Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Heavy Forging Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

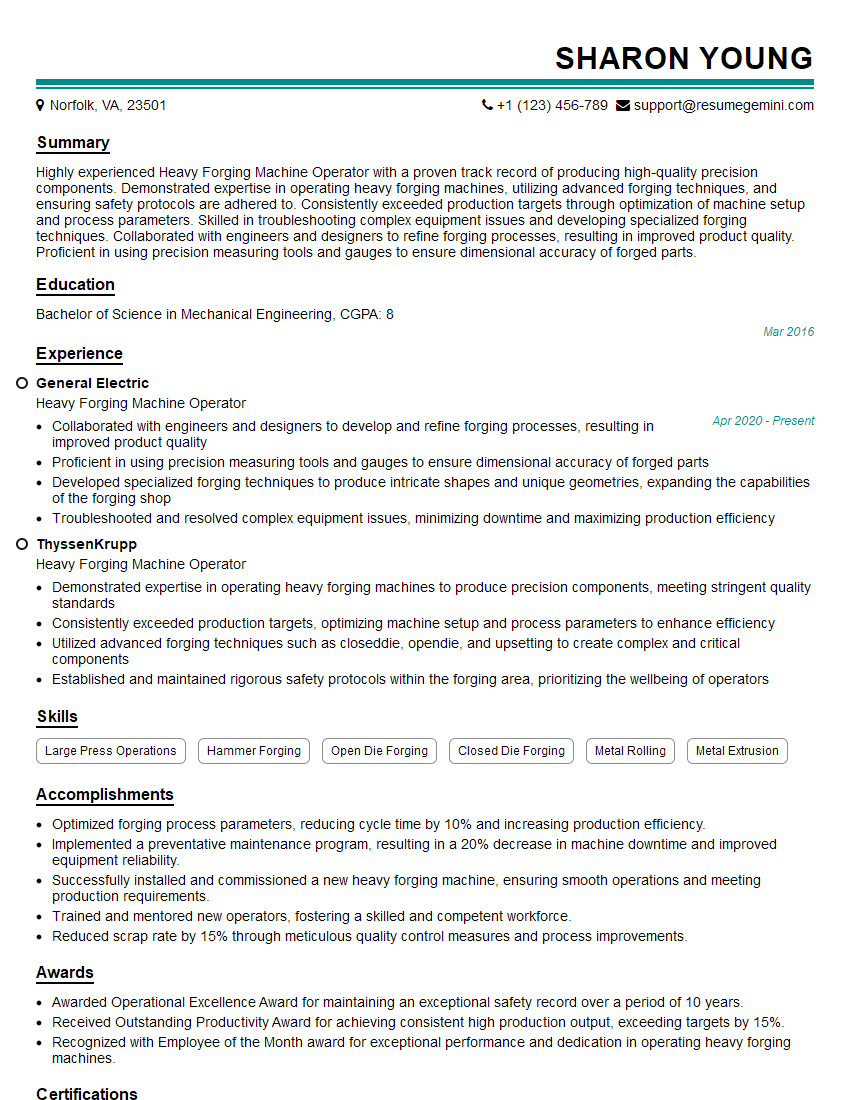

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Forging Machine Operator

1. Explain the process of operating a heavy forging machine?

- Preparing the machine by checking the dies, lubrication system, and hydraulic pressure.

- Loading the heated metal workpiece into the machine.

- Setting the forging parameters, including temperature, pressure, and forging time.

- Operating the machine to forge the workpiece into the desired shape.

- Unloading the finished workpiece from the machine.

2. What are the different types of forging processes?

Hot forging

- Open-die forging: The workpiece is placed between two flat dies and shaped by hammering or pressing.

- Closed-die forging: The workpiece is placed in a closed die cavity and shaped by the application of pressure.

Cold forging

- The workpiece is deformed at room temperature, typically using a press.

3. What are the safety precautions that must be taken when operating a heavy forging machine?

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

- Keeping the work area clean and free of debris.

- Inspecting the machine regularly and reporting any problems to a supervisor.

