Feeling lost in a sea of interview questions? Landed that dream interview for Pneumatic Press Hand but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pneumatic Press Hand interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

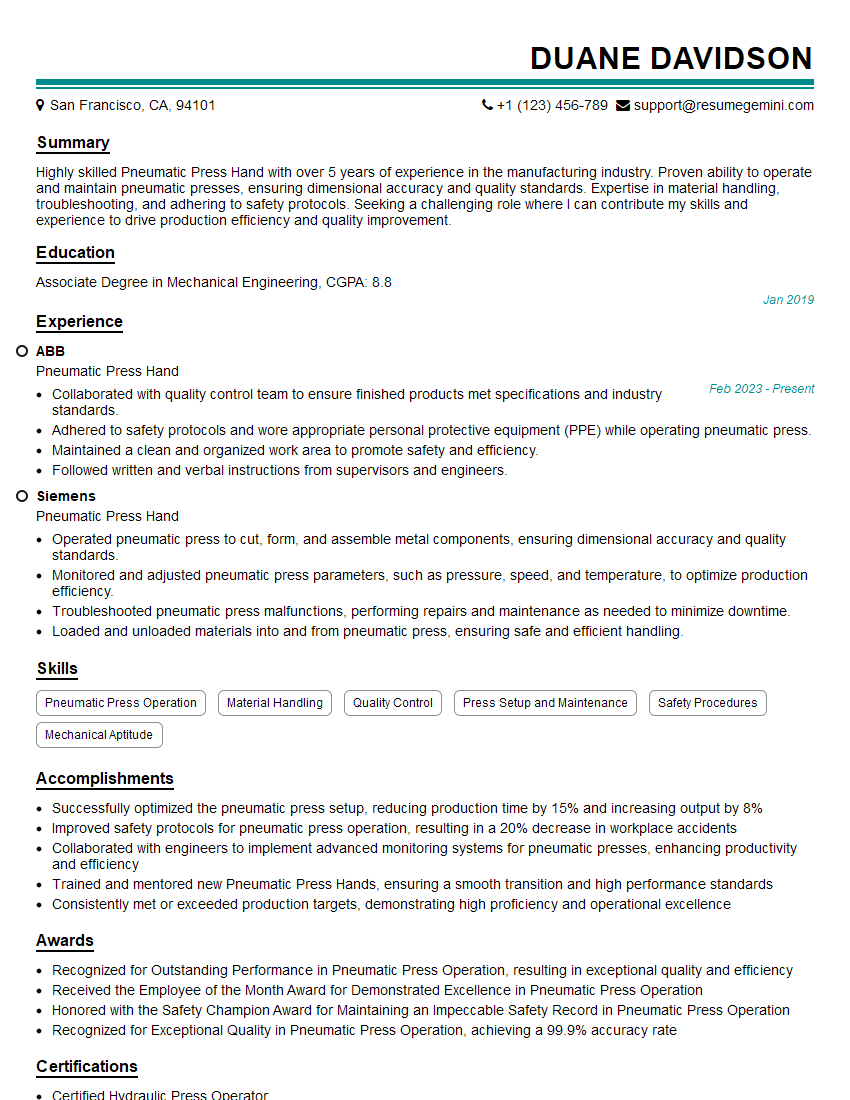

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pneumatic Press Hand

1. How would you ensure that the pneumatic press is operating at optimal efficiency?

- Regularly inspect the press for any signs of wear or damage

- Make sure that the air pressure is at the correct level

- Lubricate the moving parts regularly

- Clean the press regularly to remove any dirt or debris

- Monitor the press’s performance regularly and make adjustments as necessary

- Follow the manufacturer’s recommended maintenance schedule

2. How would you identify and troubleshoot common problems with a pneumatic press?

Troubleshooting Common Problems

- The press is not operating at the correct speed: Check the air pressure, the lubricator, and the air filter

- The press is making a strange noise: Check the moving parts for wear or damage

- The press is leaking air: Check the air lines for leaks, and the seals

- The press is not stopping properly: Check the brake system

- The press is not working at all: Check the power supply, the air supply, and the controls

3. How would you maintain the safety of yourself and others when operating a pneumatic press?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves

- Make sure that the press is properly guarded

- Never put your hands or any other body parts in the press while it is operating

- Always follow the manufacturer’s safety instructions

4. What are the different types of pneumatic presses?

- Air-over-oil presses: These presses use air pressure to actuate a piston, which in turn pressurizes oil. The oil then drives a hydraulic ram, which applies force to the workpiece.

- Air-over-hydraulic presses: These presses use air pressure to actuate a piston, which in turn pressurizes hydraulic fluid. The hydraulic fluid then drives a hydraulic ram, which applies force to the workpiece.

- Air-powered presses: These presses use air pressure to directly actuate a piston, which applies force to the workpiece.

5. What are the advantages and disadvantages of using a pneumatic press?

Advantages

- Pneumatic presses are relatively inexpensive to purchase and operate

- They are easy to set up and use

- They are versatile and can be used for a variety of applications

- They are relatively quiet

- They are clean and do not produce any fumes or emissions

Disadvantages

- Pneumatic presses are not as powerful as hydraulic presses

- They can be slow

- They can be noisy

- They can be dangerous if not properly operated

6. What types of materials can be formed using a pneumatic press?

- Sheet metal

- Plastic

- Rubber

- Wood

- Composite materials

7. What are the different types of dies that can be used with a pneumatic press?

- Blanking dies: These dies are used to cut out shapes from sheet metal

- Forming dies: These dies are used to shape sheet metal into complex shapes

- Drawing dies: These dies are used to draw sheet metal into a desired shape

- Piercing dies: These dies are used to punch holes in sheet metal

- Embossing dies: These dies are used to create raised designs on sheet metal

8. What are the safety procedures that must be followed when operating a pneumatic press?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves

- Make sure that the press is properly guarded

- Never put your hands or any other body parts in the press while it is operating

- Always follow the manufacturer’s safety instructions

9. What are the maintenance procedures that must be followed to keep a pneumatic press in good working condition?

- Regularly inspect the press for any signs of wear or damage

- Make sure that the air pressure is at the correct level

- Lubricate the moving parts regularly

- Clean the press regularly to remove any dirt or debris

- Monitor the press’s performance regularly and make adjustments as necessary

- Follow the manufacturer’s recommended maintenance schedule

10. What are the different applications for pneumatic presses?

- Stamping

- Bending

- Drawing

- Piercing

- Embossing

- Assembly

- Riveting

- Stapling

- Welding

- Cutting

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pneumatic Press Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pneumatic Press Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pneumatic Press Hand is responsible for operating pneumatic presses and maintaining them in good working condition. The day-to-day tasks may vary depending on the industry and the specific company, but some common key responsibilities include:

1. Operating Pneumatic Presses

This involves loading and unloading workpieces, setting up and adjusting the press, and monitoring the operation to ensure that the parts are produced to specification.

- Loading and unloading workpieces

- Setting up and adjusting the press

- Monitoring the operation to ensure that the parts are produced to specification

2. Maintaining Pneumatic Presses

This includes performing routine maintenance tasks such as cleaning, lubricating, and inspecting the press. It also involves troubleshooting and repairing any problems that may arise.

- Cleaning, lubricating, and inspecting the press

- Troubleshooting and repairing any problems that may arise

3. Quality Control

This involves inspecting the parts produced by the press to ensure that they meet the required quality standards. It also involves taking corrective action if any defects are found.

- Inspecting the parts produced by the press

- Taking corrective action if any defects are found

4. Safety

This is a critical aspect of the job and as a press hand, it is important to follow all safety procedures and regulations. It involves wearing the appropriate safety gear, such as gloves, safety glasses, and earplugs, and being aware of the potential hazards associated with operating a pneumatic press.

- Following all safety procedures and regulations

- Wearing the appropriate safety gear

- Being aware of the potential hazards associated with operating a pneumatic press

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of making a great impression and landing the job. Here are some interview tips and hacks that can help you ace your interview for a Pneumatic Press Hand position:

1. Research the Company and the Position

Take the time to learn about the company’s history, culture, and products. This will show the interviewer that you are interested in the position and that you have taken the time to prepare. You should also research the specific position you are applying for. This will help you understand the key responsibilities of the role and the qualifications that the employer is looking for.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

- Review the job description carefully

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Be specific and provide examples

- Practice your answers out loud

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as this shows the interviewer that you are respectful of their time.

- Wear a suit or business casual attire

- Be well-groomed

- Arrive 10-15 minutes early

4. Be Yourself and Be Enthusiastic

The interviewer wants to get to know the real you, so be yourself and let your personality shine through. It is also important to show the interviewer that you are enthusiastic about the position and the company.

- Be genuine and authentic

- Show your passion for the job

- Be positive and upbeat

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pneumatic Press Hand interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!