Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Keel Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

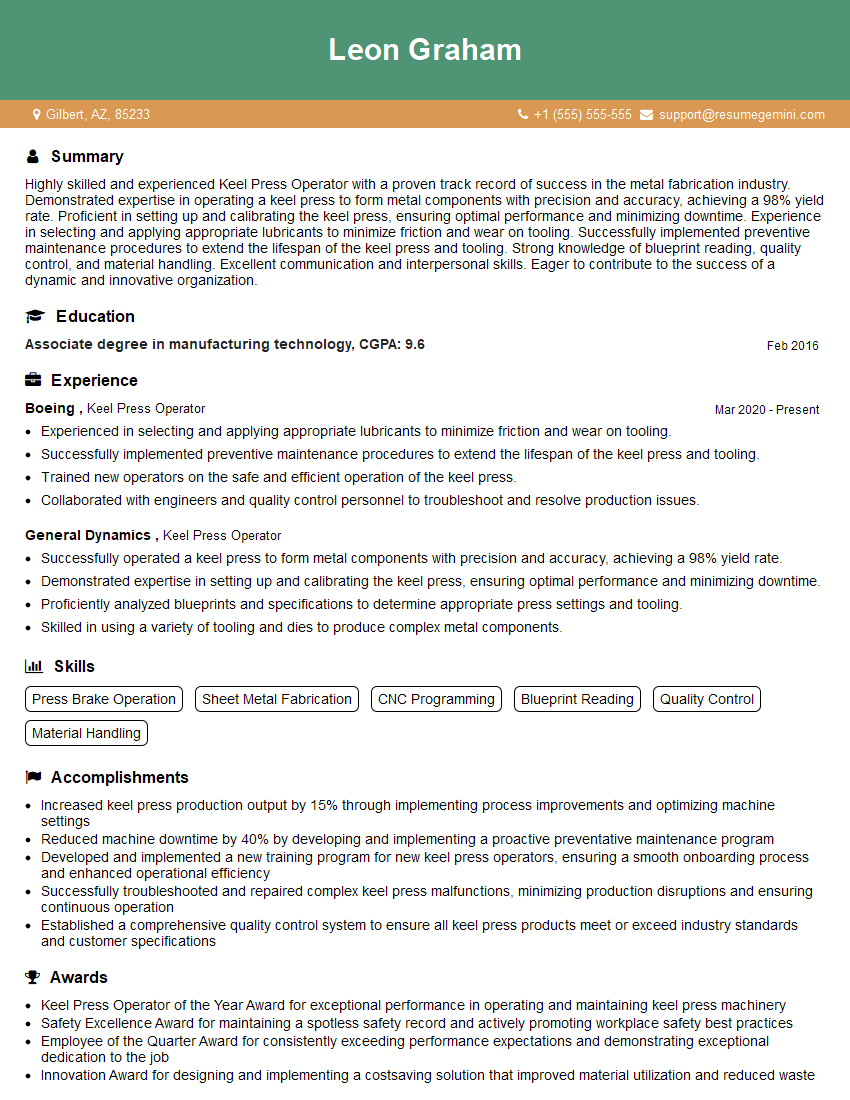

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Keel Press Operator

1. Describe the process of setting up a keel press for a new job.

- Review the job specifications and material properties.

- Select the appropriate die and tooling.

- Install the die and tooling in the press.

- Adjust the press settings, such as pressure, stroke, and speed.

- Run test pieces to verify the setup and make any necessary adjustments.

2. What are the critical quality characteristics (CQC) for keel press operations?

Dimensional Accuracy

- Ensure that the pressed parts meet the specified dimensions.

- Monitor and adjust the press settings to maintain consistent dimensions.

Surface Finish

- Inspect the pressed parts for scratches, dents, or other surface defects.

- Adjust the press tooling or process parameters to achieve the desired surface finish.

3. How do you troubleshoot common keel press problems, such as part distortion or cracking?

- Identify the potential causes of the problem, such as incorrect press settings, tooling wear, or material issues.

- Analyze the data and make adjustments to the press settings, tooling, or process to resolve the problem.

- Monitor the press operation to ensure that the problem has been resolved.

4. How do you ensure the safety of yourself and others when operating a keel press?

- Follow all safety protocols and guidelines.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Inspect the press and tooling for any potential hazards.

- Operate the press only when authorized and under controlled conditions.

5. How do you maintain and calibrate a keel press?

- Regularly clean and lubricate the press and its components.

- Inspect the press for any wear or damage.

- Calibrate the press according to the manufacturer’s specifications.

- Keep detailed maintenance and calibration records.

6. What are the different types of keel press tooling and their applications?

- Progressive dies: Used for high-volume production of complex parts.

- Compound dies: Used for forming and blanking operations in one stroke.

- Transfer dies: Used for transferring material from one station to another during the forming process.

- Forming dies: Used for shaping and bending material.

7. How do you select the appropriate keel press for a specific job?

- Consider the part geometry, material properties, and production volume.

- Determine the required press tonnage, stroke length, and speed.

- Review the press specifications and capabilities.

- Consult with the press manufacturer or a qualified technician.

8. How do you optimize the keel press process to improve efficiency and part quality?

- Use proper tooling and press settings.

- Minimize setup time.

- Implement automated feeding and unloading systems.

- Monitor and control the press process.

9. What are the latest trends and advancements in keel press technology?

- Automated press systems: Reduced labor costs and improved efficiency.

- High-speed presses: Increased production rates.

- Advanced tooling: Improved part quality and reduced tooling costs.

- Process monitoring and control systems: Enhanced process optimization.

10. How do you keep up with the latest developments in the keel press industry?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Network with other professionals in the field.

- Take continuing education courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Keel Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Keel Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Keel Press Operator is responsible for a variety of tasks related to the operation of a keel press, including:1. Machine Setup and Operation

The Keel Press Operator will be responsible for setting up and operating the keel press, including ensuring that the press is properly calibrated and that all safety precautions are in place.

- Set up and operate the keel press to produce high-quality parts.

- Calibrate and maintain the press to ensure accuracy and efficiency.

- Monitor the press during operation and make adjustments as needed.

2. Material Handling

The Keel Press Operator will be responsible for handling and loading materials into the press, including ensuring that the materials are properly aligned and that the press is operating at the correct speed.

- Load and unload materials from the press.

- Ensure that materials are properly aligned and secured.

- Adjust press speed and pressure to optimize production.

3. Quality Control

The Keel Press Operator will be responsible for inspecting parts produced by the press, including ensuring that the parts meet the required specifications and that they are free of defects.

- Inspect parts produced by the press for quality.

- Identify and correct any defects.

- Maintain records of production and quality control.

4. Maintenance and Repair

The Keel Press Operator will be responsible for performing basic maintenance and repairs on the press, including ensuring that the press is clean and well-maintained and that any necessary repairs are made promptly.

- Perform basic maintenance and repairs on the press.

- Lubricate moving parts and clean the press regularly.

- Identify and troubleshoot any mechanical issues.

Interview Tips

To ace your interview for a Keel Press Operator position, you should:1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture, the role of the Keel Press Operator, and what the company is looking for in a candidate.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and identify the key skills and experience that the company is looking for.

- Research the industry and the specific role of a Keel Press Operator.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked in an interview for a Keel Press Operator position. Take some time to practice your answers to these questions so that you can deliver them confidently and clearly.

- Tell me about your experience operating a keel press.

- What are your strengths and weaknesses as a Keel Press Operator?

- Why are you interested in this position?

3. Prepare Questions for the Interviewer

Asking the interviewer questions is a great way to show your interest in the position and the company. Prepare a few questions that you can ask the interviewer about the company, the position, and the industry.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement in this position?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Arrive at the interview on time, or even a few minutes early.

- Bring a copy of your resume and any other relevant materials with you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Keel Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.