Are you gearing up for a career in Mill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

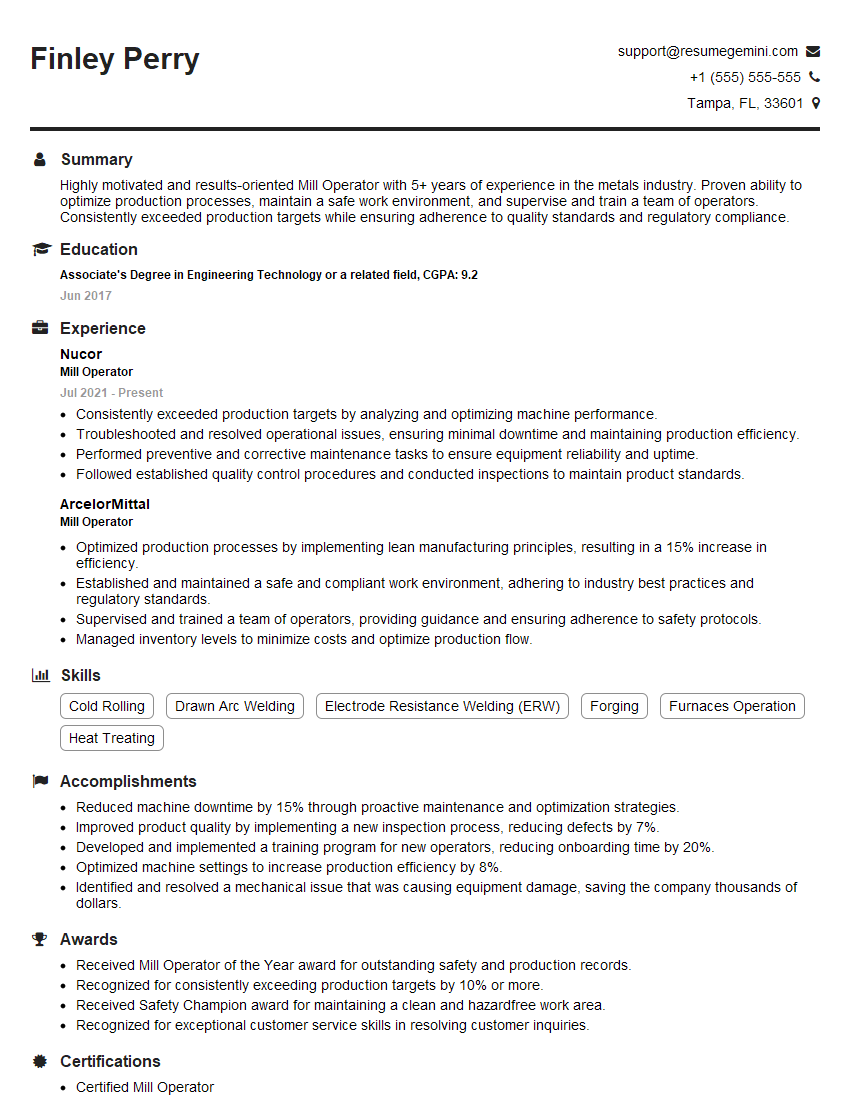

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Operator

1. Explain the role of a Mill Operator in a manufacturing plant?

As a Mill Operator, my primary responsibility is to operate and maintain milling machines to grind, crush, or pulverize raw materials or finished products. My duties include:

- Setting up and adjusting milling equipment to meet production requirements

- Monitoring the milling process to ensure efficient operation and product quality

- Making necessary adjustments to equipment to optimize performance

- Ensuring adherence to safety regulations and maintaining a clean and organized work area

2. What types of milling machines have you operated, and what are their key features?

Ball Mills

- Used for grinding materials into fine particles

- Consist of a rotating cylindrical shell filled with grinding balls

- Can be wet or dry

Hammer Mills

- Used for crushing or pulverizing materials

- Consist of a rotating shaft with hammers attached

- Produce a coarser grind than ball mills

3. Describe the process of setting up and adjusting a milling machine?

Setting up and adjusting a milling machine involves the following steps:

- Inspecting the machine and its components for any damage or wear

- Loading the machine with the appropriate grinding media and materials

- Adjusting the rotation speed, feed rate, and other parameters according to specifications

- Running a trial run to ensure optimal performance and product quality

4. How do you ensure the quality and consistency of milled products?

I ensure the quality and consistency of milled products through the following measures:

- Following established procedures and specifications for the milling process

- Monitoring the milling process and making adjustments as needed

- Conducting regular inspections of the final product to verify compliance with quality standards

- Maintaining accurate records of production parameters and product quality

5. What are the key safety precautions to observe when operating milling machines?

When operating milling machines, I adhere to the following key safety precautions:

