Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Press Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

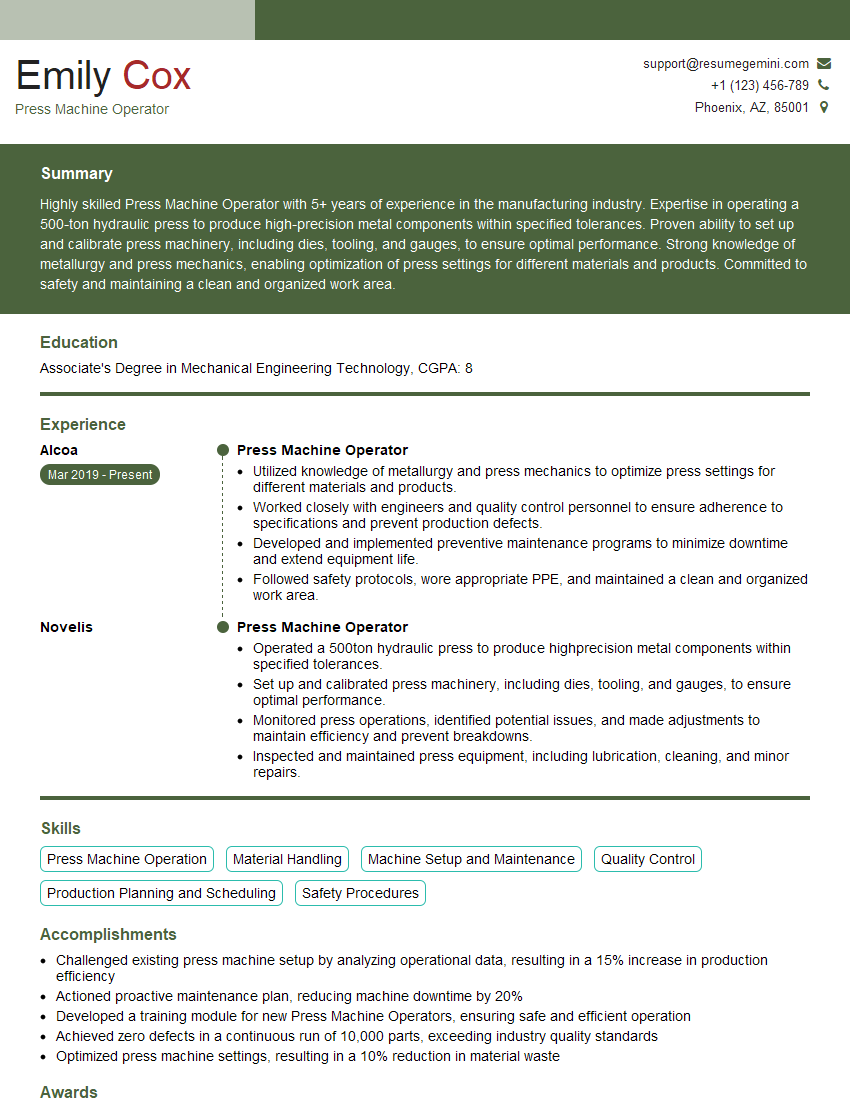

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Press Machine Operator

1. Explain the steps involved in setting up a press machine for a specific job?

To set up a press machine for a specific job, I follow these general steps:

- Read and understand the job order: I review the job order to gather information about the required part specifications, materials, and production quantity.

- Select and install the appropriate dies: Based on the part design, I choose the correct dies for the punching or forming operation and install them into the press machine.

- Adjust machine settings: I set the press parameters such as stroke length, pressure, and speed according to the job requirements and material properties.

- Load and secure the material: I carefully load the material into the machine and secure it using clamps or fixtures to ensure proper alignment and prevent movement during the pressing operation.

- Test run and fine-tuning: I perform a test run to check for any issues, such as misalignment or incorrect settings. I make necessary adjustments to optimize the machine’s performance for the job.

2. How do you maintain and troubleshoot a press machine?

Daily Maintenance

- Lubricate moving parts: I grease or oil all moving parts, such as bearings, slides, and linkages, to reduce friction and wear.

- Clean the machine: I remove any debris, metal chips, or coolant from the machine’s surface and components.

- Inspect dies and tooling: I check dies and tooling for signs of wear or damage. I clean and sharpen them as needed.

Troubleshooting

- Machine not starting: I check the power supply, fuses, and electrical connections. I also inspect the hydraulic or pneumatic system for leaks or pressure issues.

- Pressing errors: If the machine is not producing parts to the correct specifications, I analyze the machine settings, die alignment, and material quality. I make adjustments as necessary.

- Unusual noises or vibrations: I listen for any unusual sounds or vibrations that may indicate mechanical problems. I investigate the source and take corrective action.

3. What are the safety protocols that you follow when operating a press machine?

- Wear appropriate PPE: I wear safety glasses, gloves, and hearing protection when operating the press machine.

- Follow lockout/tagout procedures: I lock out and tag out the machine before performing any maintenance or repairs.

- Maintain a clean and organized work area: I keep the area around the press machine clear of clutter and debris to prevent tripping hazards.

- Never reach into the press area while it is in operation: I use long tools or other devices to adjust or remove parts from the machine.

- Be aware of pinch points and moving parts: I am always mindful of the machine’s moving components and avoid putting my hands or body in harm’s way.

4. Describe the different types of press machines and their applications?

- Mechanical press: Uses a flywheel and crank mechanism to generate the pressing force. Suitable for high-volume production of small to medium-sized parts.

- Hydraulic press: Uses hydraulic fluid to generate the pressing force. Provides precise control over force and speed, suitable for forming and bending operations.

- Pneumatic press: Uses compressed air to generate the pressing force. Offers fast cycle times and is used for light-duty applications.

- Servo press: Uses a servo motor to control the ram movement. Provides high precision and repeatability, suitable for complex forming operations.

- Transfer press: Has multiple stations that perform different operations on the workpiece as it moves through the press. Used for high-volume production of complex parts.

5. How do you ensure the quality of parts produced on a press machine?

- Set up the machine correctly: I follow established procedures to ensure proper setup and calibration of the press machine.

- Inspect materials: I check the quality of incoming materials to prevent defects from entering the production process.

- Monitor the pressing process: I observe the machine’s performance during production and make adjustments as needed to maintain consistent part quality.

- Perform regular inspections: I conduct periodic inspections of produced parts to identify any deviations from specifications.

- Follow quality control procedures: I adhere to established quality control standards and use appropriate measuring tools to ensure parts meet the required tolerances.

6. What is dwell time and how does it affect the pressing process?

Dwell time is the duration that the press ram remains at the bottom of its stroke. It allows the material to fully form or bond before the ram retracts.

Dwell time affects the part quality:

- Too short: Insufficient dwell time can result in incomplete forming or weak bonds.

- Too long: Excessive dwell time can cause material deformation or damage.

Optimizing dwell time is crucial for achieving the desired part properties.

7. Explain the difference between blanking and piercing operations?

- Blanking: A cutting operation that removes a specific shape from the sheet metal, creating a separate part.

- Piercing: A cutting operation that creates a hole in the sheet metal without removing a separate part. The material is displaced around the hole.

Both operations use different types of dies and require specific machine settings.

8. Describe the role of die clearance in the pressing process?

Die clearance is the gap between the punch and die during the pressing operation. It affects the material flow and the quality of the formed part:

- Too small: Insufficient clearance can cause excessive friction, material tearing, and increased wear on the dies.

- Too large: Excessive clearance can result in poor part accuracy, burrs, and reduced material strength.

Proper die clearance is essential for achieving optimal part quality and tool life.

9. How do you calculate the tonnage required for a press machine?

The tonnage required for a press machine depends on several factors:

- Material thickness: Thicker materials require higher tonnage.

- Material strength: Stronger materials require higher tonnage.

- Die design: Complex die designs with multiple cutting edges require higher tonnage.

- Part geometry: Parts with deep draws or sharp bends require higher tonnage.

Tonnage can be calculated using empirical formulas or software that consider these factors.

10. What are some common maintenance issues with press machines and how do you address them?

- Hydraulic leaks: Inspect hydraulic lines and fittings for leaks. Tighten connections or replace damaged components.

- Air leaks: Check pneumatic lines and connections for leaks. Replace or seal damaged components.

- Excessive vibration: Investigate the source of vibration, such as loose bolts, misaligned components, or imbalances. Tighten or replace loose parts.

- Die wear: Regularly inspect dies for wear and damage. Sharpen or replace worn dies to ensure proper cutting performance.

- Electrical faults: Check electrical connections, wiring, and components for any damage or loose connections. Contact a qualified electrician for repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Press Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Press Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Press Machine Operator, you will be responsible for the efficient and safe operation of press machines to produce high-quality products.

1. Machine Operation

Operate and monitor press machines accurately and efficiently to produce parts according to specifications.

- Set up and adjust machines for different production runs.

- Monitor machine performance and make necessary adjustments to ensure optimal operation.

2. Material Handling

Load and unload materials into and out of the press machine safely and efficiently.

- Inspect materials for defects or damage.

- Maintain a clean and organized work area.

3. Quality Control

Inspect produced parts for quality and accuracy.

- Use measuring tools and instruments to verify dimensions and tolerances.

- Identify and resolve any quality issues.

4. Maintenance

Perform basic maintenance on press machines.

- Lubricate moving parts.

- Clean and inspect machines regularly.

- Report any maintenance issues to supervisors.

Interview Tips

To prepare for your interview for a Press Machine Operator role, follow these tips:

1. Research the Company

Learn about the company’s values, mission, and products. This will demonstrate your interest in the company.

- Visit the company website.

- Read industry news and publications.

2. Prepare Your Resume and Cover Letter

Highlight your relevant experience and skills in your resume and cover letter. Use specific details to demonstrate your accomplishments.

- Use keywords from the job description.

- Proofread your documents carefully.

3. Practice Your Answers

Prepare answers to common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Use the STAR method to structure your answers.

- Use specific examples from your experience.

4. Ask Questions

Prepare questions to ask the interviewer. This shows your interest in the role and the company.

- Ask about the company’s culture.

- Ask about opportunities for advancement.

5. Dress Professionally

First impressions matter. Dress professionally for your interview to show that you respect the opportunity.

- Wear clean and pressed clothes.

- Avoid wearing casual clothing.

6. Be Punctual

Arrive on time for your interview. Punctuality shows that you value the interviewer’s time.

- Plan your route and leave yourself extra time.

- If you are running late, call the interviewer.

7. Be Confident and Enthusiastic

Project a positive and confident attitude during your interview. Show the interviewer that you are excited about the opportunity.

- Make eye contact.

- Smile and be polite.

- Use positive body language.

8. Follow Up

After your interview, send a thank-you note to the interviewer. This shows your appreciation for the opportunity.

- Reiterate your interest in the role.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Press Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!