movements.

- I keep my wrist straight and my elbow slightly bent.

10. Explain the importance of using the right hammer for the job.

Using the right hammer for the job is essential for several reasons:

- Safety: Using an inappropriate hammer can increase the risk of accidents and injuries.

- Efficiency: The correct hammer will allow you to complete the task more quickly and effectively.

- Accuracy: The right hammer will provide the necessary precision for the job.

- Material preservation: Using the wrong hammer can damage the material you are working on.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hammer Operators are responsible for operating and maintaining large, high-powered hammers used in industrial settings. Their primary tasks include:

1. Hammer Operation

Operate hydraulic or pneumatic hammers to crush, break, or shape materials such as rocks, concrete, and metal.

- Position the hammer accurately and adjust settings for optimal performance.

- Monitor the hammer’s operation and make adjustments as needed to ensure efficiency.

2. Material Handling

Load and unload materials to and from the hammer for processing.

- Use hoists, forklifts, or other equipment to move heavy materials.

- Ensure that materials are properly loaded and secured before operating the hammer.

3. Machine Maintenance

Perform routine maintenance on the hammer, including lubrication, cleaning, and minor repairs.

- Inspect the hammer regularly for any signs of wear or damage.

- Replace worn or damaged parts as necessary.

4. Safety

Follow all safety protocols and procedures related to hammer operation and material handling.

- Wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and gloves.

- Operate the hammer in a controlled environment and maintain a safe work area.

Interview Tips

Preparing thoroughly for your Hammer Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and position

Research the company’s background, industry, and specific needs. Understand the role you are applying for and how your skills and experience align with the requirements.

2. Practice answering common interview questions

Anticipate potential interview questions and prepare thoughtful responses. Use the STAR method (Situation, Task, Action, Result) to highlight your relevant skills and experiences.

3. Highlight your mechanical aptitude and safety awareness

Emphasize your understanding of hammer operation principles, maintenance practices, and safety protocols. Share examples of your experience in handling heavy machinery.

4. Demonstrate your physical capabilities

Hammer Operators require a certain level of physical strength and endurance. Be prepared to describe your physical abilities and any relevant experience, such as lifting heavy objects or working in strenuous conditions.

5. Ask insightful questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your understanding of the role and the company’s objectives.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hammer Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hammer Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.