Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Steam Hammer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

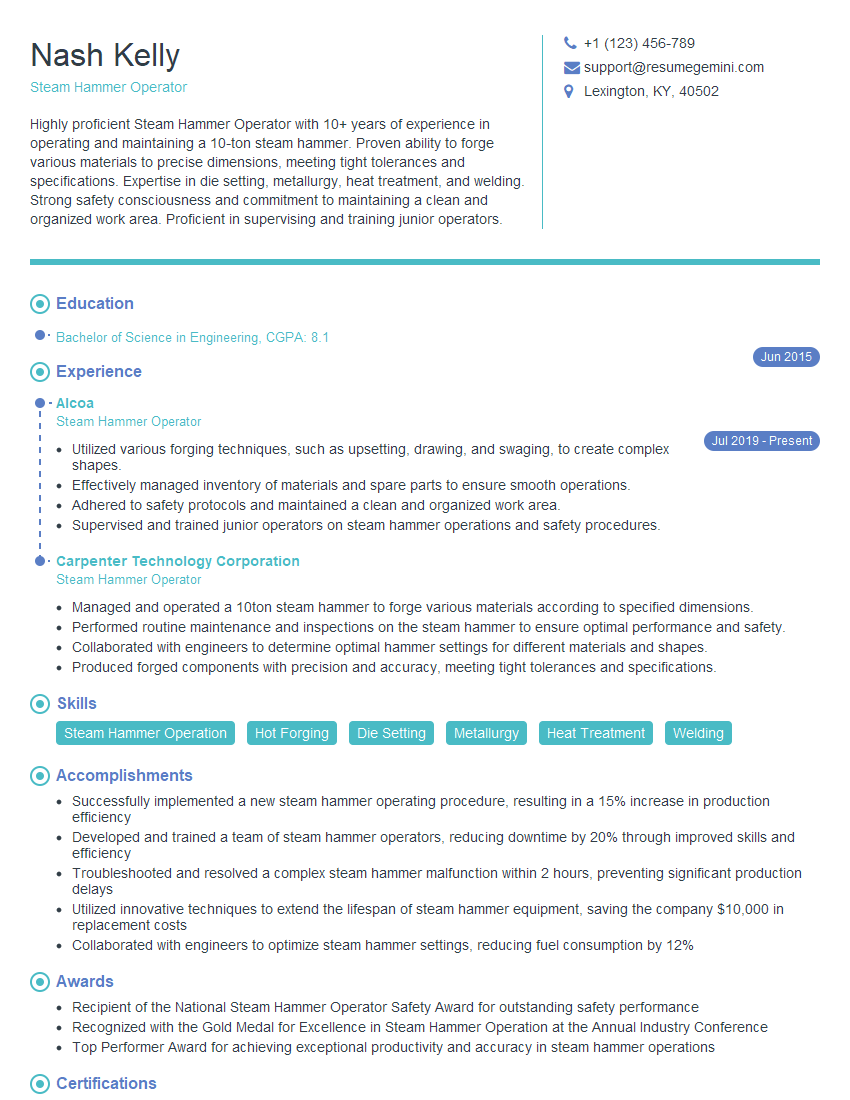

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steam Hammer Operator

1. What are the different types of steam hammers and their applications?

Steam hammers are primarily classified into two types:

- Single-acting steam hammers: These hammers use steam pressure to drive the piston upward and gravity to bring it down. They are suitable for lighter forging operations.

- Double-acting steam hammers: In these hammers, steam pressure is used to drive the piston both upward and downward. They are used for heavier forging applications.

2. What are the key operating parameters of a steam hammer that need to be monitored and controlled?

- Steam pressure

- Hammer stroke length

- Hammer speed

- Die temperature

- Workpiece temperature

3. Explain the process of setting up a steam hammer for a forging operation.

Setting up a steam hammer for a forging operation involves several steps:

- Die selection: Selecting the appropriate dies for the desired forging shape.

- Die installation: Installing the dies into the hammer’s anvil and ram.

- Workpiece preparation: Heating the workpiece to the desired forging temperature.

- Hammer adjustment: Setting the hammer’s stroke length, speed, and steam pressure according to the workpiece and forging requirements.

4. What are the safety precautions that should be taken when operating a steam hammer?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure that the hammer is properly maintained and inspected regularly.

- Never operate the hammer under excessive steam pressure.

- Keep the work area clean and clear of obstructions.

- Always be aware of the hammer’s position and never stand directly in its path.

5. What are the common maintenance procedures required for a steam hammer?

- Regular lubrication of all moving parts

- Inspection and replacement of worn or damaged parts

- Calibration of pressure gauges and other instruments

- Troubleshooting and repair of any malfunctions

- Periodic overhauls to ensure optimal performance and safety

6. Explain how to troubleshoot a steam hammer that is not striking properly.

- Check the steam pressure and ensure it is within the recommended range.

- Inspect the valve system for any leaks or blockages.

- Examine the piston and cylinder for any damage or wear.

- Check the dies for any misalignment or damage.

- If the issue persists, consult with a qualified technician.

7. Describe the different forging techniques that can be performed using a steam hammer.

- Open die forging: Using flat or shaped dies to shape the workpiece between the hammer and anvil.

- Closed die forging: Using closed dies to create specific shapes or impressions in the workpiece.

- Roll forging: Using cylindrical dies to reduce the thickness or diameter of the workpiece.

- Upset forging: Using a top and bottom die to increase the cross-sectional area of the workpiece.

8. What are the quality control measures that should be implemented during steam hammer forging?

- Visual inspection for any defects or imperfections

- Dimensional measurements to ensure compliance with specifications

- Hardness testing to verify the desired material properties

- Non-destructive testing (NDT) to detect any internal flaws

- Maintaining accurate records of all inspections and test results

9. How do you maintain a clean and organized work area around the steam hammer?

- Regularly sweep and clean the floor to remove debris.

- Keep all tools and materials organized and in their designated places.

- Dispose of waste materials promptly and properly.

- Maintain proper ventilation to minimize dust and fumes.

- Inspect the work area regularly for any potential hazards and address them promptly.

10. What are your strengths and weaknesses as a Steam Hammer Operator?

Strengths:

- Proficient in operating and maintaining steam hammers

- Strong understanding of forging techniques and metallurgy

- Excellent attention to detail and quality control

- Ability to work independently and as part of a team

- Committed to safety and maintaining a clean and organized work area

Weaknesses:

- Relatively new to the industry with limited experience in certain specialized forging applications

- Still developing expertise in troubleshooting complex hammer malfunctions

- Working towards obtaining industry certifications to further enhance my qualifications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steam Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steam Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Steam Hammer Operator

Steam hammer operators are highly skilled workers who use their expertise and technical acumen to shape and forge metal components using a steam-powered hammer. Their typical responsibilities include:

1. Operating and Maintaining Steam Hammer Equipment

The primary responsibility of a steam hammer operator is to operate and maintain the steam hammer equipment. They ensure the machine is well-lubricated, regularly inspect it to identify maintenance needs, and perform repairs when necessary to keep the equipment running smoothly.

2. Forging and Shaping Metal

Using the steam hammer, operators shape and forge metal components by heating the workpiece to a high temperature and then using the hammer to shape it into the desired form. They may use various techniques, such as forging, bending, or riveting, to achieve the required shape and dimensions.

3. Reading and Interpreting Blueprints and Work Orders

Operators read and interpret blueprints and work orders to understand the specifications for the metal components they need to forge. They ensure that the finished product meets the required dimensions, tolerances, and quality standards.

4. Maintaining a Safe Work Environment

Safety is paramount in the operation of steam hammers. Operators are responsible for adhering to safety regulations, wearing appropriate personal protective equipment, and ensuring the work area is safe for themselves and others.

5. Troubleshooting and Problem Solving

When problems arise with the steam hammer equipment or the workpiece, operators use their knowledge and problem-solving skills to identify and resolve the issue. They may consult with supervisors or mechanics to seek assistance when necessary.

Interview Tips for a Steam Hammer Operator

Preparing for a steam hammer operator interview requires a combination of technical expertise, industry knowledge, and a confident demeanor. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and the industry sector they operate in. Tailoring your answers to the company’s needs and the job requirements will show the interviewer that you have put in the effort.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and previous experience in operating and maintaining steam hammer equipment. Provide specific examples of how you have successfully shaped and forged metal components, ensuring accuracy and meeting quality standards.

3. Showcase Your Problem-Solving Abilities

Interviewers are keen on assessing your problem-solving capabilities. Share instances where you have faced challenges with steam hammer equipment or workpiece issues and how you used your analytical skills to resolve them effectively.

4. Convey Your Safety Mindset

Stress your commitment to safety and your understanding of the importance of adhering to safety regulations and wearing appropriate personal protective equipment in the operation of steam hammer equipment.

5. Practice Your Communication Skills

Steam hammer operators need to be able to communicate clearly and effectively. Practice answering questions concisely and confidently. Be prepared to articulate your technical knowledge and demonstrate your ability to explain complex concepts in a clear and understandable manner.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Steam Hammer Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.