- Wearing appropriate personal protective equipment (PPE), such as earplugs, goggles, and gloves

- Ensuring that the machine is properly grounded and guarded

- Inspecting the equipment for any defects or damage before operation

- Keeping hands and other body parts clear of moving machinery

- Following lockout/tagout procedures when servicing or repairing the machine

6. Describe the importance of preventative maintenance for milling machines?

Preventative maintenance for milling machines is crucial because it helps prevent breakdowns, extends the equipment’s lifespan, and ensures optimal performance. It involves:

- Regularly inspecting and cleaning the machine

- Lubricating moving parts

- Replacing worn or damaged components

- Conducting vibration analysis to identify potential issues

- Following manufacturer’s maintenance guidelines

7. How do you troubleshoot and resolve common problems encountered in milling operations?

Troubleshooting and resolving common problems in milling operations requires a methodical approach:

Identifying the problem

- Observing the machine’s behavior and error messages

- Consulting technical documentation and manuals

Investigating the cause

- Checking for loose connections, damaged components, or incorrect settings

- Analyzing process parameters and product quality

Implementing a solution

- Repairing or replacing faulty components

- Adjusting process parameters

- Re-calibrating the machine

8. Explain the importance of communication and teamwork in a milling environment?

Effective communication and teamwork are essential in a milling environment for:

- Coordinating production schedules and ensuring smooth operation

- Exchanging information about machine performance and product quality

- Identifying and resolving problems promptly

- Maintaining a safe and collaborative work environment

9. How do you prioritize and manage multiple tasks in a busy milling operation?

I prioritize and manage multiple tasks in a busy milling operation using the following strategies:

- Setting clear priorities based on production schedules and deadlines

- Breaking down large tasks into smaller, manageable steps

- Delegating tasks to team members when necessary

- Using tools such as checklists and work orders to track progress

- Communicating regularly with supervisors and colleagues to stay informed about changing priorities

10. Describe your experience in optimizing milling processes to improve efficiency and productivity?

In my previous role, I implemented several successful initiatives to optimize milling processes and enhance productivity:

Upgrading milling equipment

- Installed new ball mills with advanced grinding technology

- Replaced hammer mills with more efficient models

Optimizing process parameters

- Adjusted rotation speeds and feed rates to maximize grinding efficiency

- Implemented a preventative maintenance program to reduce downtime

Improving operator training

- Provided comprehensive training on best practices and troubleshooting techniques

- Established a system for continuous improvement and knowledge sharing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mill Operators are responsible for overseeing the daily operations of a mill, ensuring that production quotas are met and that the mill runs smoothly and efficiently.

1. Production and Quality Control

Mill Operators are responsible for ensuring that the mill produces high-quality products. This includes monitoring the production process, making adjustments to the machinery, and conducting quality control checks.

- Monitor production lines to ensure that products meet specifications.

- Conduct quality control checks on products to identify and correct defects.

2. Equipment Maintenance and Repair

Mill Operators are also responsible for maintaining and repairing the equipment used in the mill. This includes inspecting equipment, identifying problems, and making repairs.

- Inspect and maintain equipment to ensure it is in good working order.

- Identify and fix equipment problems to minimize downtime.

3. Health and Safety

Mill Operators are responsible for ensuring that the mill is a safe environment for workers. This includes enforcing safety regulations, conducting safety inspections, and providing safety training.

- Enforce safety regulations to ensure a safe work environment.

- Conduct safety inspections to identify and eliminate potential hazards.

4. Other Responsibilities

Mill Operators may also be responsible for performing other tasks, such as:

- Training new employees.

- Supervising other employees.

- Preparing reports on the mill’s operations.

- Coordinating with other departments.

Interview Tips

Preparing for an interview can be daunting, but there are steps you can take to increase your chances of success. Here are a few tips to help you ace your Mill Operator interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and the role you would be playing.

- Visit the company’s website to learn about its history, products, and services.

- Read industry news and articles to learn about the latest trends and technologies.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you may be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

Take some time to prepare your answers to these questions so that you can deliver them confidently and concisely.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, or even a few minutes early.

- Dress in a suit or business casual attire.

- Be well-groomed and make sure your clothes are clean and pressed.

- Arrive at the interview venue a few minutes early to give yourself time to relax and collect your thoughts.

4. Be Yourself and Be Confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and upfront about your skills and experience, and be confident in your abilities.

- Be genuine and authentic.

- Make eye contact with the interviewer and speak clearly and confidently.

- Don’t be afraid to ask questions and show that you are interested in the position.

Next Step:

Now that you’re armed with the knowledge of Mill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini