Are you gearing up for an interview for a Crimping Machine Operator for Metal position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Crimping Machine Operator for Metal and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

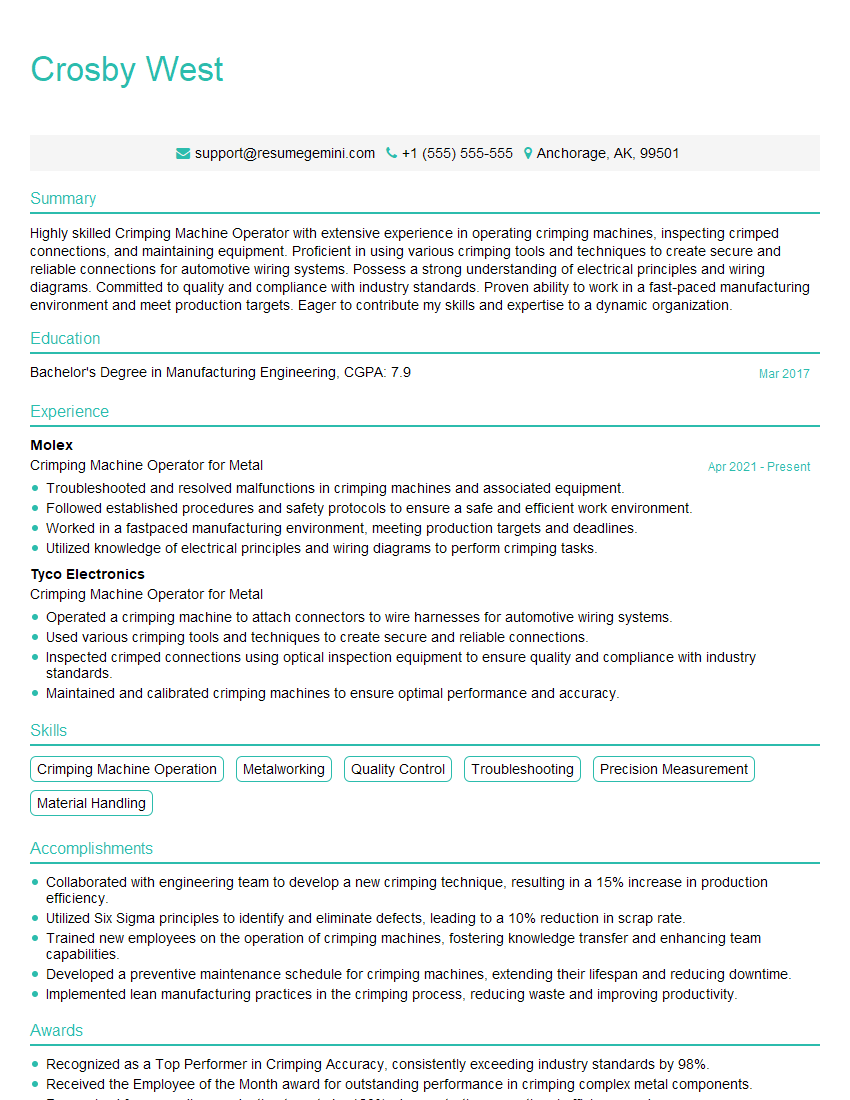

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crimping Machine Operator for Metal

1. Describe the key electrical components of a crimping machine and their functions?

The main electrical components of a crimping machine include:

- Power supply: Provides the necessary voltage and current to operate the machine.

- Motor: Converts electrical energy into mechanical energy to drive the crimping mechanism.

- Controller: Manages the operation of the machine, including the timing, force, and position of the crimping process.

- Sensors: Monitor the process parameters, such as pressure and temperature, to ensure proper operation.

2. Explain the different types of crimping methods used in metal crimping?

There are several types of crimping methods used in metal crimping:

- Indent crimping: Uses a die to create a permanent indentation in the metal, which holds the crimped connection together.

- Roll crimping: Uses two or more rotating dies to roll the metal, creating a continuous crimp.

- Swaging: Uses a punch to compress the metal around the connection, forming a tight crimp.

- Ultrasonic crimping: Uses ultrasonic vibrations to create a bond between the metal components.

3. What factors should be considered when selecting the appropriate crimping tool for a specific application?

When selecting a crimping tool, the following factors should be considered:

- Type of metal: Different metals have different properties, requiring specific crimping methods and tools.

- Wire size and type: The size and type of wire being crimped will determine the required crimping force and tool size.

- Connection type: The type of connection being made (e.g., terminal, splice) will affect the design of the crimping tool.

- Environmental conditions: The operating environment can influence the performance of the crimping tool.

4. What is the importance of proper crimp height and how do you ensure it is achieved?

Proper crimp height is critical for ensuring the reliability and performance of the crimped connection. It refers to the height of the crimp relative to the wire conductor.

To ensure proper crimp height, operators should:

- Use calibrated crimping tools: Regularly calibrate the crimping tool to ensure accurate measurements.

- Follow manufacturer’s specifications: Refer to the manufacturer’s guidelines for the specific wire and terminal combination.

- Visually inspect the crimps: Check the height and shape of the crimps to ensure they meet the required specifications.

5. Explain the function of a crimping die and how to maintain it properly?

A crimping die is a precision tool that forms the crimp on the wire conductor. It is made of hardened steel and has specific dimensions to ensure proper crimping.

To maintain a crimping die properly, operators should:

- Clean the die regularly: Remove any dirt or debris that can accumulate on the die surface.

- Inspect the die for wear or damage: Regularly check for any nicks, cracks, or burrs on the die, and replace it if necessary.

- Lubricate the die sparingly: Apply a small amount of lubricant to the die to reduce friction and prevent corrosion.

6. Describe the role of insulation crimping in the crimping process?

Insulation crimping, also known as barrel crimping, involves crimping a metal sleeve or barrel around the wire insulation to provide strain relief and protect the insulation from damage.

Proper insulation crimping ensures:

- Electrical insulation: Prevents short circuits by ensuring the insulation remains intact.

- Strain relief: Reduces stress on the wire connections and prevents conductor damage.

- Improved durability: Protects the insulation from environmental factors and mechanical wear.

7. Explain the principles behind the calibration of a crimping machine?

Calibration of a crimping machine involves adjusting the machine’s settings to ensure it produces consistent, high-quality crimps.

The calibration process typically includes:

- Setting the crimping force: Adjusting the pressure applied by the crimping dies to achieve the desired crimp height.

- Setting the crimp height: Using a height gauge to ensure the crimps meet the specified dimensions.

- Checking the crimp quality: Visually inspecting the crimps for proper formation and using a pull test to verify their strength.

8. Discuss the importance of adherence to crimping standards and specifications in the crimping industry?

Adherence to crimping standards and specifications is crucial for ensuring the safety and reliability of crimped connections.

These standards:

- Define performance requirements: Establish minimum performance criteria for crimping tools and connections.

- Ensure quality control: Provide guidelines for proper crimping techniques and inspection procedures.

- Promote safety: Mandate specific safety precautions and practices to minimize the risk of electrical accidents.

9. Describe the potential hazards associated with crimping operations and how to mitigate them?

Crimping operations involve working with electrical components and sharp tools, which pose several potential hazards:

- Electrical shock: Ensure proper insulation and grounding to prevent contact with live wires.

- Tool injuries: Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against sharp edges and flying debris.

- Repetitive motion injuries: Implement ergonomic practices and take regular breaks to reduce the risk of strain injuries.

10. Explain the troubleshooting steps you would take if a crimping machine is not producing acceptable crimps?

- Check the power supply and connections: Ensure the machine is receiving adequate power and all connections are secure.

- Inspect the dies and adjust the crimping force: Check for wear or damage on the dies and adjust the force to achieve the desired crimp height.

- Calibrate the machine: Perform a full calibration of the machine to ensure all settings are accurate.

- Check the wire and terminals: Confirm that the wire and terminals being used are compatible with the machine and specifications.

- Contact the manufacturer: If the issue persists, contact the machine manufacturer for technical support and guidance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crimping Machine Operator for Metal.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crimping Machine Operator for Metal‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Crimping Machine Operator for Metal is responsible for operating a crimping machine to join metal components. Key job responsibilities include:1. Machine Operation

Effectively operate the crimping machine to join metal components according to specified parameters.

- Load and unload metal components from the machine.

- Adjust machine settings to ensure proper crimping.

- Monitor machine operation for any abnormalities.

2. Quality Control

Ensure the quality of crimped components meets company standards.

- Inspect crimped components for defects.

- Conduct quality checks to ensure crimping meets specifications.

- Troubleshoot and resolve quality issues.

3. Process Improvement

Identify areas for process improvement and implement changes.

- Analyze production data and identify inefficiencies.

- Develop and implement process improvements to increase productivity.

- Provide feedback to management on potential improvements.

4. Equipment Maintenance

Perform basic maintenance and cleaning of the crimping machine.

- Clean and lubricate machine components.

- Inspect machine for wear and tear.

- Report any maintenance issues to supervisors.

Interview Tips

To prepare for an interview for the position of Crimping Machine Operator for Metal, consider these tips:1. Research the Company and Industry

Demonstrate your interest in the company and the metal crimping industry. Research the company’s products, services, and values. Familiarize yourself with industry trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in operating crimping machines and working with metal components. Quantify your accomplishments whenever possible. Use specific examples to illustrate your proficiency.

3. Prepare for Technical Questions

Anticipate technical questions about crimping machines, metal properties, and quality control processes. Review the basics of crimping techniques, different types of crimps, and common troubleshooting methods.

4. Practice Safety Procedures

Stress your understanding and adherence to safety protocols. Discuss your knowledge of lockout/tagout procedures, proper handling of metal components, and emergency response plans.

5. Show Enthusiasm and Teamwork

Convey your enthusiasm for working with machinery and your ability to contribute to a team environment. Highlight your willingness to learn, collaborate with colleagues, and improve processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crimping Machine Operator for Metal interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.