Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rivet Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

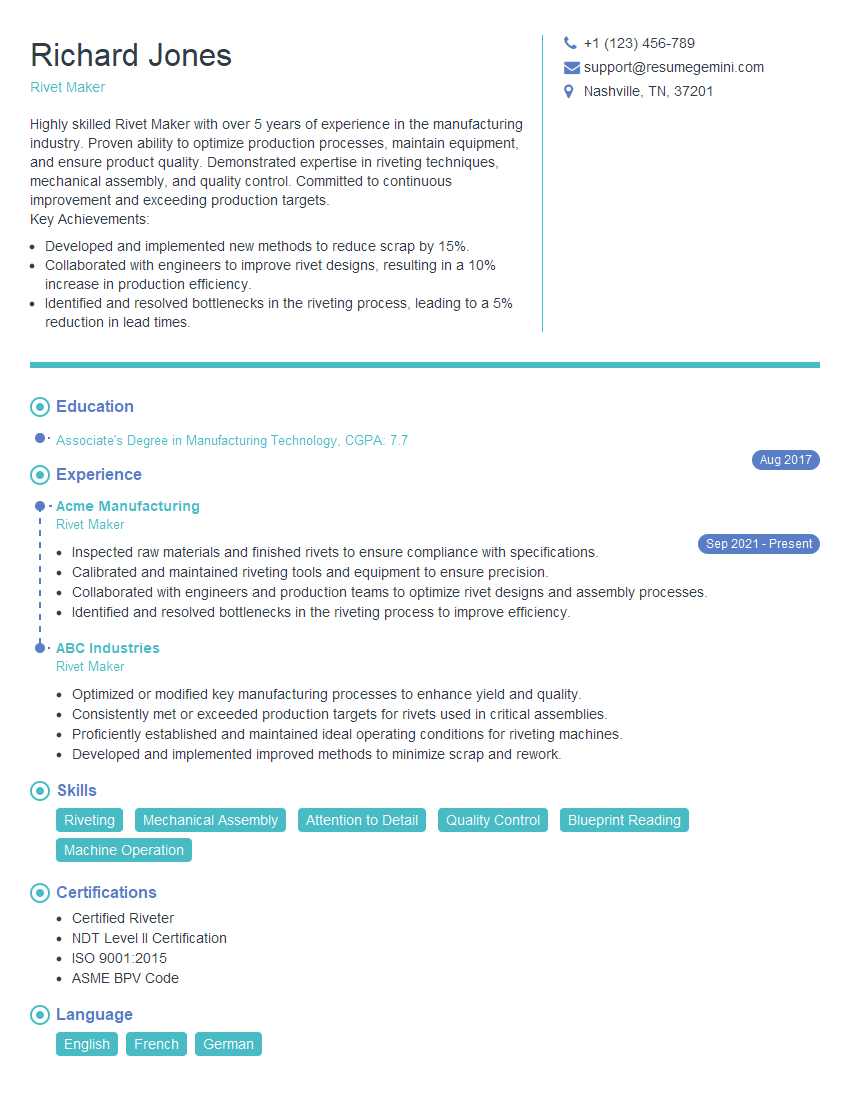

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rivet Maker

1. Explain the process of cold riveting vs hot riveting?

- Cold riveting is a process of joining two or more metal sheets together by applying pressure without the use of heat.

- Hot riveting is a process of joining two or more metal sheets together by applying heat and pressure.

2. What are the different types of rivet heads?

Countersunk Head

- Used when a flush surface is required.

- Countersunk into the material.

Pan Head

- Most common type of rivet head.

- Has a slightly rounded head.

Round Head

- Similar to pan head but has a more rounded head.

- Used in applications where a high clamping force is required.

Button Head

- Has a large, flat head.

- Used in applications where a large bearing surface is required.

3. What is the difference between a solid rivet and a tubular rivet?

- Solid rivets are made from a single piece of metal and have a solid shank.

- Tubular rivets have a hollow shank and are made from two pieces of metal that are joined together.

4. What are the advantages and disadvantages of using rivets?

Advantages:

- Strong and durable.

- Relatively easy to install.

- Can be used to join a variety of materials.

Disadvantages:

- Can be time-consuming to install.

- Can create a visible joint.

- Can be difficult to remove.

