Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hot Mill Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hot Mill Operator so you can tailor your answers to impress potential employers.

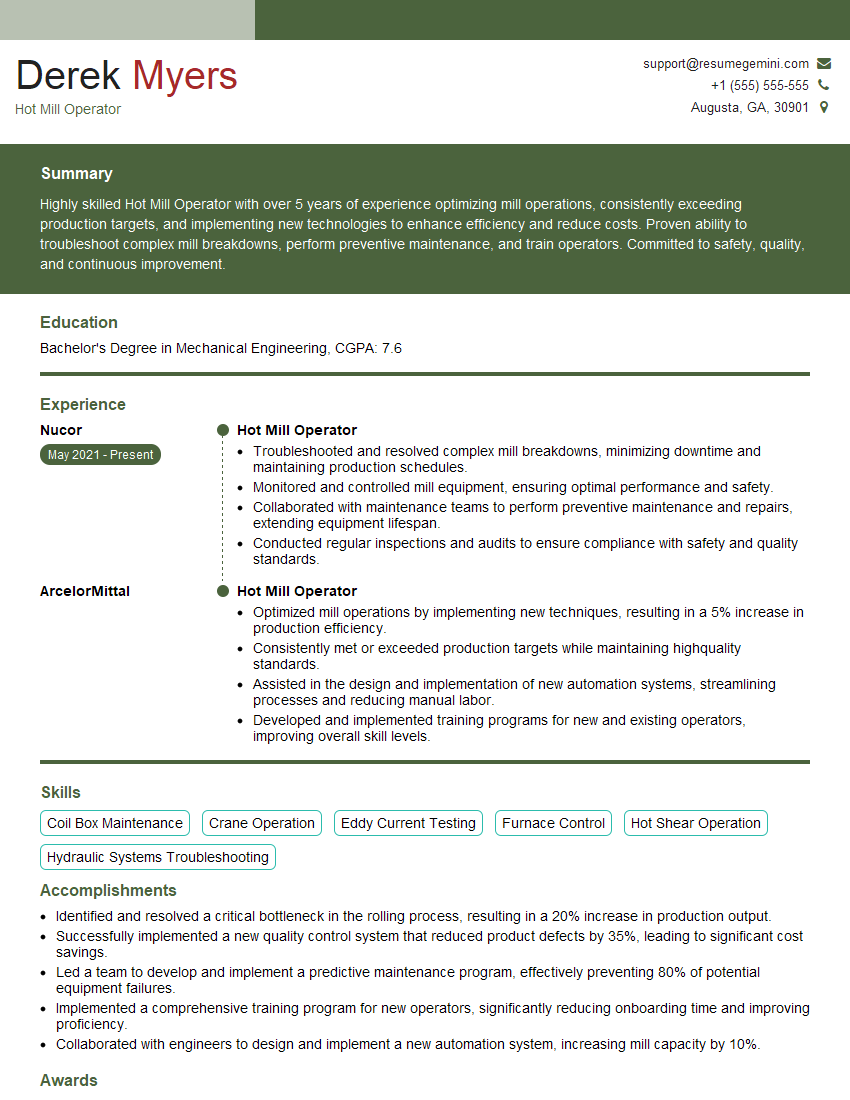

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hot Mill Operator

1. What are the key responsibilities of a Hot Mill Operator?

As a Hot Mill Operator, my primary responsibilities would include:

- Operating and monitoring the hot mill equipment, including furnaces, rolling mills, and cooling systems.

- Ensuring the mill operates efficiently and safely, meeting production targets and quality standards.

2. Describe the process of hot rolling steel.

Heating and Conditioning

- Steel slabs are heated in a furnace to a specific temperature, typically around 2300°F (1260°C).

- The heated slabs are then descaled to remove surface impurities.

Rolling

- The slabs are passed through a series of rolling mills, which gradually reduce their thickness and width.

- The rolling process can be divided into roughing and finishing stages, with each stage using different mill configurations.

Cooling

- After rolling, the hot steel is cooled rapidly using water or air jets.

- Rapid cooling helps to achieve the desired mechanical properties and prevent the formation of unwanted phases.

3. What are the different types of rolling mills used in hot rolling?

There are several types of rolling mills used in hot rolling, including:

- Reversing mills: These mills have rolls that rotate in both directions, allowing the material to be passed back and forth.

- Continuous mills: These mills have multiple stands of rolls arranged in a continuous line, allowing the material to flow through the mill without stopping.

- Universal mills: These mills have rolls that can be tilted to different angles, allowing for the production of a wide range of shapes.

4. How do you control the temperature of the steel during hot rolling?

Controlling the temperature of the steel during hot rolling is crucial to achieve the desired properties and prevent defects. I would use a combination of methods, including:

- Furnace temperature control: Monitoring and adjusting the temperature of the furnace to ensure it meets the required heating temperature.

