Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mill Control Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

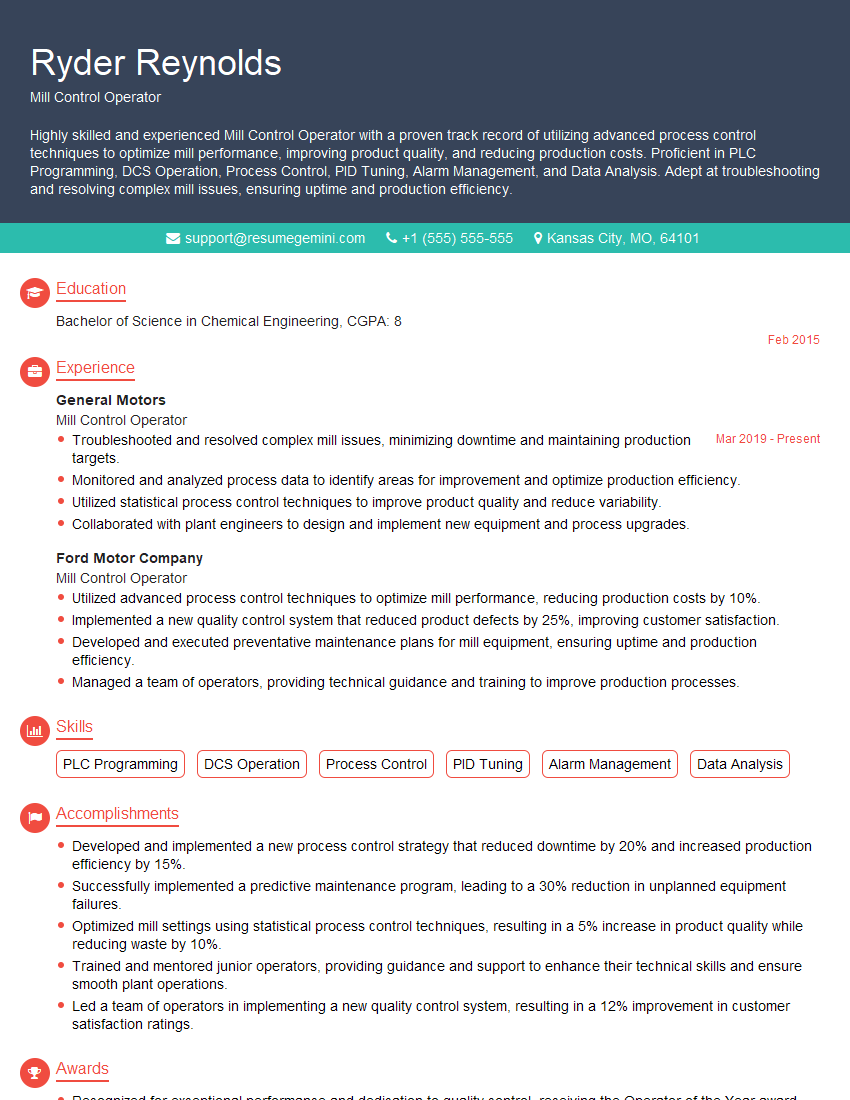

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mill Control Operator

1. How do you monitor and control the grinding process to ensure optimal performance?

To monitor and control the grinding process for optimal performance, I follow a comprehensive approach that involves:

- Monitoring key process parameters: I closely monitor parameters such as feed rate, product size distribution, and power consumption to identify any deviations from desired values.

- Adjusting mill settings: Based on the monitored data, I make necessary adjustments to mill settings, such as speed, feed rate, and classifier settings, to optimize product quality and minimize energy consumption.

- Maintaining equipment: I conduct regular inspections and maintenance of grinding equipment to ensure its proper functioning and prevent breakdowns that could affect process efficiency.

- Process optimization: I continuously analyze process data and explore opportunities for improvement by implementing process modifications or introducing new technologies to enhance grinding efficiency.

2. Describe your experience in using statistical process control (SPC) techniques in a mill control setting.

Benefits of SPC

- Improved product quality

- Reduced process variability

- Early detection of process shifts

Implementation of SPC

- Data collection and analysis

- Control chart development

- Process monitoring and adjustment

Case Study

In my previous role, I successfully implemented SPC in a ball mill operation. By monitoring key process variables, we identified a pattern of variation that was previously undetected. Through root cause analysis, we discovered that the variability was caused by inconsistent feed material properties. By implementing corrective actions to ensure consistent feed, we significantly reduced product size variation and improved overall process stability.

3. How do you handle situations where the mill is experiencing unexpected downtime?

- Safety first: Prioritize the safety of personnel and the equipment by following established safety protocols.

- Rapid troubleshooting: Conduct a thorough investigation to identify the root cause of the downtime, utilizing tools such as fault trees and diagnostic techniques.

- Repair or replacement: Based on the identified root cause, determine whether repairs or equipment replacement is necessary to restore operations.

- Communication: Keep stakeholders informed about the situation, estimated downtime, and any alternative measures being implemented to minimize production loss.

- Post-mortem analysis: Once the mill is back in operation, conduct a post-mortem analysis to identify any systemic issues or areas for improvement to prevent similar incidents in the future.

4. Can you describe the role of automation in modern mill control systems?

- Improved process control: Automation allows for precise control of process parameters, resulting in consistent product quality and reduced variability.

- Increased efficiency: Automated systems can perform repetitive tasks more efficiently than manual operations, freeing up operators for more complex tasks.

- Enhanced safety: Automation reduces the need for human intervention in hazardous areas, minimizing the risk of accidents.

- Data collection and analysis: Automated systems collect vast amounts of data that can be analyzed to identify trends, predict failures, and optimize processes.

- Remote monitoring: Automation enables remote monitoring of mill operations, allowing for proactive maintenance and troubleshooting from anywhere.

5. How do you ensure the accuracy and calibration of mill control instrumentation?

- Regular calibration: Establish a schedule for regular calibration of all critical instruments using certified standards and procedures.

- Verification: Conduct periodic verification checks to ensure instruments are within acceptable accuracy ranges.

- Documentation: Maintain detailed records of calibration and verification activities, including dates, results, and any adjustments made.

- Training: Provide training to operators on proper instrument handling, calibration techniques, and troubleshooting.

- Collaboration with vendors: Engage with instrument vendors for technical support, maintenance recommendations, and software updates.

6. Describe your experience in managing multiple mills within a complex production environment.

- Production coordination: Coordinate production schedules and ensure seamless transitions between mills to meet customer demand.

- Process optimization: Monitor and optimize the performance of each mill to maximize overall production efficiency.

- Resource allocation: Allocate resources, such as operators, maintenance personnel, and raw materials, to ensure optimal utilization and minimize downtime.

- Communication and collaboration: Communicate effectively with mill operators, supervisors, and other stakeholders to ensure smooth coordination and problem-solving.

- Problem-solving: Troubleshoot and resolve production issues, identifying root causes and implementing corrective actions.

7. Explain your understanding of the relationship between mill throughput and product quality.

- Direct relationship: Increased throughput generally leads to higher production rates, but may compromise product quality if the mill is not operated within its optimal parameters.

- Optimal throughput: Determining the optimal throughput for a specific mill and product is crucial to achieve a balance between productivity and quality.

- Monitoring and adjustment: Continuously monitor throughput rates and product quality to make necessary adjustments to mill settings and processes to maintain desired quality standards.

8. How do you stay up-to-date with advancements in mill control technology?

- Industry conferences and trade shows: Attend industry events to learn about new technologies, research findings, and best practices.

- Technical journals and publications: Subscribe to industry-specific journals and publications to stay informed about technological advancements.

- Online forums and discussion groups: Participate in online forums and discussion groups to engage with other professionals and exchange knowledge.

- Collaboration with vendors: Maintain relationships with equipment vendors to gain insights into latest technological developments and receive technical support.

- Training and workshops: Attend training sessions and workshops offered by industry experts to enhance technical skills and knowledge.

9. Describe your approach to ensuring environmental compliance in mill operations.

- Compliance regulations: Understand and adhere to all applicable environmental compliance regulations and standards.

- Emission control: Implement effective emission control measures to minimize air and water pollution, such as dust collectors and wastewater treatment systems.

- Waste management: Establish proper waste management practices to dispose of hazardous and non-hazardous waste in an environmentally responsible manner.

- Energy efficiency: Optimize mill operations to minimize energy consumption and reduce greenhouse gas emissions.

- Environmental monitoring: Conduct regular environmental monitoring to ensure compliance and identify any potential environmental risks.

10. Can you provide an example of a time when you successfully resolved a complex mill control issue?

Problem description

Describe a specific and challenging mill control issue that you encountered.

Troubleshooting process

- List the steps you took to troubleshoot the issue, including data analysis, equipment inspection, and consultation with experts.

Solution implementation

- Explain the solution you identified and implemented to resolve the issue.

Results achieved

- Quantify the improvements or benefits achieved as a result of your intervention.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mill Control Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mill Control Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Mill Control Operator is responsible for ensuring the smooth and efficient operation of the production mill, operating and monitoring the mill’smachinery,equipment, and processes, while adhering to established quality standards and safety procedures.

1. Equipment and Process Monitoring

Observes and monitors the mill’s machinery and processes, including conveyors, crushers, grinders, and other equipment to ensure they are functioning properly.

- Detects and resolves any operational issues promptly, minimizing downtime and production loss.

- Maintains accurate records of equipment performance and maintenance schedules.

2. Quality Control

Monitors the quality of the mill’s products throughout the production process, ensuring consistency and adherence to established specifications.

- Conducts regular checks on product quality using appropriate testing methods and equipment.

- Adjusts process parameters and equipment settings to optimize product quality.

3. Process Optimization

Continuously evaluates and improves mill processes to enhance efficiency and productivity.

- Identifies areas for process improvement and implements changes as necessary.

- Collaborates with maintenance and engineering teams to optimize equipment and processes.

4. Safety Compliance

Maintains a safe and compliant work environment in the mill.

- Adheres to established safety protocols and procedures.

- Conducts regular safety inspections and reports any hazards or potential risks.

Interview Tips

Preparing for a Mill Control Operator interview requires a combination of technical knowledge and soft skills. Here are some key tips to help candidates ace their interview:

1. Research the Company and Role

Familiarize yourself with the company’s operations, industry standing, and the specific responsibilities of the Mill Control Operator role. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Relevant Experience

Emphasize your experience in operating and monitoring similar equipment or processes in a mill environment. Quantify your accomplishments and provide specific examples of how you have contributed to process optimization and quality control.

3. Demonstrate Problem-Solving Skills

Be prepared to discuss your problem-solving abilities and how you handle unexpected situations. Share examples of how you have identified and resolved production issues while maintaining safety and efficiency.

4. Show Commitment to Safety

Highlight your commitment to maintaining a safe work environment. Describe your knowledge of safety protocols and your proactive approach to identifying and mitigating potential hazards.

5. Practice Common Interview Questions

Prepare for common interview questions such as “Tell us about your experience in mill operations?” and “What are your strengths and weaknesses as a Mill Control Operator?” Practice your answers to deliver clear, concise, and confident responses.

6. Ask Questions

At the end of the interview, ask thoughtful questions that show your interest in the company and the role. This demonstrates your engagement and enthusiasm for the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mill Control Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mill Control Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.