Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Planishing Hammer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

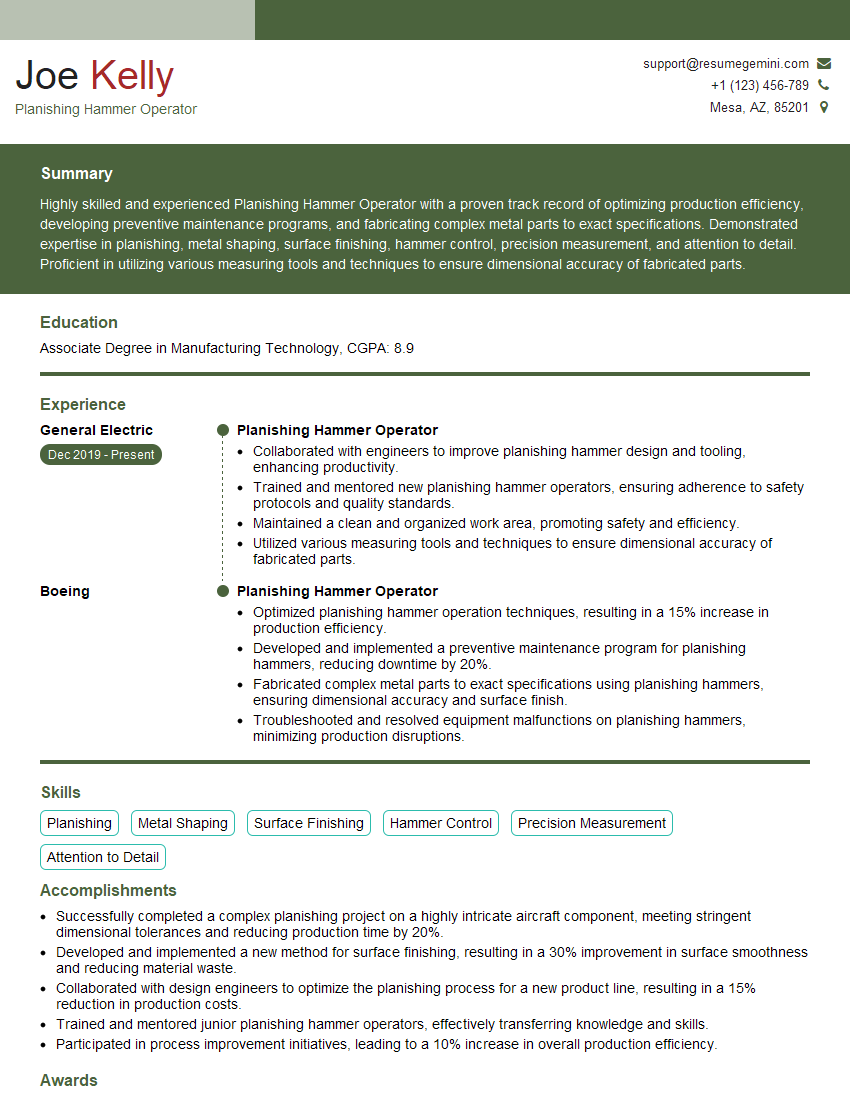

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Planishing Hammer Operator

1. Explain the process of planishing?

Planishing is a metalworking technique used to smooth and harden the surface of a metal sheet. It involves using a planishing hammer to strike the metal in a series of overlapping blows, which helps to work out any imperfections and create a smooth, even surface.

2. What types of planishing hammers are there?

- Hand planishing hammers: These are smaller hammers that are held in the hand and used for detailed work.

- Power planishing hammers: These are larger hammers that are powered by a motor and used for heavier work.

3. What are the different techniques used in planishing?

- Cross-planishing: This technique involves striking the metal in a series of overlapping blows that cross over each other.

- Straight-planishing: This technique involves striking the metal in a series of parallel blows.

- Circular-planishing: This technique involves striking the metal in a series of circular blows.

4. What are the different materials that can be planished?

- Steel

- Aluminum

- Copper

- Brass

5. What are the advantages of planishing?

- Improves the surface finish of the metal

- Hardens the surface of the metal

- Increases the strength of the metal

- Reduces the risk of corrosion

6. What are the disadvantages of planishing?

- Can be time-consuming

- Requires a skilled operator

- Can be expensive

7. How do you set up a planishing hammer?

To set up a planishing hammer, you need to first choose the correct hammer for the job. The size and weight of the hammer will depend on the thickness of the metal you are planishing. Once you have chosen the correct hammer, you need to adjust the settings on the hammer to the desired force and speed.

8. How do you maintain a planishing hammer?

To maintain a planishing hammer, you need to regularly clean and lubricate the hammer. You should also check the hammer for any signs of damage or wear and tear. If you find any damage or wear and tear, you should have the hammer repaired or replaced.

9. What safety precautions should be taken when using a planishing hammer?

- Wear safety glasses

- Wear earplugs

- Wear gloves

- Tie back long hair

- Be aware of your surroundings

10. What are the different applications for planishing?

- Automotive

- Aerospace

- Medical

- Jewelry

- Art

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Planishing Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Planishing Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Planishing Hammer Operators are essential to the production process in a variety of industries. They use specialized hammers to shape and finish metal objects, ensuring that they meet the required specifications.

1. Operate Planishing Hammer

Planishing Hammer Operators are responsible for operating planishing hammers, which are used to shape and finish metal objects.

- Set up and adjust the planishing hammer according to the job specifications.

- Position the metal object on the anvil and operate the hammer to shape and finish it.

2. Inspect and Measure Metal Objects

Planishing Hammer Operators inspect and measure metal objects to ensure that they meet the required specifications.

- Inspect metal objects for defects, such as cracks, dents, or scratches.

- Measure metal objects to ensure that they meet the required dimensions.

3. Maintain Planishing Hammer and Equipment

Planishing Hammer Operators are responsible for maintaining the planishing hammer and other equipment.

- Clean and lubricate the planishing hammer and other equipment.

- Inspect the planishing hammer and other equipment for damage.

4. Follow Safety Procedures

Planishing Hammer Operators must follow all safety procedures to ensure their own safety and the safety of others.

- Wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- Be aware of the location of emergency exits and fire extinguishers.

Interview Tips

Preparing for an interview can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a brief elevator pitch that summarizes your skills and experience.

- Think about specific examples of your work that demonstrate your skills and abilities.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Be sure to arrive at the interview location a few minutes early so that you have time to relax and compose yourself.

4. Be Yourself and Be Confident

It is important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be yourself and let your personality shine through.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic about the position and the company.

Next Step:

Now that you’re armed with the knowledge of Planishing Hammer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Planishing Hammer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini