Are you gearing up for a career in Plate Slitter and Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Plate Slitter and Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

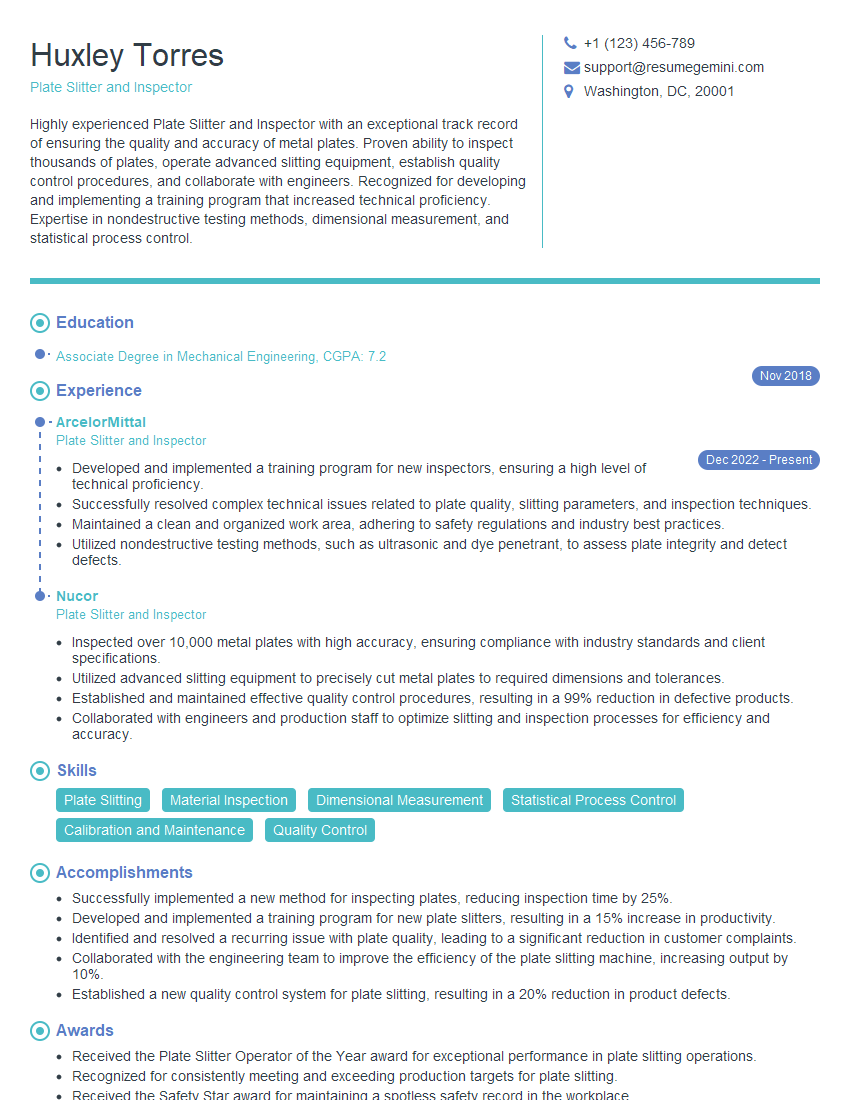

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Slitter and Inspector

1. Explain the process of slitting plates?

Plate slitting is the process of cutting large sheets of metal into narrower strips. It is a vital step in the production of many metal products, including roofing, siding, and automotive parts. The process begins with a large coil of metal, which is fed into a slitter. The slitter uses a series of rotating blades to cut the metal into strips of the desired width. The strips are then coiled up and packaged for shipment.

- Loading the coil onto the slitter

- Setting up the slitter blades

- Starting the slitter and feeding the coil into the machine

- Monitoring the slitter and making adjustments as needed

- Unloading the finished coils

2. What are the different types of slitters?

Center Slitters

- Designed for high-precision slitting of thin materials

- Utilizes specialized tooling and tension control systems

- Produces strips with precise widths and clean edges

Peripheral Slitters

- Used for general-purpose slitting of a wide range of materials

- Offers high productivity and versatility

- Capable of handling various thicknesses and coil weights

Gang Slitters

- Employs multiple blades to simultaneously slit multiple strips from a single coil

- Increases production efficiency for high-volume applications

- Requires precise blade alignment and tension control

3. What are the key factors to consider when selecting a slitter?

When selecting a slitter, it is important to consider the following factors:

- The type of material to be slit

- The desired width of the strips

- The production volume

- The budget

4. What are the common defects that can occur during slitting?

The common defects that can occur during slitting include:

- Edge burrs

- Scratches

- Uneven widths

- Coil breaks

5. How can these defects be prevented?

These defects can be prevented by taking the following steps:

- Using sharp blades

- Setting the blades correctly

- Maintaining the slitter properly

- Using the correct tension settings

- Inspecting the coils before and after slitting

6. What are the different types of plate inspectors?

The different types of plate inspectors include:

- Visual inspectors

- Ultrasonic inspectors

- Magnetic particle inspectors

- Eddy current inspectors

7. What are the responsibilities of a plate inspector?

The responsibilities of a plate inspector include:

- Inspecting plates for defects

- Identifying and classifying defects

- Reporting defects to the appropriate personnel

- Maintaining inspection records

8. What are the different types of plate defects?

The different types of plate defects include:

- Surface defects

- Subsurface defects

- Laminations

- Cracks

- Inclusions

9. How are plate defects detected?

Plate defects can be detected using a variety of methods, including:

- Visual inspection

- Ultrasonic inspection

- Magnetic particle inspection

- Eddy current inspection

10. What are the acceptance criteria for plate defects?

The acceptance criteria for plate defects vary depending on the application. However, some general guidelines include:

- Surface defects must not exceed a certain depth or width

- Subsurface defects must not exceed a certain size or number

- Laminations must not exceed a certain thickness or length

- Cracks are not acceptable

- Inclusions are not acceptable

11. What is the difference between a plate slitter and a plate inspector?

A plate slitter is a machine that cuts plates into strips. A plate inspector is a person who inspects plates for defects.

12. What are the qualifications for a plate slitter operator?

The qualifications for a plate slitter operator typically include:

- A high school diploma or equivalent

- Experience operating a plate slitter

- Knowledge of plate slitter safety procedures

- Ability to read and understand technical drawings

- Ability to work independently and as part of a team

13. What are the qualifications for a plate inspector?

The qualifications for a plate inspector typically include:

- A high school diploma or equivalent

- Experience inspecting plates

- Knowledge of plate inspection procedures

- Ability to read and understand technical drawings

- Ability to work independently and as part of a team

14. What is the work environment for a plate slitter operator or plate inspector?

Plate slitter operators and plate inspectors typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They may also be required to work in awkward positions.

15. What is the career outlook for a plate slitter operator or plate inspector?

The career outlook for plate slitter operators and plate inspectors is expected to be good over the next few years. The demand for these workers is expected to increase as the manufacturing industry continues to grow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Slitter and Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Slitter and Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plate Slitter and Inspector is responsible for setting up and operating plate slitting equipment to cut metal plates into various widths and ensuring the quality of the finished products.

1. Slitting and Cutting

Setting up and operating plate slitting equipment to cut metal plates into specified widths and lengths

- Adjusting slitting knives to achieve desired widths and tolerances

- Monitoring cutting process to ensure clean and accurate cuts

2. Inspection

Inspecting slit metal plates for defects, such as burrs, scratches, or dimensional inaccuracies

- Measuring dimensions and comparing them to specifications

- Identifying and marking defective plates for scrap or rework

3. Equipment Maintenance

Performing routine maintenance on slitting equipment to ensure optimal performance

- Cleaning and lubricating machines

- Replacing worn or damaged parts

4. Safety

Adhering to all safety regulations and procedures

- Wearing appropriate safety gear

- Following lockout/tagout procedures

Interview Tips

Preparing for a Plate Slitter and Inspector interview requires a combination of technical knowledge, situational awareness, and presentation skills.

1. Research the Company and Position

Thoroughly research the company and the specific position you are applying for. This will help you understand their needs and tailor your answers to their requirements.

- Visit the company website to learn about their products, services, and values.

- Read industry publications and news articles to stay up-to-date on the latest trends and best practices.

2. Practice Your Answers

Take the time to practice your answers to common interview questions.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Focus on highlighting your relevant skills and experience, and how they align with the job requirements.

3. Showcase Your Technical Abilities

Employers will be looking for candidates with a strong understanding of plate slitting operations.

- Be prepared to discuss your experience with different types of slitting equipment.

- Explain your knowledge of metalworking principles and quality control techniques.

4. Emphasize Your Safety Awareness

Safety is paramount in manufacturing environments.

- Discuss your knowledge of safety regulations and best practices.

- Explain how you ensure your own safety and the safety of others in the workplace.

5. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest in the position and the company.

- Prepare questions about the company’s growth plans, their commitment to safety, or their use of technology.

- These questions will also give you an opportunity to learn more about the organization and determine if it is a good fit for you.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Plate Slitter and Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.