Are you gearing up for a career in Die Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Die Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

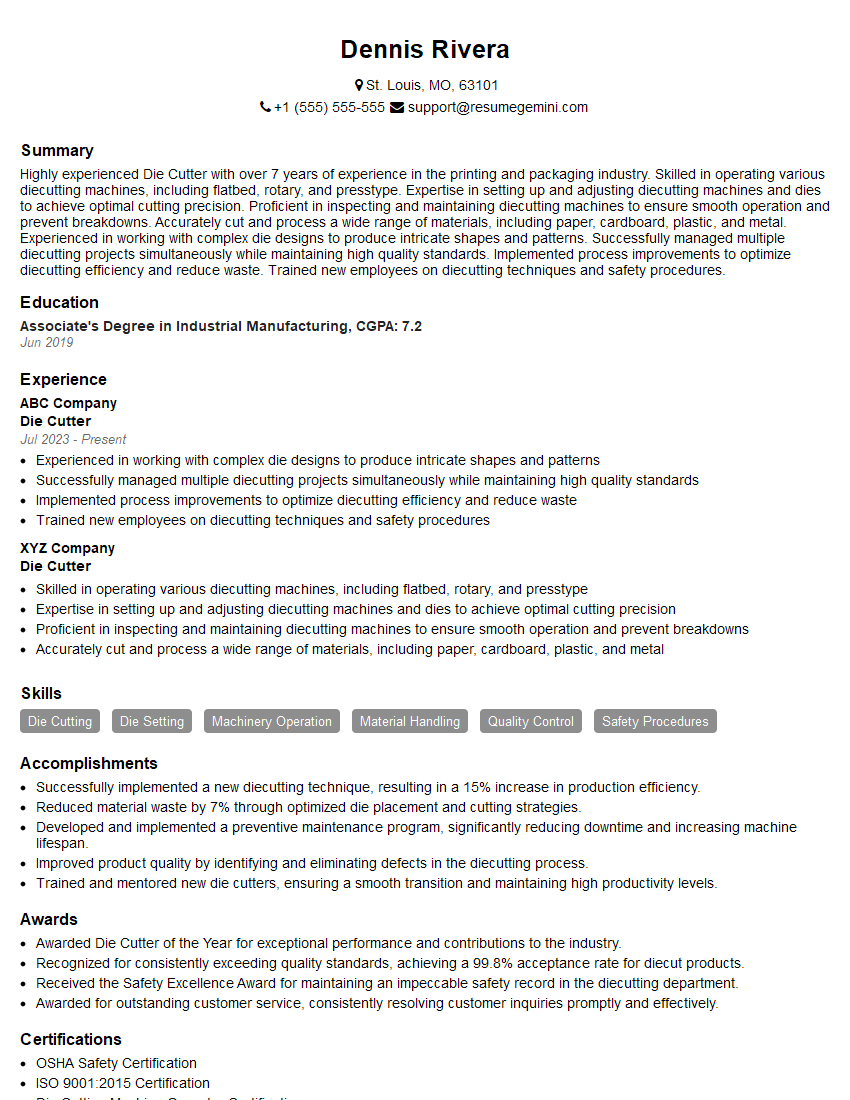

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Cutter

1. Describe the process of setting up a die-cutting machine for a specific project.

- Inspect the die and material to ensure compatibility.

- Mount the die onto the machine’s platen.

- Adjust the machine’s pressure, dwell time, and cutting speed based on material thickness and die specifications.

- Load the material into the machine’s feeder.

- Run a test cut to verify settings and make any necessary adjustments.

2. What factors can affect the quality of die-cut products?

Precision of the die:

- A sharp and well-maintained die is crucial for producing clean and precise cuts.

- Regular die maintenance and sharpening ensure optimal cutting quality.

Material selection:

- Different materials have varying cutting requirements.

- Choosing the appropriate material for the project is essential to achieve desired results.

Machine setup and calibration:

- Proper machine setup, including pressure and speed adjustments, is vital.

- Regular calibration ensures accurate and consistent cutting.

3. How do you ensure safety when operating a die-cutting machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Follow machine safety protocols and lockout/tagout procedures.

- Keep hands and fingers away from the cutting area.

- Inspect the machine and dies regularly for any damage or wear.

- Report any safety concerns or malfunctions promptly.

4. Describe the different types of dies used in die-cutting and their applications.

- Flat dies: Used for cutting flat materials like paper, cardboard, and plastic.

- Rotary dies: Used for continuous cutting of roll-fed materials like labels and packaging.

- Combination dies: Combine flat and rotary dies for complex cutting operations.

- Steel-rule dies: Used for cutting thick materials like metal and leather.

- Kiss-cut dies: Used for partially cutting materials to create decals or stickers.

5. How do you handle and store dies to ensure their longevity?

- Store dies in a clean and dry environment.

- Apply a thin layer of lubricant to prevent rust and corrosion.

- Use protective covers or cases when transporting dies.

- Handle dies carefully to avoid damage to the cutting edges.

- Regularly inspect dies for wear and tear, and repair or replace if necessary.

6. What are the common troubleshooting techniques for die-cutting problems?

- Poor cut quality: Check die sharpness, material compatibility, and machine settings.

- Material tearing: Adjust cutting pressure, use a sharper die, or consider a different material.

- Machine malfunction: Check for jams, power issues, or calibration errors.

- Excessive waste: Optimize die layout, reduce cutting speed, or consider a rotary die.

- Noise or vibration: Inspect machine components, lubricate, and ensure proper balancing.

7. How do you maintain and calibrate a die-cutting machine for optimal performance?

- Regular cleaning: Remove debris, dust, and oil to prevent machine damage.

- Lubrication: Lubricate moving parts to minimize friction and wear.

- Calibration: Verify and adjust cutting pressure, dwell time, and cutting speed as per manufacturer’s specifications.

- Component inspection: Check belts, bearings, and electrical components for damage or excessive wear.

- Software updates: Stay up-to-date with software updates to improve machine functionality and reliability.

8. Describe the different techniques used for die cutting different materials.

- Paper: Use flat dies with sharp cutting edges and adjust pressure and speed accordingly.

- Cardboard: Use thicker dies with higher pressure and slower speed to ensure clean cuts.

- Plastic: Use dies with special coatings or treatments to prevent material distortion during cutting.

- Metal: Use steel-rule dies with high-powered machines and appropriate safety precautions.

- Fabric: Use rotary dies with blades designed for specific fabric types and thicknesses.

9. How do you optimize die cutting processes to reduce waste and increase efficiency?

- Nest die layouts: Arrange dies efficiently on the material to minimize waste.

- Use sharp dies: Dull dies produce burrs and increase waste.

- Calibrate the machine: Proper calibration ensures accurate and consistent cutting, reducing material spoilage.

- Reduce setup time: Optimize die changes and material feeding to minimize downtime.

- Monitor machine performance: Identify areas for improvement and make adjustments to enhance efficiency.

10. What are the latest advancements in die-cutting technology that you are aware of?

- Laser die cutting: Non-contact cutting method that offers precision and versatility.

- Digital die cutting: Computer-controlled process that eliminates physical dies and allows for rapid prototyping.

- Automated die-cutting systems: Integrated machines that increase productivity and reduce labor costs.

- Advanced materials: New materials with improved cutting properties and durability.

- Software advancements: Die-cutting software with features for optimization and waste reduction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die cutters are responsible for operating and maintaining die-cutting machines, which are used to cut and shape materials such as paper, plastic, and metal. They work in a variety of industries, including printing, packaging, and manufacturing.

1. Operating Die-Cutting Machines

Die cutters must be able to operate die-cutting machines safely and efficiently. This includes setting up the machine, loading the material, and operating the controls.

- Set up and operate die-cutting machines to cut and shape materials according to specifications.

- Load and unload materials from the machine.

- Monitor the machine’s operation and make adjustments as needed.

2. Maintaining Die-Cutting Machines

Die cutters must also be able to maintain die-cutting machines. This includes cleaning and lubricating the machine, and replacing worn parts.

- Clean and lubricate die-cutting machines to ensure smooth operation.

- Inspect and replace worn or damaged parts.

- Perform routine maintenance tasks to keep the machine in good working order.

3. Quality Control

Die cutters must be able to inspect the finished product to ensure that it meets quality standards. This includes checking for defects such as tears, wrinkles, or miscuts.

- Inspect finished products for defects and ensure they meet quality standards.

- Identify and resolve any production issues.

- Maintain accurate records of production output and quality.

4. Safety

Die cutters must be able to work safely in a manufacturing environment. This includes following all safety procedures and wearing appropriate safety gear.

- Follow all safety procedures and wear appropriate safety gear.

- Identify and assess potential hazards in the workplace.

- Take steps to minimize risks and ensure a safe work environment.

Interview Tips

Preparing for a die cutter interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and what they are looking for in a die cutter.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to stay up-to-date on the latest trends and developments.

- Network with people who work in the industry to get insights into the company and the position.

2. Prepare your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to prepare your answers to these questions so that you can deliver them confidently and concisely.

- Practice answering common interview questions out loud.

- Get feedback from a friend or family member on your answers.

- Tailor your answers to the specific job you are applying for.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive for your interview 5-10 minutes early to give yourself time to relax and collect your thoughts.

- Bring a portfolio of your work to showcase your skills.

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest and upfront about your skills and experience.

- Be enthusiastic and passionate about the position you are applying for.

- Ask questions to show that you are interested and engaged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.