Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Milling/Polishing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

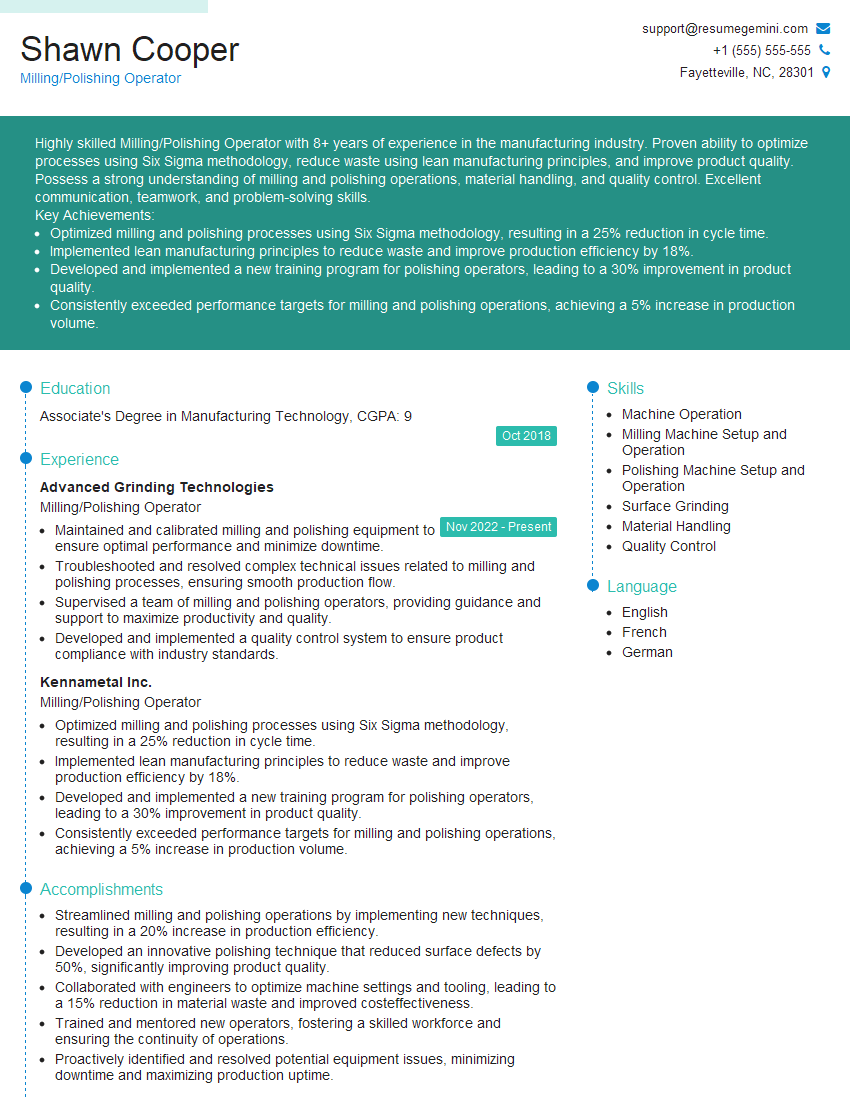

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Milling/Polishing Operator

1. Explain the different types of milling cutters used in the industry and their applications?

There are various types of milling cutters used in the industry, each designed for specific applications. Here are a few common types and their uses:

- End mills: These are cylindrical cutters with teeth on the end face and can be used for a wide range of operations, including facing, slotting, and contouring.

- Ball nose end mills: These cutters have a spherical cutting edge and are ideal for creating curved surfaces and intricate details.

- Face mills: These large-diameter cutters have multiple teeth on the periphery and are used for surfacing flat surfaces.

- Shell mills: These cutters have a cylindrical body with teeth on the circumference and are used for milling deep slots and pockets.

- Slab mills: These thin, rectangular cutters are used for creating flat surfaces and cutting slots.

2. Describe the process of setting up and operating a milling machine?

Workholding:

- Select the appropriate workholding device (vise, chuck, or fixture) based on the workpiece size and shape.

- Securely mount the workpiece in the workholding device.

Machine setup:

- Choose the correct milling cutter for the desired operation.

- Mount the cutter in the spindle and tighten it securely.

- Set the spindle speed and feed rate according to the workpiece material and cutter size.

- Adjust the table position and depth of cut.

Operation:

- Start the machine and engage the cutter with the workpiece.

- Monitor the cutting process and make adjustments as needed.

- Once the desired cut is achieved, retract the cutter and stop the machine.

3. How do you maintain and troubleshoot milling machines?

Regular maintenance and troubleshooting are crucial to keep milling machines operating efficiently. Here are some common maintenance and troubleshooting tips:

- Maintenance:

- Clean and lubricate the machine regularly.

- Inspect the spindle and bearings for wear or damage.

- Check the cutting tools for sharpness and replace them when necessary.

- Troubleshooting:

- If the cutter is vibrating excessively, check for proper mounting and balance.

- If the workpiece is not being cut properly, check the tool settings, spindle speed, and feed rate.

- If the machine is making unusual noises, stop the operation and inspect for any damage or loose components.

4. What are the safety precautions to be taken while operating a milling machine?

Safety is paramount when operating a milling machine. Here are some essential safety precautions:

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Ensure that the machine is properly grounded to prevent electrical shock.

