Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Swager Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

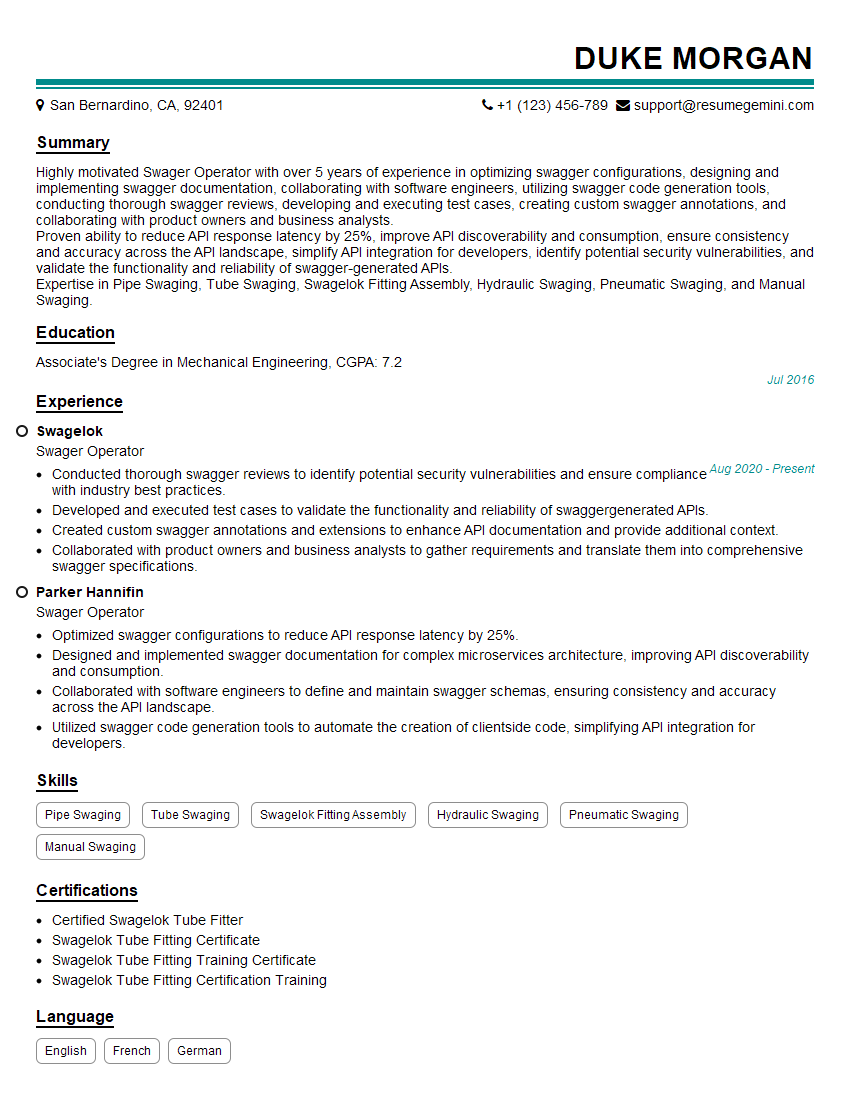

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swager Operator

1. What are the key responsibilities of a Swager Operator?

As a Swager Operator, my key responsibilities will be:

- Monitoring and controlling swaging machines to produce high-quality products.

- Ensuring that all safety protocols are followed during operation.

- Performing maintenance and calibration on swaging machines to maintain optimal performance.

- Troubleshooting and resolving any issues that arise during the swaging process.

- Collaborating with other team members to ensure smooth production flow.

2. Describe the different types of swaging machines and their applications?

Electrical swaging machines

- Use электричество to power the swaging process.

- Offer precise control and high repeatability.

- Suitable for high-volume production and complex swaging operations.

Hydraulic swaging machines

- Use hydraulic pressure to generate the swaging force.

- Provide high power and can handle large diameters and thick materials.

- Suitable for heavy-duty applications and forging operations.

Pneumatic swaging machines

- Use compressed air to power the swaging process.

- Offer portability and can be used in remote locations.

- Suitable for light-duty applications and small-scale production.

