Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Beveler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

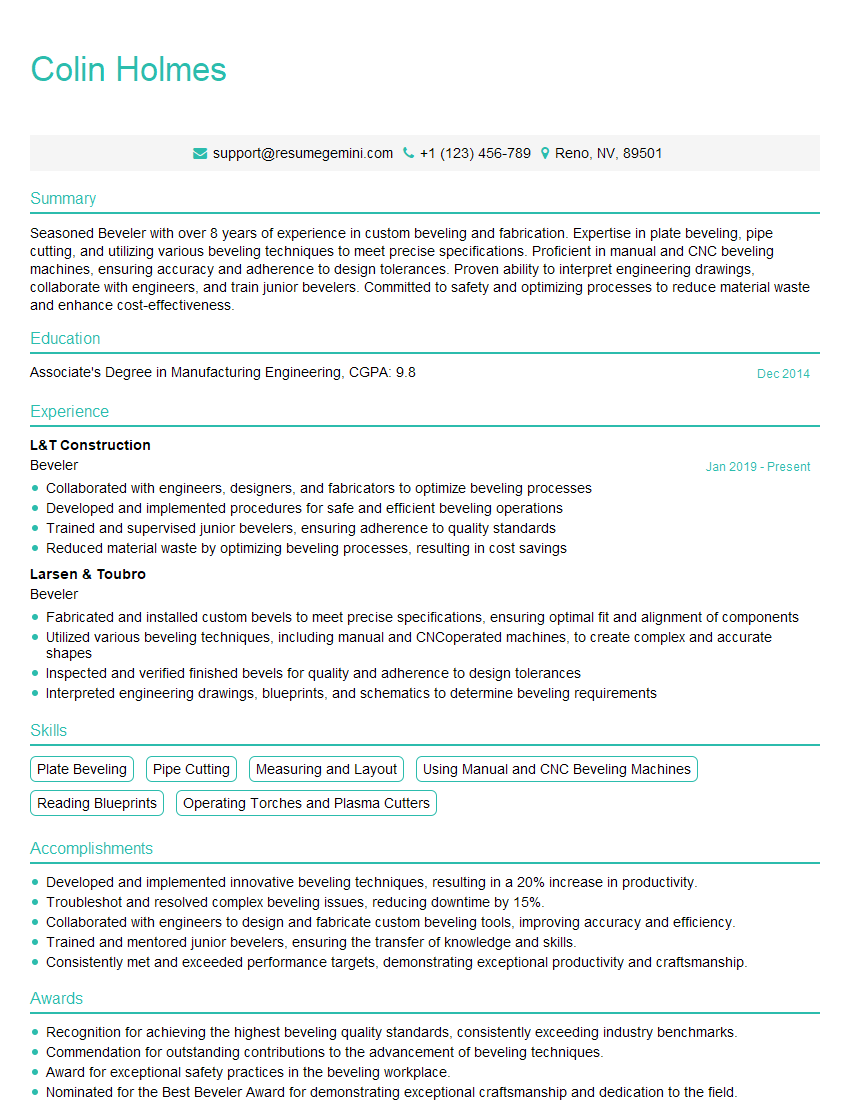

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beveler

1. What are the different types of bevels and how are they used in manufacturing?

In manufacturing, there are several types of bevels, each serving a specific purpose:

- Straight bevel: A straight bevel involves cutting a straight angle at the edge of a workpiece, creating a slanted surface. It is commonly used in welding, pipe fitting, and sheet metal fabrication.

- Compound bevel: A compound bevel involves cutting multiple angles on the edge of a workpiece, creating a more complex bevel. This type of bevel is often used in carpentry, woodworking, and metalworking.

- Counterbore bevel: A counterbore bevel involves cutting a conical recess into the surface of a workpiece, creating a tapered hole. This type of bevel is commonly used to accommodate countersunk screws or bolts.

- Countersink bevel: A countersink bevel involves cutting a conical recess into the surface of a workpiece, creating a wider, shallower hole. This type of bevel is commonly used to accommodate countersunk rivets or screws.

2. What are the key factors to consider when selecting a beveling tool?

Tool Type:

- Manual bevelers: Handheld tools that require manual operation.

- Power bevelers: Machine-operated tools that provide greater precision and efficiency.

Material Thickness:

- Consider the thickness of the material being beveled to ensure the tool has the appropriate capacity.

Bevel Angle:

- Select a tool that can achieve the desired bevel angle.

Material Type:

- Different materials have different beveling requirements. Consider the material’s hardness and thickness.

3. How do you ensure accuracy and precision when beveling?

- Use calibrated tools: Ensure that your beveling tools are properly calibrated to provide accurate measurements.

- Secure the workpiece: Clamp or hold the workpiece securely to prevent movement during beveling.

- Follow the manufacturer’s instructions: Refer to the tool manufacturer’s guidelines for proper operation and maintenance.

- Inspect your work: Regularly check the bevel angle and workpiece dimensions to ensure they meet specifications.

4. What are the common problems encountered during beveling and how do you troubleshoot them?

- Inconsistent bevel angle: This can be caused by improper tool calibration, workpiece movement, or dull cutting blades. Ensure proper calibration, secure the workpiece, and replace worn blades.

- Burrs or rough edges: This can be caused by blunt cutting blades or excessive feed rate. Use sharp blades and adjust the feed rate accordingly.

- Chatter or vibration: This can be caused by loose tool components, uneven workpiece surface, or incorrect clamping. Tighten loose components, ensure the workpiece is flat, and adjust clamping pressure.

5. How do you maintain and calibrate beveling tools to ensure optimal performance?

- Regular cleaning: Remove dirt, debris, and metal shavings from the tool and its components.

- Blade sharpening: Replace or sharpen dull blades to maintain cutting efficiency.

- Calibration: Use a protractor or other measuring device to verify and adjust the bevel angle as needed.

- Lubrication: Lubricate moving parts according to the manufacturer’s instructions to reduce wear and tear.

6. What safety precautions should be taken when using beveling tools?

- Wear appropriate PPE: Use safety glasses, gloves, and earplugs to protect yourself from flying debris and noise.

- Secure the workpiece: Ensure that the workpiece is securely clamped or held to prevent movement during operation.

- Avoid loose clothing: Loose clothing can get caught in moving parts, posing a safety hazard.

- Inspect tools before use: Check for damaged or worn components before operating the tool.

7. What is the difference between a cold bevel and a hot bevel?

- Cold bevel: Cutting and shaping a metal edge without applying heat. It is commonly used for metals that are not easily deformed, such as stainless steel or aluminum.

- Hot bevel: Cutting and shaping a metal edge while applying heat to the workpiece. This method is used for metals that are more easily deformed, such as mild steel or copper.

8. What are the advantages and disadvantages of using a water jet beveler?

Advantages:

- Precision and accuracy: Water jet bevelers provide precise and accurate bevels, reducing the need for rework.

- Cold cutting: Water jet beveling does not generate heat, minimizing material deformation and heat-affected zones.

- No burrs: The water jet cutting process does not create burrs or rough edges, reducing the need for additional finishing operations.

Disadvantages:

- Slower cutting speed: Water jet beveling can be slower than other methods, especially for thicker materials.

- Water usage: Water jet beveling requires a constant supply of water, which can be a limiting factor in certain environments.

- Abrasive wear: The abrasive particles used in the water jet can cause wear on the cutting nozzle, requiring regular maintenance.

9. Explain the process of beveling a pipe using a portable beveling machine.

- Preparation: Secure the pipe, clean the beveling area, and mark the desired bevel angle.

- Machine setup: Position the beveling machine on the pipe, align the cutting head, and set the bevel angle.

- Beveling: Start the beveling machine and guide it along the pipe, ensuring the cutting head maintains the correct angle.

- Inspection: Check the bevel angle and surface finish to ensure they meet specifications.

10. What factors affect the quality of a beveled surface?

- Sharpness of the cutting tool: Dull blades can produce rough or uneven bevels.

- Feed rate: Excessive feed rate can cause chatter or vibration, affecting the surface finish.

- Material properties: The hardness and thickness of the material can influence the difficulty of beveling and the quality of the surface.

- Tool rigidity: A rigid tool setup minimizes deflection and ensures accurate beveling.

- Lubrication: Proper lubrication reduces friction and improves surface finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beveler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beveler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Beveler is responsible for preparing and finishing the edges of metal sheets, plates, and other metal components. The key job responsibilities of a Beveler include:

1. Preparing Metal Surfaces

Preparing metal surfaces for beveling involves cleaning and removing any dirt, rust, or other debris that may interfere with the beveling process. This may involve using solvents, brushes, or other cleaning tools.

- Cleaning metal surfaces using solvents, brushes, or other cleaning tools

- Removing any dirt, rust, or other debris that may interfere with the beveling process

2. Marking and Measuring

Marking and measuring the metal surface is crucial to ensure precise beveling. This involves determining the angle and length of the bevel and marking the metal accordingly. The Beveler uses measuring tools such as rulers, protractors, and calipers to ensure accuracy.

- Determining the angle and length of the bevel

- Marking the metal surface accordingly

- Using measuring tools such as rulers, protractors, and calipers to ensure accuracy

3. Cutting and Beveling

The Beveler uses specialized tools and equipment to cut and bevel the metal. This may involve using a plasma cutter, oxy-fuel torch, or other cutting tools. The Beveler must ensure that the bevel is cut to the correct angle and length, and that the edges are smooth and free of burrs.

- Using specialized tools and equipment to cut and bevel the metal

- Ensuring that the bevel is cut to the correct angle and length

- Ensuring that the edges are smooth and free of burrs

4. Finishing and Inspection

Once the beveling is complete, the Beveler will finish and inspect the work. This may involve grinding, polishing, or other finishing techniques to ensure that the bevel meets the required specifications. The Beveler will also inspect the bevel for any defects or imperfections.

- Finishing and inspecting the work

- Using grinding, polishing, or other finishing techniques

- Inspecting the bevel for any defects or imperfections

Interview Tips

Preparing for a Beveler interview requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the industry. This will give you a better understanding of the company’s culture, values, and business goals. It will also help you understand the current trends and challenges in the industry.

- Visit the company’s website

- Read industry publications

- Connect with current or former employees on LinkedIn

2. Practice Your Skills

Bevelers are expected to have strong technical skills. Practice your beveling skills before the interview so that you can confidently demonstrate your abilities. You can practice on scrap metal or take a beveling class.

- Practice cutting and beveling metal using a plasma cutter or oxy-fuel torch

- Practice measuring and marking metal surfaces

- Practice finishing and inspecting beveled edges

3. Prepare for Common Interview Questions

There are some common interview questions that you can expect in a Beveler interview. Be prepared to answer questions about your experience, skills, and knowledge of the industry. Here are some examples of common interview questions:

- Tell me about your experience as a Beveler.

- What are your strengths and weaknesses as a Beveler?

- Why are you interested in working for our company?

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. This shows that you are respectful of the company and the interviewer’s time.

- Wear a suit or business casual attire

- Arrive on time for the interview

Next Step:

Now that you’re armed with the knowledge of Beveler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Beveler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini