Are you gearing up for an interview for a Kick Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Kick Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

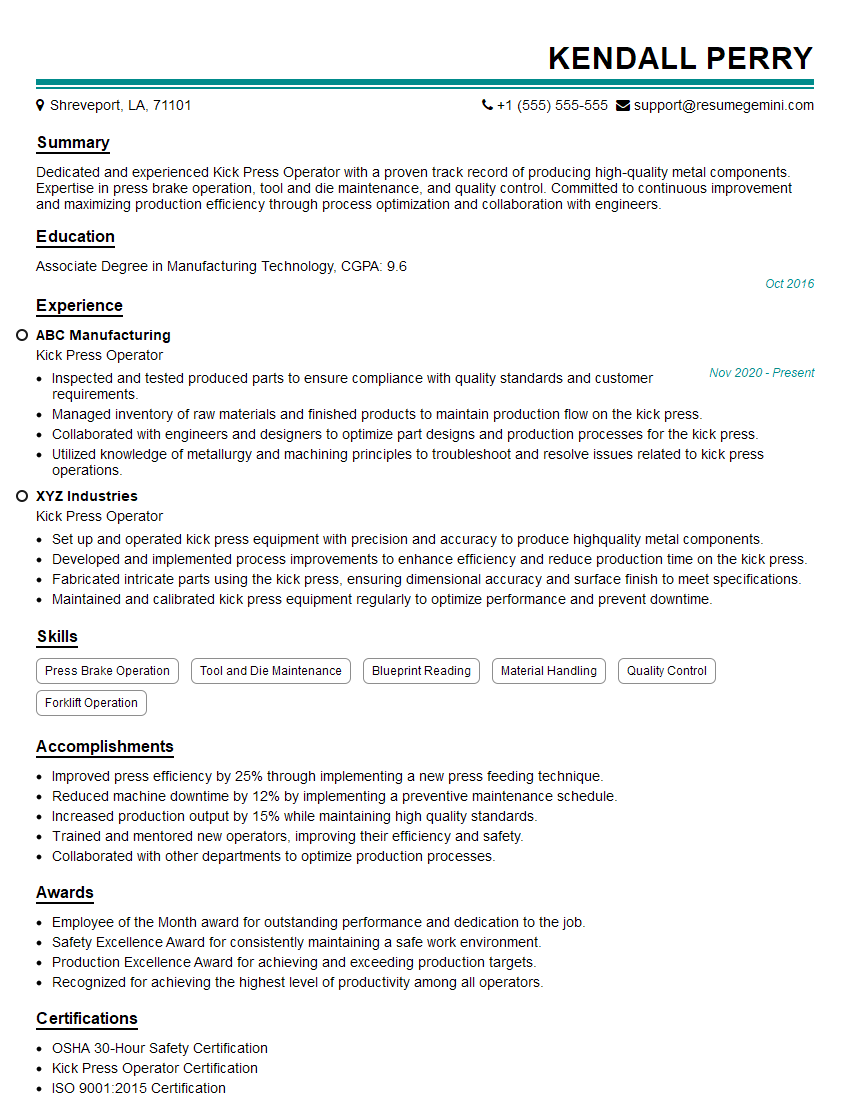

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kick Press Operator

1. Describe the process of setting up a kick press machine?

- Locate the machine in a well-ventilated area with adequate lighting.

- Level the machine using a spirit level and adjust the feet accordingly.

- Connect the machine to a power source and ensure proper electrical connections.

- Install the appropriate tooling, including dies, punches, and stripper plates.

- Lubricate the machine’s moving parts as per the manufacturer’s instructions.

- Set the machine’s operating parameters, such as pressure, stroke length, and speed.

- Perform a trial run to ensure that the machine is functioning properly.

2. What are the safety precautions that must be followed when operating a kick press?

Safe Operating Practices:

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Keep hands clear of the operating area during machine operation.

- Remain alert and focused on the task at hand.

- Never operate the machine under the influence of drugs or alcohol.

- Keep the work area clean and free of debris.

Machine Maintenance:

- Regularly inspect the machine for any signs of damage or wear.

- Lubricate moving parts according to the manufacturer’s instructions.

- Keep the machine clean by removing any metal shavings or debris.

3. How do you troubleshoot a kick press machine that is not functioning properly?

- Check the power source and electrical connections to ensure that the machine is receiving power.

- Inspect the tooling for any signs of damage or wear.

- Check the machine’s hydraulic system for any leaks or blockages.

- Lubricate the machine’s moving parts to reduce friction.

- Reset the machine’s control system to default settings.

- Consult the machine’s manual for specific troubleshooting procedures.

- If the problem persists, contact a qualified technician for assistance.

4. What is the difference between a mechanical kick press and a hydraulic kick press?

-

Mechanical Kick Press:

- Uses a mechanical flywheel to generate force.

- Operated manually or with a foot pedal.

- Typically used for smaller, less demanding operations. Hydraulic Kick Press:

- Uses hydraulic pressure to generate force.

- Controlled electronically, offering greater precision and repeatability.

- Capable of handling larger, more complex operations.

5. What are the different types of materials that can be formed using a kick press?

- Sheet metal (steel, aluminum, stainless steel, etc.)

- Plastic

- Rubber

- Leather

- Composite materials

6. What is the purpose of a stripper plate in a kick press?

- Prevents the material from sticking to the punch.

- Guides the material during the forming process.

- Strips the formed part from the punch after the operation.

- Improves the quality and precision of the formed parts.

7. How do you maintain the accuracy of a kick press?

- Regularly calibrate the machine using precision measuring tools.

- Use high-quality tooling that is properly sharpened and maintained.

- Ensure that the machine is properly leveled and aligned.

- Lubricate the machine’s moving parts to reduce friction and wear.

- Monitor the machine’s performance and make adjustments as needed.

8. What is the maximum tonnage capacity of a kick press that you have operated?

- Answer with the specific tonnage capacity, for example: “I have operated a kick press with a maximum tonnage capacity of 50 tons.”

9. Describe a challenging project that you worked on using a kick press.

- Provide a specific example of a project that involved complex forming or tight tolerances.

- Explain how you overcame the challenges and achieved the desired results.

10. What is your preferred method for setting the clearance between the punch and the die?

- Explain your preferred method, which could include using shims, feeler gauges, or a dial indicator.

- Describe the advantages and disadvantages of your chosen method.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kick Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kick Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Kick Press Operator is responsible for operating and maintaining a kick press, used in stamping, forming, and cutting operations. The primary function of this role is to ensure the efficient and safe production of high-quality metal parts.

1. Machine Operation and Maintenance

Start, stop, and monitor the kick press throughout the production process.

- Set up and adjust the press according to specifications.

- Inspect and maintain the press, including lubrication, cleaning, and minor repairs.

2. Material Handling

Load and unload materials into and out of the press.

- Position materials correctly to ensure accurate stamping or forming.

- Inspect materials for defects prior to feeding them into the press.

3. Quality Control

Visually inspect finished parts for defects, such as cracks, burrs, and dimensional inaccuracies.

- Take corrective actions to adjust the press or process to improve product quality.

- Maintain records of quality checks and production output.

4. Safety and Compliance

Adhere to all safety regulations and company policies while operating the kick press.

- Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Maintain a clean and organized work area.

Interview Tips

To ace your interview, it is crucial to prepare thoroughly. Here are some key tips to help you stand out from other candidates:

1. Research the Company and Position

Before the interview, take the time to research the company, its products, and its industry. This will demonstrate your interest in the position and show that you have taken the time to understand the company’s needs.

- Visit the company website and social media pages.

- Read industry news and articles to stay up-to-date on the company’s competitors and trends.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions concisely and effectively, highlighting your relevant skills and experiences.

- Use the STAR method to structure your answers, providing specific examples of your work experience.

- Tailor your answers to the specific job requirements.

3. Prepare Specific Questions for the Interviewer

Asking well-thought-out questions during the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company.

- Ask about the company’s culture and values.

- Inquire about the specific responsibilities of the Kick Press Operator role.

4. Be Confident and Professional

During the interview, maintain a positive and confident demeanor. Dress professionally and arrive on time. Make eye contact with the interviewer and speak clearly and concisely.

- Be prepared to discuss your strengths and weaknesses.

- Be enthusiastic and show that you are genuinely interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Kick Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!