Are you gearing up for an interview for a Temper Mill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Temper Mill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

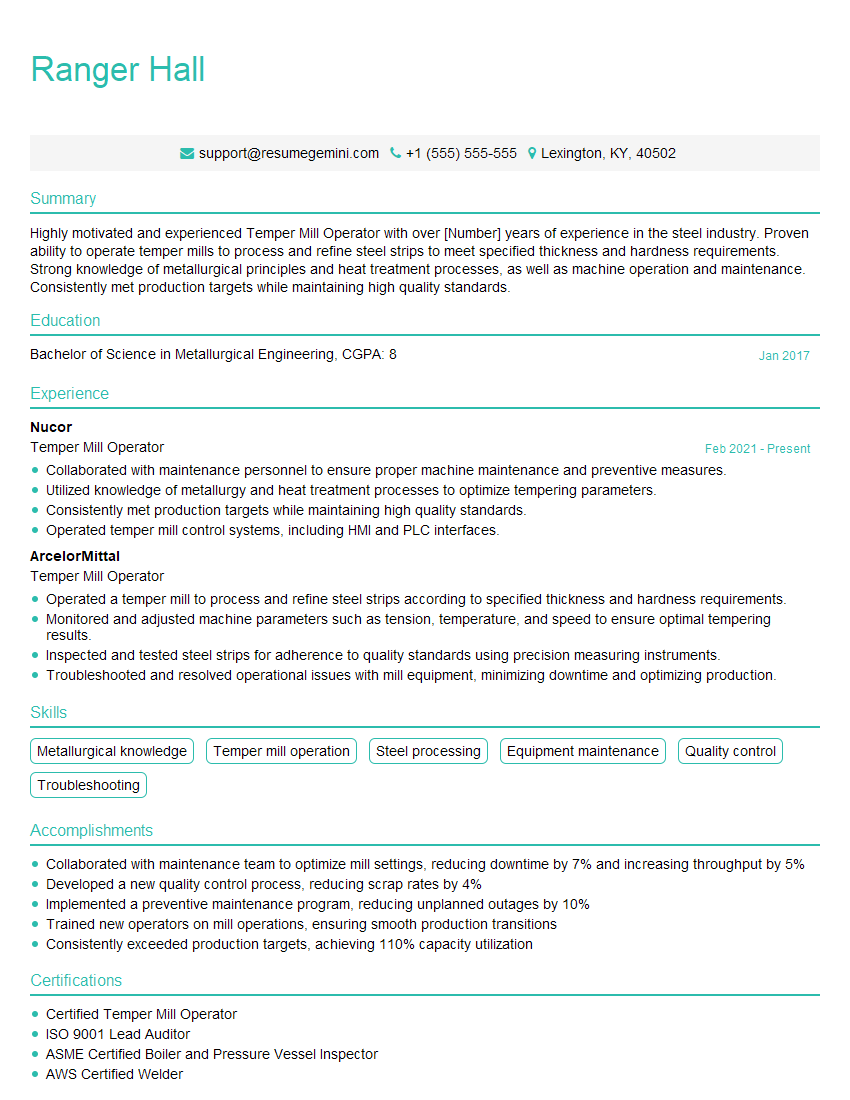

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Temper Mill Operator

1. What types of temper mill equipment have you operated in the past?

In my previous role at [Company Name], I operated a wide range of temper mill equipment, including both batch-type and continuous-type machines. I am proficient in using equipment from leading manufacturers such as Danieli, SMS Group, and Tenova.

2. What are the key parameters that need to be controlled during the temper mill process?

Strip tension

- Ensuring the strip is under the correct tension throughout the process is crucial for achieving the desired properties of the final product.

- I closely monitor the tension and make adjustments as needed to maintain the required levels.

Roll temperature

- The temperature of the rolls significantly impacts the properties of the tempered strip.

- I use temperature control systems to maintain the rolls at the precise temperature specified for the particular material being processed.

3. How do you troubleshoot common temper mill problems, such as strip breakage or poor surface finish?

I have extensive experience in troubleshooting various temper mill problems. For instance, if strip breakage occurs, I check for issues with the roll setup, lubrication, or strip tension. In the case of poor surface finish, I examine the roll condition, roll alignment, and lubrication to identify the underlying cause.

4. What preventive maintenance tasks are typically performed on temper mill equipment?

- Regularly inspect and clean the equipment to prevent breakdowns.

- Check and replace worn or damaged parts, such as bearings, seals, and couplings.

- Lubricate all moving parts according to the manufacturer’s specifications.

- Monitor and adjust the equipment’s operating parameters to ensure optimal performance.

5. How do you ensure the quality of the tempered strip meets the customer’s specifications?

I perform rigorous quality control checks throughout the tempering process. This includes visually inspecting the strip for defects, measuring its thickness, width, and hardness, and conducting tensile tests to assess its mechanical properties. I maintain detailed records of all quality control data and take corrective actions if any deviations from specifications are detected.

6. What is your experience with working in a team environment?

In my previous role, I was part of a team responsible for operating and maintaining the temper mill line. I effectively coordinated with other team members to ensure smooth production flow, troubleshoot problems, and implement process improvements. I am confident in my ability to work collaboratively and contribute to team success.

7. How do you stay up-to-date with the latest advancements in temper mill technology?

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Network with other temper mill professionals.

- Participate in training programs offered by equipment manufacturers.

8. What safety protocols do you follow when working in the temper mill area?

I am committed to maintaining a safe work environment and strictly adhere to all safety protocols. I wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves. I am trained in machine safety procedures and emergency response plans. I also actively participate in safety meetings and drills to enhance my knowledge and skills.

9. How do you handle situations when the temper mill is experiencing downtime?

When the temper mill experiences downtime, I prioritize identifying the root cause of the problem. I collaborate with maintenance technicians to repair or replace faulty equipment, and I make adjustments to the process parameters to minimize production losses. I also communicate with customers to keep them informed of the situation and estimated repair time.

10. What is your understanding of the temper mill’s role in the overall steel production process?

The temper mill plays a crucial role in the steel production process by enhancing the properties of cold-rolled steel. It improves the strip’s strength, hardness, and ductility, making it suitable for various applications, such as automotive parts, appliances, and construction materials. I understand how the temper mill’s output directly impacts the quality of the final products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Temper Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Temper Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Temper Mill Operator is responsible for the safe and efficient operation of a temper mill, monitoring the temperature, tension, and speed of the metal strip as it passes through the mill. They ensure that the final product meets the desired specifications and quality standards.

1. Operate and Monitor Temper Mill

Temper Mill Operators control and monitor the temper mill, ensuring the smooth functioning of the equipment. They make necessary adjustments to the operating parameters, such as temperature, tension, and speed, to achieve the desired outcome.

- Configure and operate temper mill according to production specifications

- Monitor temperature, tension, and speed of metal strip during processing

- Identify and correct operating problems to maintain optimal mill performance

2. Manage Material Handling

They handle raw materials and finished products, ensuring their proper handling and storage. This includes loading and unloading materials, inspecting them for defects, and maintaining inventory levels.

- Load and unload metal coils onto and off of the mill

- Inspect metal strip for defects and ensure proper handling

- Maintain inventory of raw materials and finished products

3. Ensure Quality Control

Temper Mill Operators conduct quality control checks on the metal strip throughout the tempering process. They verify that the material meets customer specifications, identifying any defects or deviations from the required standards.

- Conduct quality checks on metal strip to ensure it meets specifications

- Identify and resolve defects or deviations from quality standards

- Maintain records of quality control checks and corrective actions taken

4. Perform Maintenance and Repair

They perform routine maintenance and repairs on the temper mill and related equipment. This involves inspecting, cleaning, lubricating, and adjusting components to ensure optimal functionality and prevent breakdowns.

- Inspect and clean temper mill equipment to identify potential issues

- Perform routine maintenance and repair tasks as needed

- Troubleshoot and resolve equipment malfunctions

Interview Tips

To ace your Temper Mill Operator interview, it’s crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Role

Before the interview, take time to research the company and the specific role. This will help you understand their business, their values, and the expectations for the position. You can visit the company’s website, check industry news, and read reviews to gather insights.

- Research the company’s history, products/services, and industry standing

- Read job description thoroughly to understand the responsibilities and requirements

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact. Use specific examples to showcase your abilities in operating and maintaining temper mills, handling materials, ensuring quality control, and performing maintenance.

- Quantify your accomplishments using specific metrics and data points

- Provide examples of your problem-solving abilities and how you have overcome challenges

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Research potential questions related to the role, such as “Why are you interested in this position?” or “Describe a time you faced a challenge in operating a temper mill.” Practice your responses to convey your skills and enthusiasm effectively.

- Prepare answers to behavioral interview questions using the STAR method (Situation, Task, Action, Result)

- Consider questions about your experience with specific temper mill equipment or processes

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that show you have thoroughly researched the company and the role. Ask about the company’s growth plans, their commitment to employee development, or the specific challenges and opportunities involved in the position.

- Ask questions about the company’s future plans and how the role contributes to them

- Inquire about opportunities for professional development and training

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Temper Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.