- Keep the work area clean and free of debris.

- Securely fasten the workpiece to prevent it from moving during operation.

- Keep hands and loose clothing away from moving parts.

- Never attempt to stop the machine with your hands.

5. Explain the role of coolants in milling operations?

Coolants play a vital role in milling operations by providing lubrication and removing heat from the cutting zone. Here are the benefits of using coolants:

- Reduced friction between the cutter and workpiece, leading to longer tool life.

- Improved surface finish on the workpiece due to reduced heat-induced distortion.

- Flushing away chips and debris from the cutting area, preventing tool clogging.

- Cooling the workpiece and preventing thermal damage.

6. What are the different materials used in the polishing process and their applications?

Various materials are used in polishing, each with specific characteristics and applications:

- Abrasives: These include materials like silicon carbide, aluminum oxide, and diamond, used for removing material and creating a smooth surface.

- Polishing pads: Made from materials like felt, foam, or cloth, these pads hold the abrasive and conform to the workpiece surface.

- Liquids and compounds: These are applied to the polishing pad or workpiece to lubricate the process and enhance the polishing effect.

7. Describe the techniques used for polishing different types of surfaces?

Polishing techniques vary depending on the surface type and desired finish:

Metal surfaces:

- Abrasive belt grinding: Uses abrasive belts to remove material and achieve a smooth finish.

- Buffing: Employs rotating buffs with abrasive compounds to create a high-gloss finish.

Plastic surfaces:

- Flame polishing: Exposes the surface to a controlled flame to melt and smooth the material.

- Mechanical polishing: Uses abrasive pads or wheels to remove scratches and create a glossy finish.

8. How do you determine the correct grit size for polishing?

Selecting the appropriate grit size is crucial for effective polishing:

- Coarse grit: Used for removing heavy scratches and material, creating a rougher surface.

- Medium grit: Refines the surface after coarse grit, removing smaller scratches.

- Fine grit: Produces a smooth, polished finish, removing fine scratches and imperfections.

Factors to consider:

- Workpiece material

- Desired surface finish

- Polishing technique used

9. What are the common defects that can occur during the polishing process?

Several defects can arise during polishing:

- Scratches: Caused by abrasive particles or improper polishing techniques.

- Haze: A milky or cloudy appearance on the surface due to improper cleaning or oxidation.

- Burnishing: A dull or matte finish resulting from excessive heat or pressure during polishing.

- Orange peel: A rough, textured surface caused by uneven polishing or improper abrasive selection.

- Corrosion: Can occur if the polished surface is not properly protected from environmental factors.

10. How do you maintain and calibrate polishing equipment?

Regular maintenance and calibration ensure optimal performance of polishing equipment:

Maintenance:

- Clean and inspect equipment regularly.

- Replace worn or damaged components, such as polishing pads and belts.

- Lubricate moving parts as per manufacturer’s instructions.

Calibration:

- Use a surface profiler or other measuring device to verify the accuracy of polishing results.

- Adjust equipment settings, such as spindle speed and pressure, to meet desired specifications.

- Regularly check and calibrate the equipment to maintain consistent performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Milling/Polishing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Milling/Polishing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Milling/Polishing Operators are responsible for operating and maintaining milling and polishing equipment to produce high-quality finished products. Their key responsibilities include:

1. Equipment Operation

- Operate milling and polishing machines to remove excess material, create smooth surfaces, and achieve desired finishes.

- Calibrate and adjust equipment settings to ensure optimal performance and precision.

- Monitor machine operation to detect any issues and take corrective action.

2. Material Handling

- Prepare and load raw materials into milling and polishing equipment.

- Inspect materials to ensure they meet specifications and quality standards.

- Unload finished products from equipment and prepare them for further processing.

3. Quality Control

- Inspect finished products to ensure they meet specifications and customer requirements.

- Identify and correct defects or quality issues.

- Maintain quality records and documentation.

4. Maintenance and Troubleshooting

- Perform regular maintenance on milling and polishing equipment to prevent breakdowns.

- Troubleshoot and resolve equipment malfunctions or issues to minimize downtime.

- Keep equipment clean and organized for efficient operation.

Interview Tips

To ace an interview for a Milling/Polishing Operator position, follow these tips:

1. Research the Company and Role

- Learn about the company’s history, products, and values.

- Thoroughly review the job description and identify key responsibilities.

2. Practice Common Interview Questions

- Prepare answers to typical interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Practice your answers to demonstrate your skills, experience, and enthusiasm.

3. Highlight Relevant Skills and Experience

- Emphasize your previous experience in operating and maintaining milling and polishing equipment.

- Quantify your accomplishments using specific metrics to showcase your impact.

4. Show Your Attention to Detail and Precision

- Discuss your commitment to quality control and attention to detail.

- Provide examples of how you ensure the production of high-quality finished products.

5. Be Prepared for Technical Questions

- Review milling and polishing techniques, equipment types, and safety protocols.

- Be ready to discuss your knowledge of different materials and their behavior during the milling and polishing process.

6. Ask Thoughtful Questions

- Prepare insightful questions to ask the interviewer about the company, the role, and the industry.

- Asking questions demonstrates your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Milling/Polishing Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.