Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steel Shot Header Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steel Shot Header Operator so you can tailor your answers to impress potential employers.

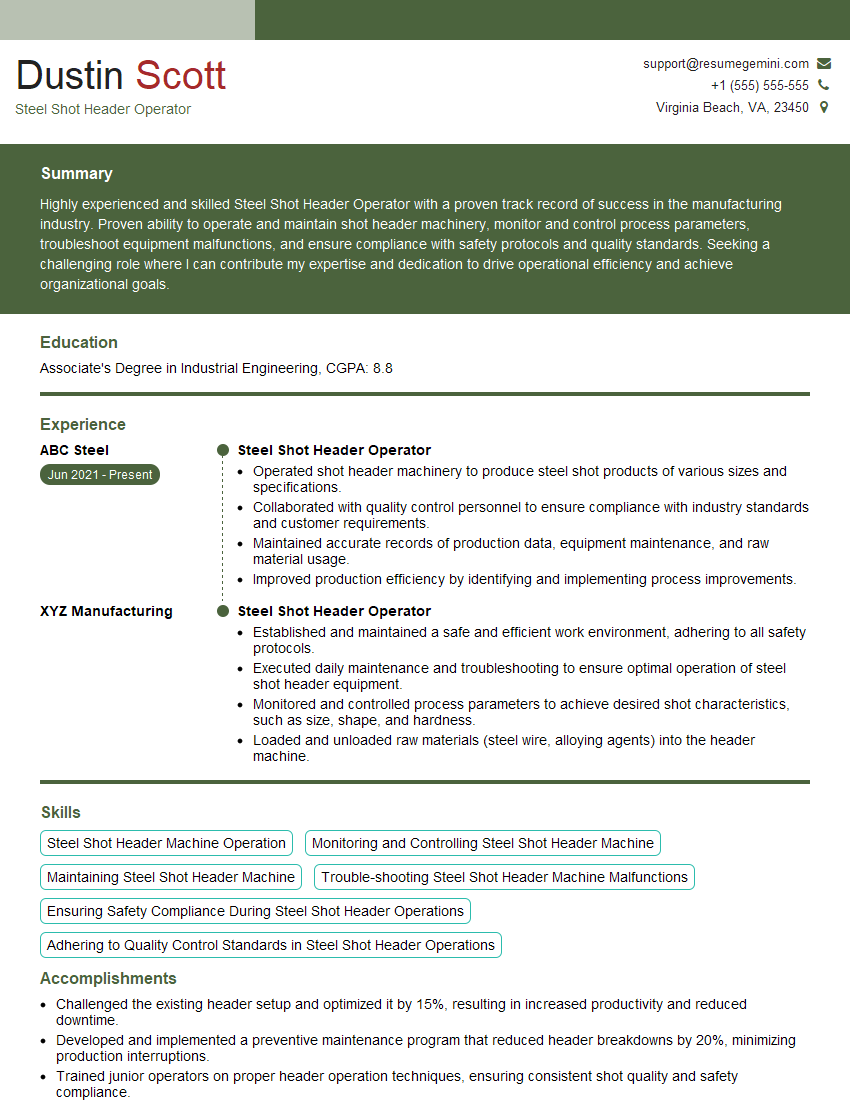

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Shot Header Operator

1. Explain the process of setting up and operating a steel shot header machine?

- Inspect the machine for wear or damage and lubricate as necessary

- Install the tooling and adjust the settings according to the job specifications

- Load the raw material into the machine and start the cycle

- Monitor the machine during operation and make adjustments as needed

- Remove the finished product and inspect it for quality

2. What types of problems can occur while operating a steel shot header machine?

Mechanical problems

- Tool wear or breakage

- Malfunctioning of the machine

Material problems

- Inconsistent raw material quality

- Incorrect material specifications

Process problems

- Incorrect tooling settings

- Improper lubrication

3. How do you troubleshoot and resolve problems with a steel shot header machine?

- Identify the problem and determine its cause

- Take corrective action to resolve the problem

- Test the machine to ensure that the problem has been resolved

4. What are the safety procedures that must be followed when operating a steel shot header machine?

- Wear proper safety gear, including gloves, safety glasses, and earplugs

- Keep the work area clean and clear of debris

- Do not operate the machine while under the influence of drugs or alcohol

- Follow all lockout/tagout procedures

5. What types of maintenance are required for a steel shot header machine?

- Daily maintenance: Lubrication, inspection of tooling, and cleaning

- Weekly maintenance: More thorough inspection of the machine, including checking for wear or damage

- Monthly maintenance: Major overhaul of the machine, including replacement of worn parts

6. What are the different types of steel shot headers available?

- Cold heading

- Hot heading

- Roll forging

7. What are the advantages and disadvantages of each type of steel shot header?

Cold heading

- Advantages: High precision, low cost

- Disadvantages: Limited to smaller parts, can weaken the material

Hot heading

- Advantages: Can produce larger parts, stronger than cold heading

- Disadvantages: Lower precision, more expensive

Roll forging

- Advantages: Can produce complex shapes, high strength

- Disadvantages: Slow process, expensive

8. What are the factors that affect the quality of steel shot headers?

- Material quality

- Machine settings

- Tooling

- Operator skill

- Process control

9. What are the quality control procedures for steel shot headers?

- Dimensional inspection

- Visual inspection

- Hardness testing

- Tensile testing

10. What are the challenges of operating a steel shot header machine?

- High noise levels

- Repetitive work

- Potential for injury

- Quality control

- Keeping up with production demands

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Shot Header Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Shot Header Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Shot Header Operators play a crucial role in manufacturing steel shot used in various applications, such as shot blasting and peening. Their key responsibilities include:

1. Machine Operation and Monitoring

Operate and monitor steel shot heading machines to produce shot within specified quality standards.

- Set up and adjust machine parameters, such as feed rate, temperature, and pressure.

- Monitor machine performance and make necessary adjustments to ensure optimal production.

2. Quality Control

Inspect and test steel shot to ensure it meets the required specifications.

- Conduct visual and physical inspections for defects, such as cracks, inclusions, and size deviations.

- Perform hardness and sphericity tests to verify the shot’s mechanical properties.

3. Equipment Maintenance

Perform routine maintenance and troubleshooting on steel shot heading machines and auxiliary equipment.

- Replace worn or damaged parts, such as dies, nozzles, and bearings.

- Lubricate moving components and clean machines to prevent malfunctions.

4. Production and Process Optimization

Monitor production processes and identify areas for improvement to enhance efficiency and reduce downtime.

- Analyze machine data and process parameters to optimize production settings.

- Implement process improvements to increase yield, reduce waste, and improve shot quality.

5. Health and Safety Compliance

Follow all health and safety regulations and procedures related to the operation of steel shot heading machines.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Maintain a clean and organized work environment to prevent accidents and equipment damage.

Interview Preparation Tips

To ace an interview for the position of Steel Shot Header Operator, it is essential to prepare thoroughly and showcase your relevant skills and experience.

1. Research the Company and Position

Before the interview, take the time to research the hiring company and the specific job role. Understand their industry, product line, and company culture. It will help you align your answers and demonstrate your interest in the opportunity.

- Visit the company website and social media pages to gather information.

- Read industry publications and news articles related to the company’s business.

2. Highlight Relevant Skills and Experience

Review the job description carefully and identify the key skills and experience required for the position. Tailor your resume and cover letter to emphasize your relevant qualifications. During the interview, provide specific examples that demonstrate your abilities in:

- Steel shot production and quality control techniques

- Machine operation and maintenance

- Problem-solving and troubleshooting

- Safety and compliance knowledge

3. Practice Answering Common Interview Questions

Prepare for common interview questions that may be asked to assess your technical skills, problem-solving abilities, and work ethic. Practice answering them in a clear and concise manner, providing specific examples whenever possible.

- Tell me about your experience in operating steel shot heading machines.

- Describe a situation where you successfully resolved a production issue.

- How do you ensure the quality and consistency of steel shot products?

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your interest in the position and the company. Prepare a list of questions related to the job responsibilities, the company’s business strategy, and the potential for career growth.

- What are the key challenges facing the steel shot industry?

- How does the company plan to stay competitive in the global market?

- What opportunities are there for professional development within the company?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive for the interview on time. Be polite, respectful, and maintain a positive attitude throughout the interview process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steel Shot Header Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steel Shot Header Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.