- Water cooling: Using water jets to cool the steel after rolling to achieve the desired cooling rate.

- Air cooling: Using air jets to cool the steel after rolling, particularly when a slower cooling rate is desired.

5. What are the potential defects that can occur during hot rolling and how do you prevent them?

Common defects that can occur during hot rolling include:

- Edge cracks: Caused by excessive rolling force or improper cooling.

- Centerline cracks: Caused by excessive internal stresses or material defects.

- Surface defects: Such as pits, scabs, and scale, caused by impurities or improper surface preparation.

Prevention measures include:

- Proper heating and rolling practices.

- Meticulous surface preparation.

- Regular equipment maintenance.

6. How do you ensure the safety of yourself and others while operating a hot mill?

Safety is paramount in hot mill operations. I would adhere to strict safety protocols, including:

- Wearing appropriate personal protective equipment (PPE), such as heat-resistant clothing, gloves, and safety glasses.

- Maintaining a clean and organized work area.

- Following proper lockout/tagout procedures when performing maintenance or repairs.

7. How do you handle breakdowns or equipment malfunctions in the hot mill?

In the event of a breakdown or equipment malfunction, I would follow established procedures to ensure safety and minimize downtime:

- Immediately shut down the affected equipment and report the issue to the supervisor.

- Identify and isolate the source of the problem.

- If possible, attempt to troubleshoot and repair the issue while adhering to safety guidelines.

8. How do you coordinate with other departments, such as maintenance and quality control, to ensure smooth mill operations?

Effective coordination is essential for smooth mill operations. I would:

- Communicate regularly with maintenance personnel to schedule preventive maintenance and promptly address equipment issues.

- Work closely with quality control to monitor the quality of the finished product and ensure compliance with specifications.

- Maintain open lines of communication to resolve any issues or challenges that may arise.

9. How do you stay updated on the latest developments and best practices in hot mill operations?

To stay abreast of industry advancements, I would:

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Consult with experts and vendors in the field.

- Seek opportunities for training and professional development.

10. What are your strengths and weaknesses as a Hot Mill Operator?

My strengths include:

- Strong knowledge of hot rolling processes and equipment.

- Experience in operating and maintaining hot mills, ensuring optimal performance.

- Excellent problem-solving and troubleshooting skills.

Areas for improvement:

- Limited experience in working with specific types of steel alloys.

- Seeking to further enhance my knowledge in quality control techniques and defect analysis.

I am committed to continuous learning and development to address these areas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hot Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hot Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hot Mill Operator is a skilled professional responsible for the safe and efficient operation of hot rolling mills, which convert steel slabs into flat or long products. The key job responsibilities of a Hot Mill Operator include:

1. Operating and Maintaining Rolling Mill Equipment

Operate and maintain hot rolling mills, including furnaces, rolling stands, and ancillary equipment.

- Monitor and adjust mill settings to produce steel products within specifications.

- Perform maintenance and repairs on rolling mill equipment to ensure smooth operation.

2. Control and Monitor Rolling Process

Control and monitor the rolling process to ensure product quality and safety.

- Control mill speed, temperature, and tension to produce products with desired properties.

- Monitor process parameters such as roll gap, elongation, and cooling rates.

3. Quality Control and Inspection

Perform quality control inspections on steel products to ensure they meet specifications.

- Inspect products for defects such as cracks, surface imperfections, and dimensional inaccuracies.

- Record and report quality data to maintain product traceability and improve processes.

4. Safety and Environmental Compliance

Adhere to safety and environmental regulations and follow established procedures.

- Operate equipment safely and follow all safety protocols.

- Monitor environmental emissions and take measures to minimize the environmental impact.

Interview Tips

To prepare for an interview for a Hot Mill Operator position effectively, consider the following tips:

1. Research the Company and Position

Gather information about the company, its products, and the specific requirements of the Hot Mill Operator position.

- Visit the company website and review industry publications.

- Identify the key skills and experiences required for the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly relate to the responsibilities of a Hot Mill Operator.

- Provide specific examples of your experience in operating and maintaining rolling mills.

- Quantify your accomplishments to demonstrate your impact on production and quality.

3. Demonstrate Safety and Quality Consciousness

Stress your commitment to safety and quality.

- Describe your understanding of safety protocols and industry regulations.

- Provide examples of your involvement in quality control initiatives.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to hot rolling mill operations.

- Review the basics of metallurgy and metalworking.

- Familiarize yourself with the different types of hot rolling mills and their functions.

5. Practice Your Answers

Practice answering common interview questions to build confidence and clarity.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Consider preparing specific examples for questions related to safety, quality, and problem-solving.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hot Mill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hot Mill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.