Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Punch Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

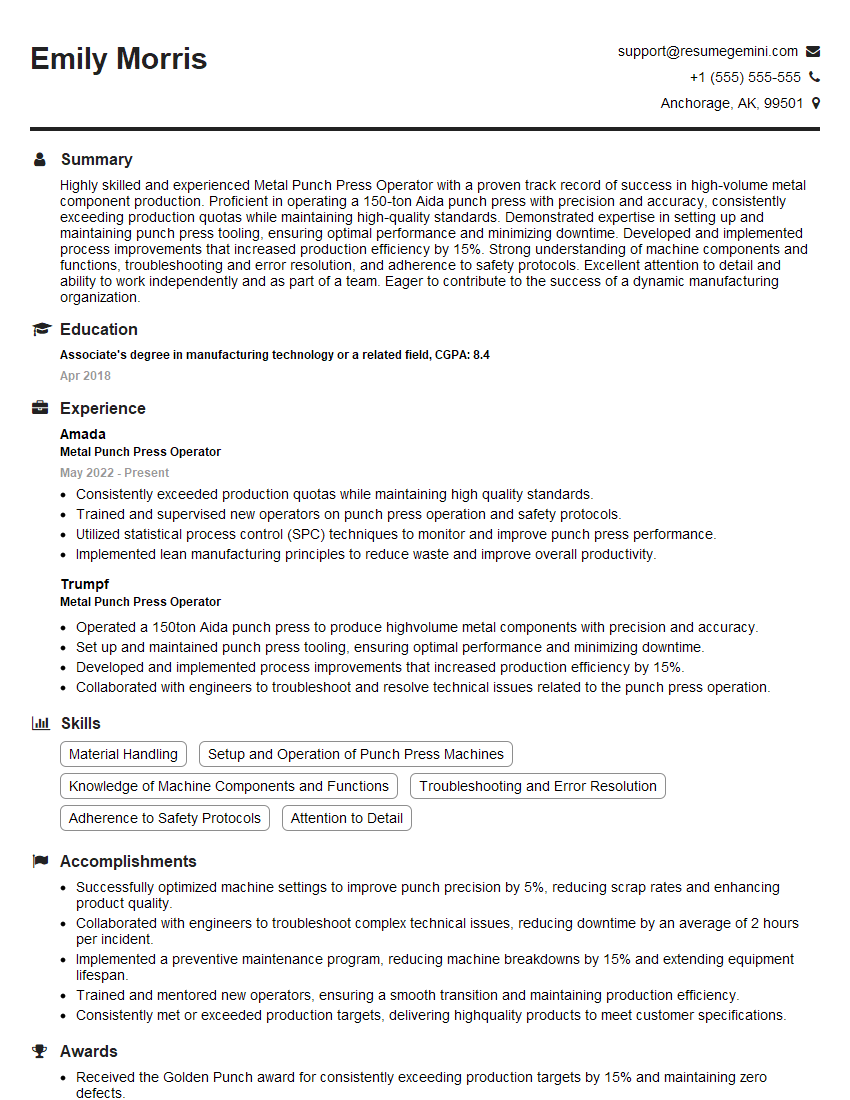

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Punch Press Operator

1. How would you set up a metal punch press for a new job?

- First, I would read the job setup sheet to understand the requirements of the job.

- Next, I would gather the necessary materials, including the metal sheet, the punch, and the die.

- I would then mount the punch and die to the press and adjust the settings according to the job setup sheet.

- Finally, I would test the setup by running a few pieces of metal through the press to ensure that the parts are being produced correctly.

2. What are the different types of metal punch presses?

C-frame presses

- C-frame presses are the most common type of punch press.

- They are characterized by their C-shaped frame, which provides rigidity and support.

- C-frame presses are available in a variety of sizes and capacities.

O-frame presses

- O-frame presses are similar to C-frame presses, but they have a more open frame design.

- This design provides greater access to the work area, which can be helpful for larger or more complex jobs.

- O-frame presses are typically more expensive than C-frame presses.

Straight-sided presses

- Straight-sided presses have a rectangular frame that is open on all four sides.

- This design provides the greatest access to the work area, but it also makes the press less rigid than C-frame or O-frame presses.

- Straight-sided presses are typically used for large or heavy-duty jobs.

3. What are the safety precautions that should be taken when operating a metal punch press?

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Never operate a punch press that is not properly guarded.

- Keep your hands away from the point of operation.

- Never reach over or under a moving ram.

- Be aware of the location of the emergency stop button and how to use it.

4. What are the different types of punches and dies used in metal punch presses?

Punches

- Punches are the tools that cut the metal sheet.

- They are made from a variety of materials, including tool steel, carbide, and ceramic.

- The shape of the punch will determine the shape of the hole that is cut.

Dies

- Dies are the tools that support the metal sheet during the punching process.

- They are also made from a variety of materials, including tool steel, carbide, and ceramic.

- The shape of the die will determine the shape of the finished part.

5. What are the different types of materials that can be punched using a metal punch press?

- Metal punch presses can be used to punch a variety of materials, including:

- Steel

- Aluminum

- Copper

- Brass

- Plastic

6. What are the different types of operations that can be performed using a metal punch press?

- Metal punch presses can be used to perform a variety of operations, including:

- Punching holes

- Cutting shapes

- Embossing

- Forming

- Bending

7. What are the advantages of using a metal punch press?

- Metal punch presses are fast and efficient.

- They can produce high-quality parts with precise tolerances.

- They are relatively easy to operate.

- They can be used to perform a variety of operations.

8. What are the disadvantages of using a metal punch press?

- Metal punch presses can be dangerous if they are not operated properly.

- They can be noisy and vibrate, which can be a nuisance.

- They can be expensive to purchase and maintain.

9. How do you troubleshoot a metal punch press?

- If a metal punch press is not working properly, there are several things that you can do to troubleshoot the problem:

- First, check to make sure that the press is properly connected to power.

- Next, check the hydraulic fluid level and make sure that it is at the proper level.

- If the hydraulic fluid level is low, add more fluid and then try to operate the press again.

- If the press still does not work, check the electrical connections and make sure that they are all tight.

- If the electrical connections are all tight, then the problem may be with the press itself.

- In this case, you should contact a qualified technician to have the press repaired.

10. What are the maintenance requirements for a metal punch press?

- Metal punch presses require regular maintenance to ensure that they operate properly and safely.

- Some of the maintenance tasks that should be performed on a regular basis include:

- Checking the hydraulic fluid level and adding fluid as needed.

- Greasing the moving parts of the press.

- Inspecting the punches and dies for wear and tear.

- Cleaning the press and removing any debris.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Punch Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Punch Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary responsibility of a Metal Punch Press Operator is to oversee and operate a metal punch press to cut, shape, and form metal components. This involves ensuring the safe and efficient operation of the press, maintaining the equipment, and performing quality checks on the produced parts.

1. Press Operation

The primary duty of an operator is to operate the metal punch press, which is used to cut, shape, and form metal components. This requires the operator to:

- Load and secure metal sheets or strips into the press

- Select and install the appropriate tooling for the desired operation

- Adjust the press settings, such as pressure, speed, and stroke length

- Initiate the punching process and monitor its progress

- Unload the finished parts and inspect them for quality

2. Machine Maintenance

Maintaining the metal punch press in optimal condition is essential for its efficient and safe operation. The operator is responsible for:

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs

- Monitoring the press for any signs of wear or damage

- Reporting any maintenance issues to supervisors or maintenance personnel

- Following established safety protocols and procedures

3. Quality Assurance

The operator is responsible for ensuring the quality of the parts produced by the metal punch press. This involves:

- Inspecting the finished parts for defects, such as burrs, scratches, or dimensional inaccuracies

- Measuring and verifying the dimensions of the parts using measuring tools and instruments

- Maintaining quality records and reporting any non-conformance issues

4. Material Handling

The operator is also responsible for handling the metal sheets and strips used in the punching process. This involves:

- Loading and unloading metal materials onto and off of the press

- Positioning and aligning the materials correctly to ensure accurate punching

- Using appropriate material handling equipment, such as forklifts or cranes, when necessary

Interview Tips

To ace your interview for the Metal Punch Press Operator position, consider the following tips and preparation strategies:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, services, and industry standing. Understanding the company’s operations and goals will help you demonstrate your enthusiasm for the role and its alignment with your career aspirations.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating metal punch presses, including your ability to set up and adjust the equipment, monitor its operation, and perform maintenance. Highlight any experience in quality control, material handling, and safety protocols.

3. Showcase Safety Awareness

Metal punch press operation involves potential safety hazards. Emphasize your understanding of safety procedures, including lockout/tagout, machine guarding, and personal protective equipment. Share any experience with implementing or improving safety measures in previous roles.

4. Demonstrate Attention to Detail

Accuracy and precision are crucial in this role. Highlight your meticulous nature and ability to focus on details. Provide examples of how you have maintained high levels of accuracy in your previous work, whether in manufacturing, inspection, or other relevant fields.

5. Prepare for Common Interview Questions

Anticipate questions related to your technical skills, experience, and safety awareness. Practice answering them concisely and confidently. Consider preparing specific examples that showcase your abilities and qualifications for the role.

- Tell me about your experience operating metal punch presses.

- How do you ensure the quality of the parts produced by the press?

- What safety protocols do you follow when operating a metal punch press?

- How do you handle and resolve any issues or malfunctions that may occur during the operation of the press?

- Why are you interested in working as a Metal Punch Press Operator for our company?

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive on time for your interview. Punctuality demonstrates respect for the interviewer and the company.

7. Be Enthusiastic and Confident

Showcasing your enthusiasm for the role and the industry can make a positive impact. Be confident in your abilities and articulate your desire to contribute to the company’s success.

8. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions about the company’s operations, growth plans, and safety culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Punch Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.