3. What are the critical parameters to consider when selecting a swaging machine?

- Material type and thickness

- Desired swage shape and size

- Production volume and cycle time

- Availability of power and space

- Cost and maintenance requirements

4. How do you ensure the quality of the swaged products?

- Regularly calibrate and maintain the swaging machines.

- Inspect the raw materials and finished products for defects.

- Follow established quality control procedures.

- Use appropriate tooling and lubricants.

- Monitor and adjust process parameters as needed.

5. What safety precautions should be taken when operating a swaging machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Inspect the machine and tooling before each use.

- Secure the workpiece properly.

- Keep hands and other body parts away from moving parts.

- Follow lockout/tagout procedures when performing maintenance or repairs.

6. How do you troubleshoot common problems that occur during the swaging process?

- Improper swage shape or size: Check the tooling, machine settings, or material properties.

- Surface defects: Inspect the tooling for wear or damage, adjust process parameters, or use a different lubricant.

- Machine malfunctions: Consult the manufacturer’s manual, perform basic troubleshooting steps, and contact a qualified technician if necessary.

- Material damage: Verify the material properties, adjust process parameters, or consider using a different material.

- Excessive noise or vibration: Check the alignment of the tooling, inspect for loose components, or perform maintenance on the machine.

7. What is a progressive swaging process, and what are its advantages?

A progressive swaging process involves multiple swaging steps performed in sequence to gradually form the desired shape.

- Advantages:

- Increased production speed

- Improved precision and repeatability

- Reduced material waste

- Can handle complex shapes and tight tolerances

8. What are the different types of tooling used in swaging operations?

- Dies: Form the desired shape in the workpiece.

- Punches: Exert pressure to create the swage.

- Mandrels: Support the workpiece during the swaging process.

- Locating pins: Ensure accurate alignment of the workpiece and tooling.

- Guides: Control the movement of the tooling.

9. How do you calculate the swaging force required for a specific operation?

The swaging force (F) can be calculated using the following formula:

- F = Y * A * t

- Where:

- Y is the yield strength of the material

- A is the cross-sectional area of the workpiece

- t is the thickness of the workpiece

10. What is the difference between cold swaging and hot swaging?

- Cold swaging: Performed at room temperature, resulting in work hardening of the material.

- Hot swaging: Performed at elevated temperatures, allowing for greater deformation and reduced work hardening.

- Cold swaging is typically used for smaller parts and higher precision, while hot swaging is suitable for larger parts and heavier deformations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swager Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swager Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Swager Operator is responsible for the safe and efficient operation of swaging machines, which are used to shape and join metal components.

1. Machine Operation

The primary responsibility of a Swager Operator is to set up, calibrate, and operate swaging machines.

- Set up and adjust swaging machines.

- Load and unload metal components from the machine.

- Monitor the machine during operation to ensure that it is functioning properly.

2. Quality Control

Swager Operators are also responsible for ensuring that the swaged components meet the required quality standards.

- Inspect swaged components for defects.

- Make adjustments to the machine or process as needed to correct defects.

- Maintain records of quality control inspections.

3. Maintenance

Swager Operators are also required to perform basic maintenance on their machines.

- Clean and lubricate the machine.

- Replace worn or damaged parts.

- Troubleshoot and repair minor malfunctions.

4. Safety

Swager Operators must adhere to all safety regulations and procedures.

- Wear appropriate safety gear.

- Follow lockout/tagout procedures.

- Report any unsafe conditions or practices.

Interview Tips

Interview Tips for Swager Operators

1. Preparation

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job. You should also practice answering common interview questions.

- Research the company and the position.

- Practice answering common interview questions.

- Prepare questions to ask the interviewer.

2. Appearance and Behavior

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Dress professionally.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

3. During the Interview

During the interview, be clear and concise in your answers. Use specific examples to demonstrate your skills and experience. Be enthusiastic and positive, and show the interviewer that you are eager to learn and grow.

- Be clear and concise in your answers.

- Use specific examples to demonstrate your skills and experience.

- Be enthusiastic and positive.

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation and reinforce your interest in the position.

- Send a thank-you note to the interviewer.

- Reiterate your interest in the position.

- Ask about the next steps in the hiring process.

Next Step:

Now that you’re armed with the knowledge of Swager Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Swager Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini