Are you gearing up for an interview for a Lever Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Lever Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

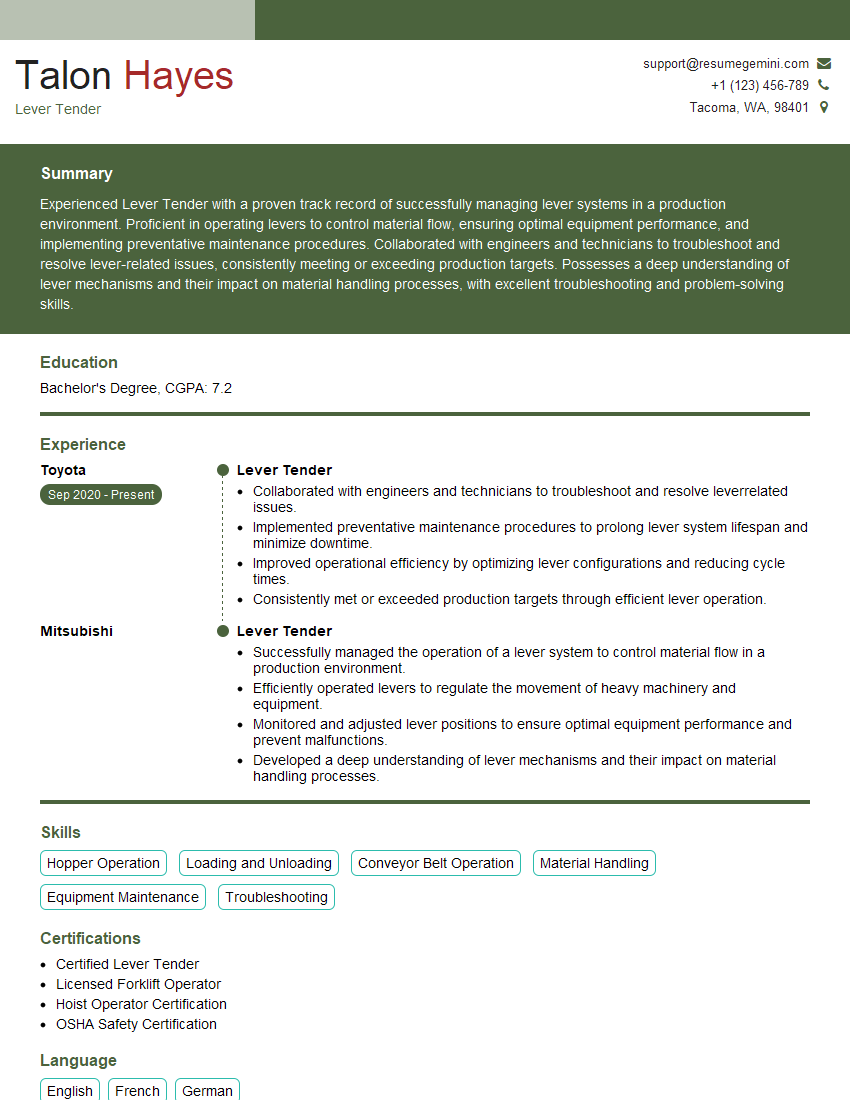

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lever Tender

1. What are the key responsibilities of a Lever Tender?

As a Lever Tender, my primary responsibilities would encompass:

- Operating and maintaining lever machines to precisely control the movement of large, heavy objects.

- Monitoring and adjusting lever mechanisms to ensure smooth and safe operations.

2. Describe the different types of levers used in industrial settings.

Mechanical Levers

- First-class levers: Fulcrum is located between the effort and the load.

- Second-class levers: Load is located between the fulcrum and the effort.

- Third-class levers: Effort is located between the fulcrum and the load.

Hydraulic Levers

- Use pressurized fluid to transmit force.

- Allow for remote operation and greater force multiplication.

3. How do you ensure the safety of yourself and others when working with levers?

Safety is paramount when operating lever machines:

- Regularly inspect levers and mechanisms for damage or wear.

- Follow established operating procedures and wear appropriate safety gear.

- Maintain a safe work area, free from obstructions and potential hazards.

4. What are some common troubleshooting techniques for lever machines?

To effectively troubleshoot lever machines, I employ the following techniques:

- Isolate the issue by checking for loose connections, blockages, or leaks.

- Refer to maintenance manuals and consult with experienced technicians.

- Use diagnostic tools to identify and rectify faults.

5. How do you stay updated on the latest advancements in lever technology?

To remain abreast of advancements:

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Engage in discussions with peers and attend training programs.

6. Describe a situation where you successfully resolved a complex issue with a lever machine.

In a previous role, a lever mechanism on a large crane malfunctioned. I systematically:

- Inspected the machine, identifying a worn gear as the cause.

- Sourced and replaced the gear promptly, ensuring minimal downtime.

- Reassembled the mechanism and conducted thorough testing before resuming operations.

7. How do you handle working in a fast-paced, demanding environment?

In high-pressure environments, I remain composed and focused, prioritizing tasks:

- Establish clear priorities and delegate tasks effectively.

- Communicate regularly with colleagues to ensure coordination and avoid delays.

- Maintain a positive attitude and seek support when necessary.

8. What is your experience with using specialized software and equipment for lever operations?

In my previous role, I utilized:

- Lever control software to monitor and adjust lever positions remotely.

- Diagnostic tools to identify and troubleshoot faults.

- Specialized lifting equipment to ensure safe and precise movement of heavy objects.

9. How do you demonstrate attention to detail and accuracy in your work?

Attention to detail is crucial:

- Thoroughly check lever mechanisms and connections before each operation.

- Follow established procedures precisely to avoid errors.

- Document all inspections and maintenance activities meticulously.

10. What is your understanding of the importance of teamwork in lever operations?

Teamwork is paramount:

- Collaborate effectively with operators, engineers, and maintenance personnel.

- Coordinate tasks and communicate clearly to ensure smooth operations.

- Support colleagues and share knowledge to enhance overall efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lever Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lever Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lever Tenders are responsible for the safe and efficient operation of levers, which are used to lift and move heavy objects in various industrial settings. Their key responsibilities include:

1. Operating Levers

Lever Tenders must be proficient in operating levers to control the movement of heavy objects. This involves using levers to raise, lower, and move objects in a precise and controlled manner.

- Ensuring that levers are properly maintained and calibrated

- Following established safety procedures when operating levers

2. Monitoring Equipment

They are also responsible for monitoring the equipment they operate, including levers, cranes, and hoists. They must be able to identify potential problems or malfunctions and report them promptly.

- Inspecting equipment regularly for signs of wear or damage

- Maintaining equipment records and logs

3. Maintaining Safety Standards

Safety is of utmost importance for Lever Tenders. They must adhere to all applicable safety regulations and guidelines. This involves wearing appropriate safety gear, following established procedures, and maintaining a clean and organized work area.

- Understanding and following industry safety regulations

- Conducting regular safety inspections

4. Troubleshooting and Repairs

Lever Tenders must be able to troubleshoot problems with levers and other equipment. They should be able to perform basic repairs and maintenance tasks, such as replacing cables, adjusting brakes, and lubricating moving parts.

- Diagnosing problems and determining appropriate solutions

- Performing minor repairs and adjustments

Interview Tips

To ace an interview for a Lever Tender position, it is crucial to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Industry

Research the company you are applying to and the industry it operates in. This will give you a better understanding of the company’s culture, values, and the role of a Lever Tender within the organization.

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Practice Your Answers

Practice answering common interview questions related to your skills and experience. This will help you feel more confident and prepared during the interview.

- Review your resume and identify your strengths and weaknesses

- Prepare examples of your work experience that demonstrate your skills

3. Highlight Your Safety Knowledge

Safety is a crucial aspect of a Lever Tender’s role. Emphasize your understanding of safety regulations and procedures. Highlight your experience in following safety guidelines and maintaining a safe work environment.

- Describe your experience with lockout/tagout procedures

- Discuss your knowledge of OSHA regulations and industry best practices

4. Show Your Troubleshooting Abilities

Interviewers will want to know if you can troubleshoot and solve problems. Provide examples of situations where you identified and resolved issues related to levers or other equipment. Describe your approach to problem-solving and the steps you took to find solutions.

- Explain how you diagnosed a problem with a lever and implemented a solution

- Discuss your experience in identifying potential hazards and developing mitigation strategies

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lever Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.