5. What are the different types of rivet setting tools?

Manual Rivet Tools

- Used for small-scale riveting operations.

- Operated by hand.

Pneumatic Rivet Tools

- More powerful than manual rivet tools.

- Operated by compressed air.

Hydraulic Rivet Tools

- Most powerful type of rivet setting tool.

- Operated by hydraulic pressure.

6. What are the safety precautions that should be taken when using rivet setting tools?

- Always wear safety glasses.

- Make sure the rivet setting tool is in good working condition.

- Do not use the rivet setting tool on live electrical circuits.

- Keep the work area clean and free of debris.

7. How do you determine the correct rivet size for a given application?

- Consider the thickness of the materials being joined.

- Consider the load that the joint will be subjected to.

- Refer to a rivet size chart or consult with a manufacturer.

8. What are the common defects that can occur when riveting?

- Loose rivets.

- Misaligned rivets.

- Broken rivets.

- Overdriven rivets.

- Underdriven rivets.

9. How do you inspect a riveted joint for quality?

- Visually inspect the joint for any obvious defects.

- Use a hammer to tap on the rivets and listen for any loose rivets.

- Use a magnetic particle inspection to check for any cracks or other defects in the rivets.

10. What are the latest trends in riveting technology?

- Development of new materials and alloys for rivets.

- Development of new rivet setting tools.

- Use of robotics and automation in riveting operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rivet Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rivet Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rivet Makers are responsible for producing rivets, which are essential components used to join various materials together. Their primary tasks involve operating riveting machines and ensuring that the rivets meet the required specifications.

1. Machine Operation

Rivet Makers set up and operate riveting machines. They adjust settings such as temperature, pressure, and dwell time, depending on the type of rivet being produced and the materials being joined.

- Configure and calibrate riveting machines

- Monitor machine performance and make adjustments as needed

2. Production Management

Rivet Makers manage the entire production process, ensuring that rivets are made efficiently according to specifications. They monitor production rates, maintain equipment, and troubleshoot any issues that may arise.

- Plan and schedule production operations

- Control inventory and replenish supplies

- Resolve production delays and quality issues

3. Quality Control

Rivet Makers inspect the finished rivets to ensure that they meet the required specifications and quality standards. They use measuring tools and gauges to check dimensions, strength, and surface finish.

- Conduct visual and dimensional inspections

- Perform destructive and non-destructive tests

- Maintain quality records and documentation

4. Safety Compliance

Rivet Makers prioritize safety in the workplace, following established procedures and wearing appropriate personal protective equipment. They keep their work areas clean and organized, and report any potential hazards or incidents.

- Follow safety regulations and guidelines

- Identify and mitigate potential risks

- Maintain a clean and organized work environment

Interview Tips

Preparing for a Rivet Maker interview involves understanding the key job responsibilities and essential skills required. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Learn about the company’s products, services, and industry landscape. This will demonstrate your interest in the position and the company’s mission.

- Visit the company website and social media pages

- Read industry publications and news articles

- Network with professionals in the field

2. Practice Your Answers

Prepare thoughtful responses to common interview questions. Consider using the STAR method (Situation, Task, Action, Result) to highlight your skills and experiences.

- Anticipate questions about your rivet making experience, attention to detail, and problem-solving abilities

- Use specific examples from your work history to demonstrate your capabilities

3. Highlight Relevant Skills

Emphasize skills essential for the Rivet Maker role, such as machine operation, quality control, and safety compliance. Quantify your achievements whenever possible.

- Describe your experience operating riveting machines and any specific techniques you have mastered

- Explain your quality control procedures and how you ensure the accuracy and consistency of rivets

- Share examples of how you have maintained a safe and efficient work environment

4. Demonstrate Problem-Solving Abilities

Interviewers often ask about your approach to solving problems. Provide examples of how you have identified and resolved issues in previous roles.

- Discuss a time when you encountered a production issue and how you worked with others to find a solution

- Describe how you handle tight deadlines and unexpected challenges

5. Be Enthusiastic and Confident

Convey your passion for rivet making and your eagerness to contribute to the company. Show that you are confident in your abilities and ready to take on the challenges of the role.

- Express your interest in the position and why you are a suitable match

- Ask insightful questions about the company and the role to demonstrate your engagement

- Thank the interviewer for their time and consideration

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rivet Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rivet Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.