- Following all operating procedures and safety instructions.

4. How do you troubleshoot common problems with a heavy forging machine?

- Identifying the problem by observing the machine’s behavior and listening for unusual noises.

- Consulting the machine’s manual or troubleshooting guide.

- Performing basic maintenance tasks, such as checking the oil level and tightening loose bolts.

- Contacting a qualified technician if the problem cannot be resolved.

5. What is the importance of maintenance and calibration for a heavy forging machine?

- Regular maintenance helps to prevent breakdowns and extend the machine’s lifespan.

- Calibration ensures that the machine is producing accurate parts.

- Proper maintenance and calibration can help to improve safety and reduce downtime.

6. How do you measure the quality of a forged part?

- Visual inspection for defects, such as cracks or voids.

- Dimensional inspection to ensure that the part meets the specified tolerances.

- Hardness testing to measure the part’s resistance to wear and deformation.

- Magnetic particle testing to detect surface defects.

7. What are the different types of materials that can be forged?

- Steel

- Aluminum

- Copper

- Titanium

- Nickel alloys

8. What are the advantages and disadvantages of forging?

Advantages

- Forging produces strong and durable parts.

- Forging can improve the grain structure of a metal, making it more resistant to wear and tear.

- Forging can be used to create complex shapes that would be difficult or impossible to produce using other methods.

Disadvantages

- Forging can be a slow and expensive process.

- Forging requires specialized equipment and skilled operators.

- Forging can produce waste material.

9. What are the career advancement opportunities for a heavy forging machine operator?

- Supervisor

- Maintenance technician

- Quality control inspector

- Production manager

10. Why are you interested in working as a heavy forging machine operator?

- I am interested in working as a heavy forging machine operator because I enjoy working with my hands and I am fascinated by the forging process.

- I am also confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Forging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Forging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heavy Forging Machine Operators are responsible for operating heavy forging machines to forge metal into desired shapes and sizes. They work in industrial settings and require specialized skills in metalworking and operating heavy machinery.

1. Machine Operation

Operate heavy forging machines, such as presses, hammers, and swaging machines, to forge metal into desired shapes and sizes.

- Set up and calibrate machines according to specifications.

- Load and unload metal into and out of machines.

2. Metalworking Operations

Carry out various metalworking operations, such as forging, swaging, bending, and shearing, to create or modify metal components.

- Heat metal to forging temperatures and manipulate it using forging tools.

- Use hammers, presses, and other equipment to forge metal into desired shapes and sizes.

3. Quality Control

Inspect forged metal components to ensure they meet specifications and quality standards.

- Measure and compare forged components to blueprints or specifications.

- Identify and correct any defects or deviations from specifications.

4. Maintenance

Perform basic maintenance and troubleshooting on heavy forging machines.

- Lubricate and clean machines regularly.

- Identify and troubleshoot minor issues and make necessary repairs.

Interview Tips

Preparing for an interview for a Heavy Forging Machine Operator position requires a combination of technical knowledge and behavioral skills. Here are some tips to help you ace the interview.

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products or services. Research the specific position you are applying for and its key responsibilities.

- Review the company website and social media pages.

- Read industry news and articles related to heavy forging.

2. Highlight Your Technical Skills

Emphasize your experience and skills in operating heavy forging machines. Provide specific examples of your work, such as forging complex shapes or meeting tight tolerances.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your knowledge of different forging techniques and equipment.

3. Demonstrate Your Problem-Solving Abilities

Interviewers want to know that you can handle challenges and solve problems effectively. Describe situations where you identified and resolved issues with forging machines or metalworking operations.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples of how you troubleshoot and resolve issues.

4. Emphasize Safety and Quality

Safety and quality are paramount in heavy forging operations. Highlight your commitment to working safely and ensuring the quality of forged components.

- Discuss your knowledge of safety regulations and your adherence to safety protocols.

- Explain how you maintain quality standards and ensure that forged components meet specifications.

Next Step:

Now that you’re armed with the knowledge of Heavy Forging Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heavy Forging Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini