Are you gearing up for an interview for a Skelp Processor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Skelp Processor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

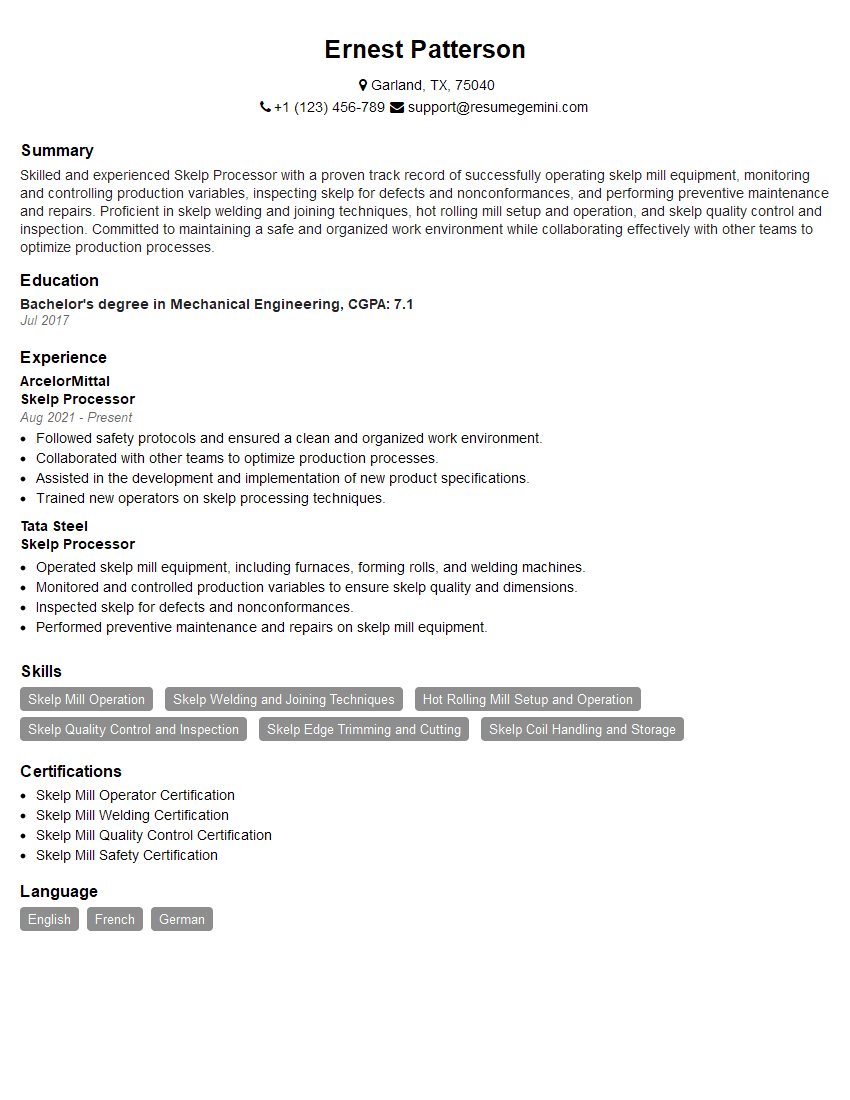

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skelp Processor

1. Explain the production process of skelp?

The production process of skelp involves the following steps:

- Steel billets are heated in a furnace to make them malleable.

- The heated billets are then rolled into a long, thin strip called a skelp.

- The skelp is then cut into the desired lengths and widths.

- The skelp is then further processed, such as by galvanizing or coating it with a protective layer.

2. What are the different types of skelp?

Flat-rolled skelp

- This is the most common type of skelp.

- It is used to make pipes and tubes.

Edge-rolled skelp

- This type of skelp has a raised edge on one side.

- It is used to make welded pipes.

3. What are the key properties of skelp?

The key properties of skelp include:

- Tensile strength

- Yield strength

- Elongation

- Surface finish

- Dimensional accuracy

4. What are the applications of skelp?

Skelp is used in a wide range of applications, including:

- Pipes and tubes

- Boilers

- Pressure vessels

- Automotive components

- Construction

5. What are the challenges in the production of skelp?

The challenges in the production of skelp include:

- Maintaining the desired properties of the skelp, such as tensile strength and surface finish.

- Controlling the production process to minimize defects.

- Meeting the customer’s specifications.

6. What is the role of a Skelp Processor?

The role of a Skelp Processor is to:

- Operate and maintain skelp processing equipment.

- Monitor the production process to ensure that the skelp meets the desired specifications.

- Troubleshoot and resolve any problems that may occur during the production process.

- Maintain a safe and clean work environment.

7. What are the skills and qualifications required to be a Skelp Processor?

The skills and qualifications required to be a Skelp Processor include:

- A high school diploma or equivalent.

- Experience operating and maintaining skelp processing equipment.

- Knowledge of the production process of skelp.

- Ability to read and interpret blueprints and technical drawings.

- Strong problem-solving skills.

- Good communication skills.

8. What is the work environment of a Skelp Processor?

Skelp Processors typically work in a factory setting.

- The work environment may be hot, noisy, and dusty.

- Skelp Processors may be required to work overtime or on weekends.

- Skelp Processors may be required to lift heavy objects.

9. What is the career outlook for Skelp Processors?

The career outlook for Skelp Processors is expected to be good.

- The demand for skelp is expected to grow as the construction and automotive industries expand.

- Skelp Processors with experience and skills are expected to be in high demand.

10. What are the salary expectations for Skelp Processors?

The salary expectations for Skelp Processors vary depending on their experience and skills.

- Entry-level Skelp Processors can expect to earn around $25,000 per year.

- Experienced Skelp Processors can expect to earn around $40,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skelp Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skelp Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Skelp Processor is a skilled individual responsible for operating and maintaining machines that manufacture skelp, a type of steel strip used in the production of pipes and tubes.

1. Machine Operation

Operate and maintain skelp processing machines, including rolling mills, slitters, and coilers.

- Adjust machine settings and parameters to achieve desired product specifications.

- Monitor and inspect processed skelp for defects and adherence to quality standards.

2. Process Control

Control and monitor the skelp processing line, ensuring efficient production and adherence to safety protocols.

- Manage raw material inventory and ensure smooth material flow through the production process.

- Identify and resolve production bottlenecks, optimizing machine performance and production rates.

3. Quality Assurance

Conduct regular quality checks on processed skelp, ensuring compliance with industry standards and customer specifications.

- Inspect skelp for surface defects, dimensional accuracy, and other quality parameters.

- Maintain quality records and provide feedback to relevant departments for continuous improvement.

4. Equipment Maintenance

Perform preventive maintenance and repairs on skelp processing machinery and equipment.

- Inspect and replace worn or damaged machine components, including bearings, gears, and electrical systems.

- Lubricate and adjust equipment as necessary to ensure optimal performance and extend machine life.

Interview Tips

Preparing for an interview for a Skelp Processor position requires thorough knowledge of the job responsibilities and industry-specific practices. Here are some tips to help you ace the interview.

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and industry presence. Research the specific role and its responsibilities. This knowledge will help you tailor your answers to the interviewer’s questions.

2. Showcase Your Technical Skills

Highlight your experience in operating and maintaining skelp processing machinery. Explain your understanding of the production process and how you ensure the quality of the final product.

3. Emphasize Problem-Solving Abilities

Share examples of how you have identified and resolved production issues. Discuss your approach to troubleshooting and improving machine performance.

4. Demonstrate Quality Consciousness

Explain your commitment to quality assurance and your understanding of industry standards. Describe your experience in conducting quality checks and maintaining quality records.

5. Highlight Safety Awareness

Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment. Discuss your experience in identifying and mitigating potential hazards.

6. Prepare Questions

Prepare thoughtful questions to ask the interviewer. This shows your interest in the company and the position and gives you a chance to gather additional information.

7. Dress Professionally

First impressions matter, so dress appropriately for the interview. A neat and professional appearance conveys respect and confidence.

8. Be Punctual

Punctuality is essential for any job interview. Plan your route and arrive on time to show that you value the interviewer’s time.

9. Maintain Eye Contact

Eye contact is a powerful communication tool that conveys confidence and engagement. Make eye contact with the interviewer during the conversation.

10. Practice Active Listening

Demonstrate active listening by paying attention to the interviewer’s questions and repeating back key points to ensure understanding.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Skelp Processor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!