Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Upset Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

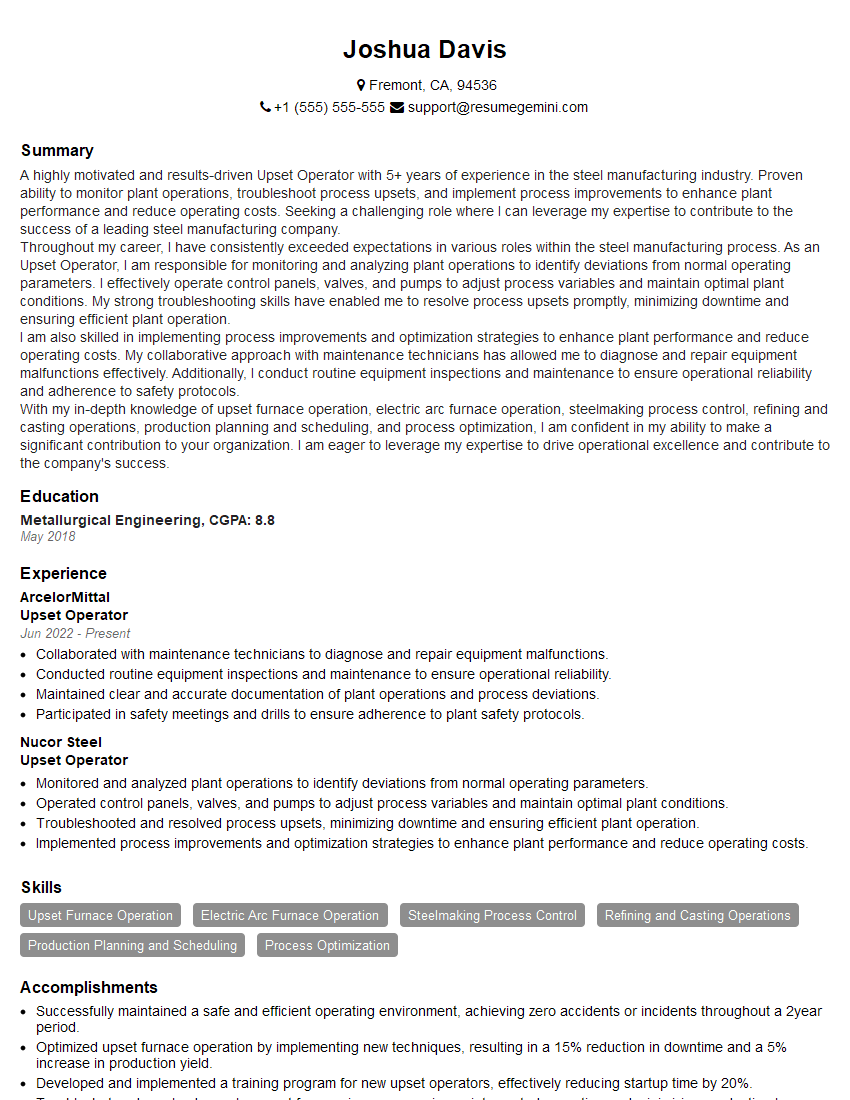

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Upset Operator

1. What is the purpose of a gas compressor?

The purpose of a gas compressor is to increase the pressure of a gas or vapor by reducing its volume. This is typically done through the use of a piston, diaphragm, or rotary mechanism.

2. What are the different types of gas compressors?

Reciprocating compressors:

- These compressors use a piston and cylinder to compress gas.

- They are typically used for low-pressure applications.

Rotary compressors:

- These compressors use a rotating impeller to compress gas.

- They are typically used for high-pressure applications.

Centrifugal compressors:

- These compressors use a centrifugal force to compress gas.

- They are typically used for high-volume applications.

3. What are the factors that affect the efficiency of a gas compressor?

- Type of compressor

- Operating pressure

- Gas flow rate

- Inlet and outlet temperatures

4. What are the common maintenance procedures for a gas compressor?

- Inspecting and cleaning the compressor

- Replacing the oil and filters

- Checking and adjusting the compressor’s settings

- Troubleshooting and repairing any problems

5. What are the safety precautions that should be taken when operating a gas compressor?

- Wear appropriate safety gear

- Follow the manufacturer’s instructions

- Inspect the compressor before each use

- Do not operate the compressor in a hazardous environment

6. What are the troubleshooting steps for a gas compressor that is not working properly?

- Check the power supply

- Check the inlet and outlet valves

- Check the oil level

- Check the compressor’s settings

- Contact a qualified technician if the problem cannot be resolved

7. What are the different types of gas compressor lubricants?

Mineral oils:

- These are the most common type of lubricant used in gas compressors.

- They are inexpensive and readily available.

Synthetic oils:

- These lubricants are more expensive than mineral oils, but they offer a number of advantages, such as improved performance and longer life.

Polyalkylene glycols (PAGs):

- These lubricants are designed for use in high-pressure and high-temperature applications.

8. What are the advantages of using a variable speed drive (VSD) on a gas compressor?

- Improved efficiency

- Reduced energy consumption

- Extended compressor life

- Reduced noise levels

9. What are the different types of gas compressor control systems?

Manual control:

- The compressor is started and stopped manually.

Automatic control:

- The compressor is started and stopped automatically based on a setpoint.

- There are a variety of automatic control systems available, such as pressure control, temperature control, and flow control.

Computer control

- The compressor is controlled by a computer.

10. What are the benefits of using a gas compressor monitoring system?

- Improved efficiency

- Reduced energy consumption

- Extended compressor life

- Reduced maintenance costs

- Improved safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Upset Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Upset Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Upset Operator is responsible for monitoring and controlling plant operations during upset conditions. They must have a thorough understanding of plant processes, equipment, and safety procedures to ensure the safe and efficient operation of the plant.

1. Monitor Plant Operations

Upset Operators continuously monitor plant operations to identify any deviations from normal operating conditions. They use a variety of instruments and control systems to track process variables, such as temperature, pressure, flow, and level.

- Identify and analyze deviations from normal operating conditions.

- Monitor control systems and make adjustments to maintain process variables within acceptable limits.

- Respond to alarms and take appropriate action to prevent or mitigate upsets.

2. Control Plant Equipment

Upset Operators control plant equipment to maintain process variables within acceptable limits. They use a variety of control systems, such as manual, automatic, and computer-based systems, to adjust equipment settings and maintain stable operating conditions.

- Operate control valves, pumps, compressors, and other equipment to control process variables.

- Adjust control system settings to optimize plant performance.

- Maintain and calibrate control equipment to ensure accurate and reliable operation.

3. Perform Troubleshooting

Upset Operators troubleshoot plant upsets to identify and correct the root cause of the problem. They use a variety of techniques, such as data analysis, equipment inspections, and process simulations, to identify and resolve issues.

- Analyze data and identify trends to identify potential problems.

- Inspect equipment and identify signs of wear, damage, or malfunction.

- Perform process simulations to test different scenarios and identify potential solutions.

4. Maintain Safety

Upset Operators are responsible for maintaining a safe working environment. They follow all safety procedures and use appropriate personal protective equipment (PPE) to protect themselves and others from hazards.

- Follow all safety procedures and wear appropriate PPE.

- Identify and assess potential hazards and take steps to mitigate risks.

- Respond to emergencies and take appropriate action to protect personnel and property.

Interview Tips

Preparing for an interview for an Upset Operator position can be daunting. However, by following these tips and hacks, you can increase your chances of success.

1. Research the Company and Position

Take the time to research the company you are applying to and the specific Upset Operator position. This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company and the Upset Operator profession.

- Network with people in your field or who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle stress and pressure?

- What is your experience with plant upsets?

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Upset Operator position. This includes your technical skills, your experience with plant upsets, and your safety record.

- Quantify your accomplishments and provide specific examples of your work.

- Use action verbs to describe your skills and experience.

- Be prepared to discuss your experience with different types of plant upsets.

4. Be Prepared to Ask Questions

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the Upset Operator position.

- Ask about the company’s plans for the future.

Next Step:

Now that you’re armed with the knowledge of Upset Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Upset Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini