Feeling lost in a sea of interview questions? Landed that dream interview for Rolls Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rolls Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

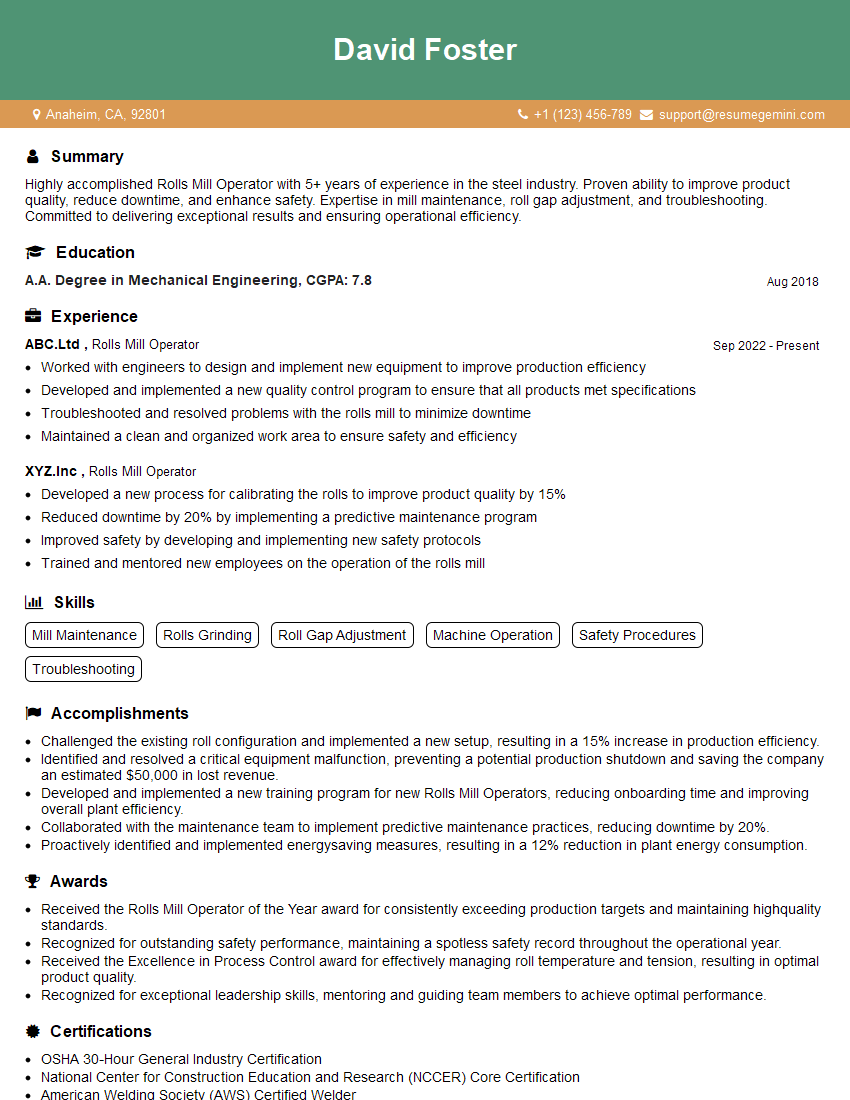

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rolls Mill Operator

1. What is the purpose of a Rolls Mill and how does it work?

- A Rolls Mill is a size reduction machine used in various industries, such as mining, cement, and pharmaceuticals.

- It consists of two heavy cylindrical rolls that rotate towards each other, crushing materials fed between them.

- The gap between the rolls determines the size of the crushed product.

2. What are the different types of Rolls Mills?

- Single Roll Crushers: Feature one rotating roll against a stationary plate.

- Double Roll Crushers: Utilize two counter-rotating rolls.

3. What are the key factors to consider when selecting a Rolls Mill?

- Feed size and required output size

- Material hardness and abrasiveness

- Throughput capacity

- Power consumption

- Maintenance and operating costs

4. What are the common maintenance tasks performed on Rolls Mills?

- Roll replacement

- Bearing lubrication

- Conveyor belt inspection

- Electrical and mechanical system checks

5. How do you ensure the efficiency of a Rolls Mill?

- Proper feed rate control

- Optimal roll gap setting

- Regular maintenance and lubrication

- Monitoring power consumption and throughput

- Employee training and adherence to best practices

6. How do you troubleshoot an undersized product issue in a Rolls Mill?

- Check the roll gap and adjust it accordingly

- Inspect the rolls for wear or damage

- Ensure the feed rate is consistent and not overloading the mill

- Verify the material hardness and abrasiveness

- Consult the manufacturer’s recommendations for the specific material being processed

7. What are the safety precautions to be taken when operating a Rolls Mill?

- Wear appropriate PPE (safety glasses, gloves, earplugs)

- Lock out/tag out the mill before any maintenance

- Follow proper lockout/tagout procedures

- Keep the work area clean and free of tripping hazards

- Never reach into the mill while it is running

8. What is your experience with Rolls Mill optimization and process improvement?

Describe specific initiatives you have implemented, such as:

- Optimizing feed rate and roll gap settings

- Implementing preventive maintenance programs

- Training operators on best practices

9. How do you stay up-to-date with the latest developments in Rolls Mill technology?

- Attend industry conferences and workshops

- Read technical journals and articles

- Consult with manufacturers and distributors

- Network with other Rolls Mill professionals

10. What differentiates you from other Rolls Mill Operators?

- Highlight your unique skills, experience, or certifications

- Emphasize your passion for the field and your commitment to continuous improvement

- Explain how your qualifications make you an ideal candidate for the position

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rolls Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rolls Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Rolls Mill Operator, you will be responsible for various critical tasks within the manufacturing process.

1. Operation and Maintenance

You will operate the rolls mill to mill materials, ensuring smooth and efficient production.

- Monitor mill settings and adjust as needed to meet production specifications.

- Perform routine maintenance and cleaning of the mill to maintain optimal performance.

2. Quality Control

You will be responsible for ensuring the quality of the milled materials.

- Conduct quality checks at various stages of the milling process.

- Identify and rectify any non-conformance with quality standards.

3. Production Records and Reports

You will maintain accurate records and reports related to mill operations.

- Record production data, including output, yield, and downtime.

- Prepare daily and weekly reports for management and production planning.

4. Safety and Environmental Compliance

You will adhere to safety and environmental regulations and procedures.

- Maintain a clean and safe work environment.

- Follow all safety protocols and use appropriate personal protective equipment.

Interview Preparation Tips

To ace your interview for a Rolls Mill Operator position, it’s crucial to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Role

Gather information about the company’s industry, products, and company culture. Read the job description carefully to understand the specific requirements and responsibilities.

- Visit the company’s website and social media pages.

- Network with people who work at the company, if possible.

2. Practice Common Interview Questions

Prepare answers to commonly asked interview questions, such as:

- Tell me about your experience with rolls mill operations.

- How do you ensure the quality of the milled materials?

- What safety procedures do you follow in a manufacturing environment?

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Quantify your accomplishments whenever possible.

- Provide specific examples of your ability to operate and maintain a rolls mill.

- Share your experience in quality control and record-keeping.

4. Demonstrate Your Safety Awareness

Safety is crucial in a manufacturing environment. Discuss your understanding of safety protocols and your commitment to maintaining a safe workplace.

- Highlight your knowledge of relevant regulations.

- Mention any safety training or certifications you have obtained.

5. Be Confident and Enthusiastic

Believe in yourself and your abilities. Show the interviewer that you are excited about the opportunity and eager to contribute to the team.

- Maintain eye contact and speak clearly and confidently.

- Be prepared to talk about your passion for manufacturing and your desire to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rolls Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!