Are you gearing up for a career in Roll Forming Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roll Forming Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

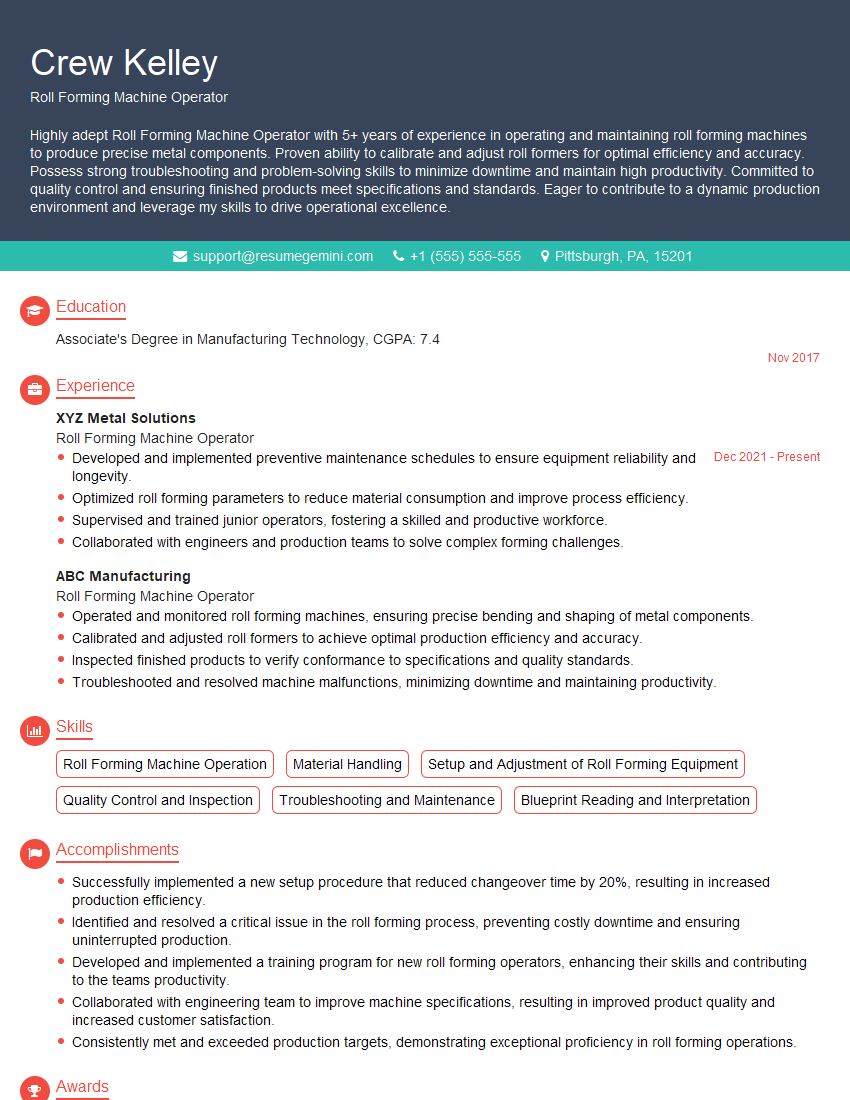

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roll Forming Machine Operator

1. What are the main responsibilities of a Roll Forming Machine Operator?

- Operate and maintain roll forming machines to produce metal components with specific shapes and dimensions.

- Set up and adjust machines based on engineering drawings and specifications.

- Monitor machine operation and make adjustments as needed to ensure quality and productivity.

- Inspect finished products for defects and deviations from specifications.

- Troubleshoot and resolve any technical issues that arise during the production process.

2. Describe the different types of roll forming machines and their applications.

Types of Roll Forming Machines:

- Single-pass machines: Produce simple shapes in a single pass through the rolls.

- Multi-pass machines: Create complex shapes by passing the metal through multiple sets of rolls.

- Hydraulic machines: Use hydraulic pressure to apply force to the rolls.

- Mechanical machines: Use gears and shafts to transmit power to the rolls.

Applications:

- Automotive industry: Producing car frames, bumpers, and other components.

- Construction industry: Creating roofing panels, siding, and structural elements.

- Appliance industry: Manufacturing components for refrigerators, ovens, and other appliances.

- Aerospace industry: Producing aircraft parts such as wings and fuselage sections.

3. What are the key factors that determine the quality of roll-formed products?

- Machine accuracy: Precision of the rolls and alignment of the machine components.

- Material properties: Thickness, strength, and ductility of the metal being formed.

- Roll design: Shape and profile of the rolls to achieve the desired product dimensions.

- Process parameters: Speed, temperature, and lubrication during the forming process.

- Operator skill: Experience and attention to detail in setting up and operating the machine.

4. How do you troubleshoot common problems that occur during roll forming?

- Poor quality of finished products: Check for misaligned rolls, defective material, or improper process parameters.

- Roll wear: Inspect rolls for damage or excessive wear, and replace or repair as necessary.

- Machine breakdowns: Diagnose electrical or mechanical issues, and contact maintenance personnel for repairs.

- Material jamming: Clear any obstructions in the machine and adjust the feed rate or lubrication system.

- Safety concerns: Ensure proper machine guarding and follow all safety protocols.

5. What is the importance of maintenance and calibration in roll forming operations?

- Extended machine life: Proper maintenance prevents premature wear and tear, prolonging the machine’s lifespan.

- Improved product quality: Regular calibration ensures precise roll alignment and consistency in product dimensions.

- Reduced downtime: Maintenance and calibration identify potential issues early on, preventing breakdowns and minimizing unplanned downtime.

- Increased safety: Well-maintained machines reduce the risk of accidents and injuries.

- Improved efficiency: Calibration optimizes the machine’s performance, reducing scrap and increasing production efficiency.

6. What are the different types of materials that can be used in roll forming?

7. How do you ensure that roll-formed products meet the required tolerances?

- Proper machine setup: Setting the machine to the correct dimensions and specifications.

- Regular calibration: Ensuring the machine maintains accuracy over time.

- In-process inspection: Monitoring the product during the forming process and making adjustments as necessary.

- Post-process inspection: Inspecting the finished product and verifying its compliance with specifications.

- Use of measuring tools: Relying on precision measuring equipment such as calipers and micrometers.

8. What are the safety precautions that must be taken when operating a roll forming machine?

- Wear proper personal protective equipment (PPE): Safety glasses, gloves, and hearing protection.

- Follow lockout/tagout procedures: Ensure the machine is de-energized and locked out before performing maintenance or repairs.

- Keep hands and loose clothing away from moving parts: Avoid entanglement hazards.

- Use proper lifting techniques: Be cautious when handling heavy materials or machine components.

- Be aware of pinch points: Identify potential areas where materials or fingers could get pinched.

9. What is the role of a programmable logic controller (PLC) in a roll forming operation?

- Machine control: Automating the sequence of operations and controlling machine functions.

- Process monitoring: Tracking production data and identifying process deviations.

- Data acquisition: Collecting data on machine performance, product quality, and process parameters.

- Fault detection: Diagnosing problems and triggering alarms to alert operators and maintenance personnel.

- Recipe management: Storing and retrieving production parameters for different product types.

10. How do you stay up to date with the latest advancements in roll forming technology?

- Attend industry trade shows and conferences: Engage with vendors and learn about new products and techniques.

- Read industry publications and technical journals: Stay informed about best practices and innovative technologies.

- Consult with equipment manufacturers: Seek information from experts about machine improvements and process optimizations.

- Participate in online forums and discussion groups: Share knowledge and exchange ideas with other professionals.

- Take training courses: Enhance skills and learn about new technologies through hands-on workshops or online courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roll Forming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roll Forming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roll Forming Machine Operators are responsible for the safe and efficient operation of roll forming machines, which are used to shape and form various metal products. Their key job responsibilities include:

1. Machine Setup and Operation

Setting up and operating roll forming machines according to specified instructions and blueprints

- Adjusting machine settings, including roll gap, speed, and tension

- Loading raw materials and monitoring the forming process

2. Quality Control and Inspection

Inspecting formed products to ensure they meet quality standards

- Measuring and checking dimensions, tolerances, and surface finish

- Identifying and correcting any defects or non-conformances

3. Maintenance and Troubleshooting

Performing routine maintenance tasks to keep machines in good working order

- Cleaning and lubricating machines

- Identifying and troubleshooting machine problems, and making necessary repairs or adjustments

4. Safety and Compliance

Following established safety procedures and regulations

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

Interview Tips

To prepare effectively for an interview for a Roll Forming Machine Operator position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Review the job description thoroughly to understand the specific requirements and expectations of the role.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles related to roll forming.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating roll forming machines and your knowledge of quality control procedures. Share specific examples of your experience in troubleshooting and resolving machine issues.

- Quantify your accomplishments whenever possible.

- Use action verbs and technical terms specific to the field.

3. Demonstrate Safety Awareness

Safety is paramount in manufacturing environments. Highlight your understanding of safety protocols and procedures, including the use of PPE and lockout/tagout practices.

- Share examples of how you have maintained a safe work environment.

- Emphasize your commitment to following safety regulations.

4. Ask Informed Questions

Asking thoughtful questions shows your interest in the position and company. Prepare questions related to the machine operation, quality standards, or the company’s growth plans.

- Avoid generic questions that can be easily answered from the job description.

- Tailor your questions to the specific company and industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roll Forming Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roll Forming Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.