Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plastic Process Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

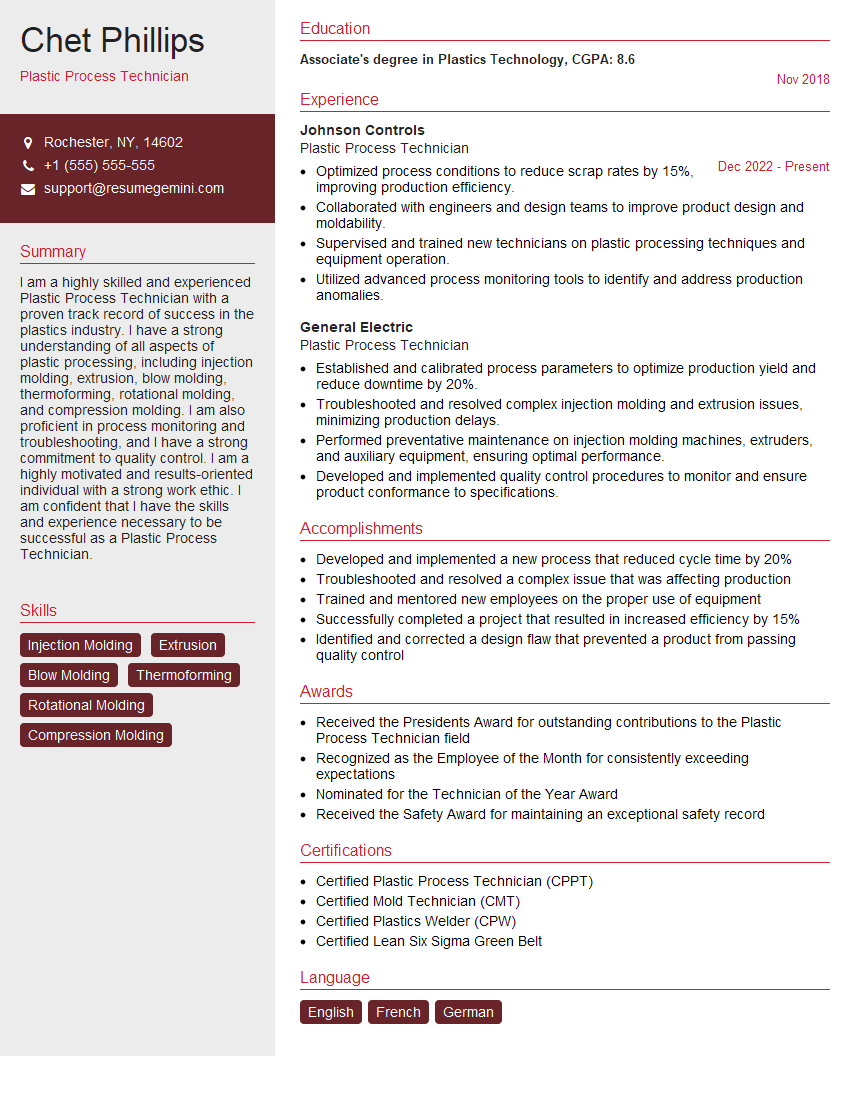

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plastic Process Technician

1. Explain the process of injection molding, including the different stages and equipment used?

Injection molding is a manufacturing process for producing plastic parts. It involves the following stages:

- Clamping: The mold is closed, and the plastic material is injected into the mold cavity.

- Injection: Molten plastic is injected into the mold cavity under high pressure.

- Cooling: The molten plastic is cooled and solidified in the mold cavity.

- Ejection: The finished part is ejected from the mold.

The equipment used in injection molding includes:

- Injection molding machine: This machine clamps the mold, injects the molten plastic, and cools the part.

- Mold: This is a metal tool that forms the shape of the plastic part.

- Plastic material: This is the raw material that is melted and injected into the mold.

2. Describe the different types of plastic materials used in injection molding and their properties?

Thermoplastics

- Can be melted and reshaped multiple times.

- Examples: Polyethylene (PE), Polypropylene (PP), Polystyrene (PS).

Thermosets

- Cannot be melted and reshaped once cured.

- Examples: Epoxy, Polyester, Phenolic.

Elastomers

- Have rubber-like properties.

- Examples: Natural rubber, Styrene-butadiene rubber (SBR).

3. How do you calculate the injection pressure and flow rate for an injection molding process?

The injection pressure and flow rate are determined by the following factors:

- Viscosity of the plastic material: Higher viscosity requires higher pressure.

- Mold cavity size and shape: Larger and more complex cavities require higher flow rates.

- Injection molding machine capacity: The machine must be able to generate sufficient pressure and flow rate.

The following formulas can be used to calculate the injection pressure and flow rate:

- Injection pressure: P = (F/A) + (ηQ/L)

- Injection flow rate: Q = (ΔV/Δt) = (πd²L/4t) * (P – Pamb)/(2ηL)

Where:

- P is the injection pressure

- F is the injection force

- A is the area of the mold cavity

- η is the viscosity of the plastic material

- Q is the injection flow rate

- ΔV is the change in volume of the mold cavity

- Δt is the injection time

- d is the diameter of the injection nozzle

- Pamb is the ambient pressure

4. How do you troubleshoot common problems in the injection molding process, such as warpage, sink marks, and flash?

- Warpage: This can be caused by uneven cooling, shrinkage, or improper mold design.

- Sink marks: These are caused by localized shrinkage of the plastic material.

- Flash: This is excess plastic material that escapes from the mold cavity.

Troubleshooting these problems involves identifying the root cause and implementing corrective measures, such as:

- Adjusting the injection pressure and flow rate

- Modifying the mold design

- Optimizing the cooling process

- Selecting a different plastic material

5. How do you maintain and calibrate injection molding equipment to ensure optimal performance?

Maintaining and calibrating injection molding equipment involves the following steps:

- Regular cleaning and lubrication: This helps to prevent wear and tear and ensure smooth operation.

- Checking for leaks: Leaks can cause pressure loss and affect the quality of the plastic parts.

- Calibrating the injection pressure and flow rate: This ensures that the equipment is operating within the correct parameters.

- Inspecting the mold for damage: Damage to the mold can cause defects in the plastic parts.

6. How do you work effectively in a team environment and communicate technical information to colleagues and supervisors?

- Participate actively in team meetings

- Share knowledge and expertise with colleagues

- Provide clear and concise technical information

- Seek feedback and support from supervisors

7. How do you stay up-to-date on the latest advancements in the plastics industry?

- Attend industry conferences and trade shows

- Read industry publications and journals

- Participate in online forums and discussion groups

- Collaborate with research institutions and universities

8. How do you ensure the quality of plastic parts produced by injection molding?

- Establishing quality control standards

- Inspecting raw materials and finished products

- Using statistical process control techniques

- Implementing corrective actions when necessary

9. How do you optimize the injection molding process to reduce costs and improve efficiency?

- Selecting the right plastic material

- Optimizing the mold design

- Adjusting the injection pressure and flow rate

- Reducing cycle time

- Implementing lean manufacturing techniques

10. How do you handle challenging situations in the workplace, such as equipment malfunctions or production delays?

- Remain calm and assess the situation

- Identify the root cause of the problem

- Develop and implement a solution

- Communicate effectively with colleagues and supervisors

- Learn from the experience and improve processes to prevent future occurrences

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plastic Process Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plastic Process Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plastic Process Technicians are responsible for the daily operation of plastic processing equipment. They ensure that the machinery is running safely and efficiently, and that the products being produced meet the required specifications.

1. Machine Operation

Plastic Process Technicians operate a variety of machines, including extruders, injection molding machines, and thermoforming machines. They are responsible for setting up the machines, monitoring their operation, and making adjustments as needed.

- Set up and operate plastic processing equipment, such as extruders, injection molding machines, and thermoforming machines

- Monitor the operation of the equipment and make adjustments as needed

2. Quality Control

Plastic Process Technicians are responsible for ensuring that the products being produced meet the required specifications. They inspect the products for defects, and they make adjustments to the machines as needed to correct any problems.

- Inspect products for defects and make adjustments to the machines as needed

- Ensure that the products meet the required specifications

3. Maintenance

Plastic Process Technicians are responsible for performing routine maintenance on the equipment they operate. They clean the machines, lubricate the moving parts, and make minor repairs.

- Perform routine maintenance on the equipment

- Clean the machines, lubricate the moving parts, and make minor repairs

4. Safety

Plastic Process Technicians are responsible for following all safety procedures. They wear appropriate safety gear, and they are aware of the hazards associated with the equipment they operate.

- Follow all safety procedures

- Wear appropriate safety gear

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

The more you know about the company and the position, the better prepared you’ll be to answer questions and make a good impression. Take some time to research the company’s website, LinkedIn page, and Glassdoor reviews. This will give you a good understanding of the company’s culture, values, and what they’re looking for in a candidate.

- Research the company’s website, LinkedIn page, and Glassdoor reviews

- Learn about the company’s culture, values, and what they’re looking for in a candidate

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice your answers to common interview questions

- Deliver your answers confidently and concisely

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your relevant experience and how it qualifies you for the position. If you don’t have any direct experience in the plastics industry, you can highlight your transferable skills, such as your ability to operate machinery, work in a team, and solve problems.

- Talk about your relevant experience and how it qualifies you for the position

- Highlight your transferable skills

4. Ask Questions

Asking questions at the end of the interview shows that you’re interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What are the company’s goals for the next year?”.

- Ask questions at the end of the interview

- Show that you’re interested in the position and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plastic Process Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!