Are you gearing up for an interview for a Rotary Shear Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rotary Shear Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

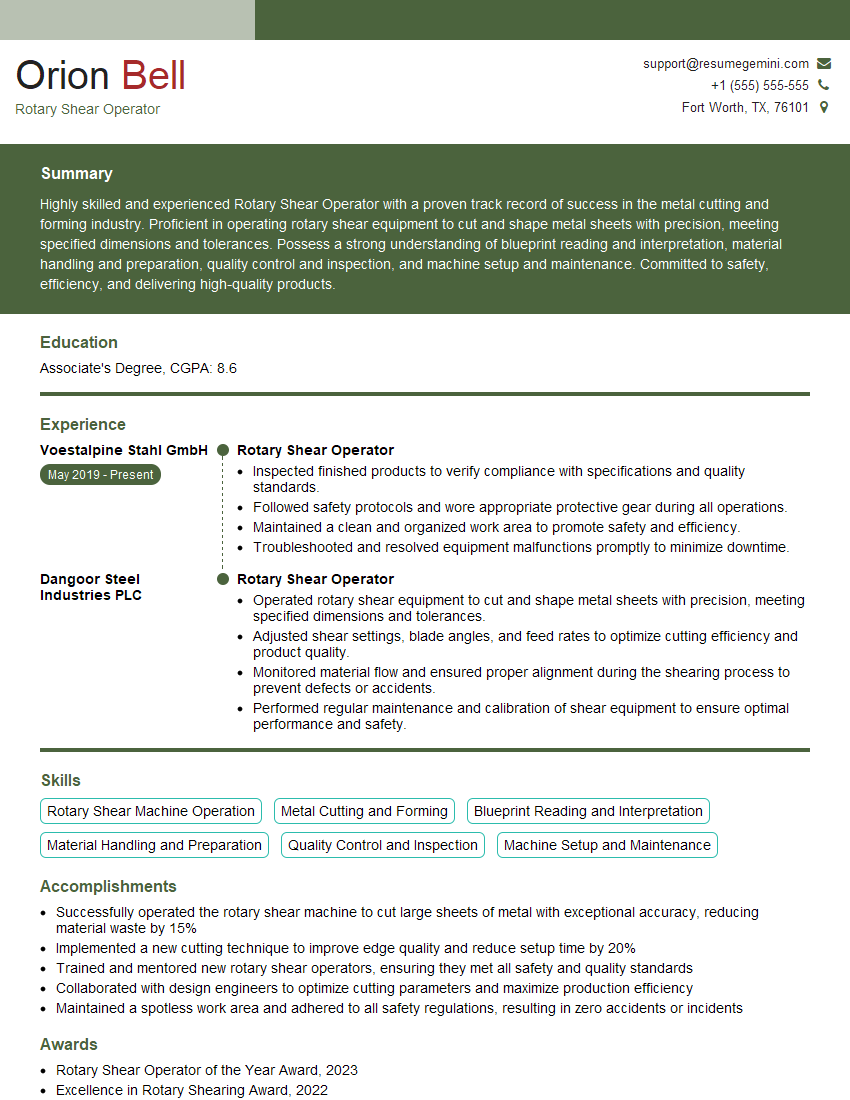

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Shear Operator

1. What are the responsibilities of a Rotary Shear Operator?

As a Rotary Shear Operator, I will be responsible for:

- Operating the rotary shear machine to cut metal sheets to the desired dimensions and shapes.

- Setting up and adjusting the machine according to the job requirements.

- Ensuring that the machine is operating safely and efficiently.

- Inspecting the finished products to ensure that they meet the specifications.

- Maintaining the machine and keeping it clean and in good working order.

2. What are the safety precautions that need to be taken when operating a Rotary Shear?

When operating a Rotary Shear, I will adhere to the following safety precautions:

Wearing appropriate personal protective equipment (PPE).

- Safety glasses

- Ear plugs

- Gloves

Ensuring that the machine is properly grounded.

Keeping the work area clean and free of debris.

Never operating the machine when it is not in good working order.

Following all lockout/tagout procedures before performing any maintenance or repairs.

3. What are the different types of Rotary Shears?

There are two main types of Rotary Shears:

- Mechanical Rotary Shears: These machines use a mechanical drive to rotate the blades.

- Hydraulic Rotary Shears: These machines use a hydraulic drive to rotate the blades.

Each type of shear has its own advantages and disadvantages. Mechanical shears are generally less expensive and easier to maintain, while hydraulic shears are more powerful and can cut thicker materials.

4. What are the factors that affect the cutting quality of a Rotary Shear?

The following factors affect the cutting quality of a Rotary Shear:

- Blade sharpness: Dull blades will produce ragged cuts.

- Blade clearance: The clearance between the blades affects the cut quality and the thickness of the material that can be cut.

- Material thickness: Thicker materials require more force to cut, which can affect the cut quality.

- Machine speed: The speed of the machine can affect the cut quality, with higher speeds producing smoother cuts.

5. How do you troubleshoot a Rotary Shear that is not cutting properly?

If a Rotary Shear is not cutting properly, the following steps can be taken to troubleshoot the issue:

- Check the blades for sharpness and proper clearance.

- Check the material thickness to ensure that it is within the machine’s capacity.

- Check the machine speed and adjust it if necessary.

- Check the hydraulic system for leaks or other problems.

- Check the electrical system for loose connections or other problems.

6. What is the difference between a Rotary Shear and a Guillotine Shear?

A Rotary Shear and a Guillotine Shear are both used to cut metal sheets, but they operate in different ways.

A Rotary Shear uses a rotating blade to cut the metal sheet, while a Guillotine Shear uses a straight blade that moves up and down to cut the metal sheet.

Rotary Shears are generally faster and more efficient than Guillotine Shears, but they can only cut straight lines.

Guillotine Shears can cut both straight lines and curves, but they are slower and less efficient than Rotary Shears.

7. What are the maintenance requirements for a Rotary Shear?

The maintenance requirements for a Rotary Shear include:

- Regularly cleaning and lubricating the machine.

- Inspecting the blades for sharpness and proper clearance.

- Checking the hydraulic system for leaks or other problems.

- Checking the electrical system for loose connections or other problems.

8. What are the safety features of a Rotary Shear?

The safety features of a Rotary Shear include:

- A blade guard to protect the operator’s hands.

- A foot pedal to operate the machine, which keeps the operator’s hands away from the blades.

- An emergency stop button to stop the machine immediately in case of an emergency.

9. What is the maximum thickness of material that a Rotary Shear can cut?

The maximum thickness of material that a Rotary Shear can cut depends on the model of the machine and the type of material being cut.

In general, Rotary Shears can cut materials up to 1/2 inch thick.

10. What are the advantages of using a Rotary Shear?

The advantages of using a Rotary Shear include:

- High speed and efficiency.

- Ability to cut straight lines and curves.

- Reduced operator fatigue.

- Improved safety features.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Shear Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Shear Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Rotary Shear Operator, you will be responsible for a diverse range of duties, including:

1. Machine Operation

Operate Rotary Shear machines to cut and shape metal sheets according to specifications.

- Set up and calibrate Rotary Shear machines based on production requirements.

- Load and feed metal sheets into the machine, ensuring proper alignment and positioning.

- Monitor machine performance and make adjustments as needed to optimize efficiency.

2. Quality Control

Inspect finished products to ensure they meet quality standards.

- Verify product dimensions, shape, and surface finish against specifications.

- Identify and rectify defects, ensuring production of high-quality products.

3. Safety and Maintenance

Follow established safety procedures and maintain a safe work environment.

- Adhere to all safety regulations and guidelines for operating Rotary Shear machines.

- Inspect machines regularly, identify potential issues, and perform basic machine maintenance.

- Report any safety hazards or machine problems to supervisors promptly.

4. Production Optimization

Contribute to production efficiency by identifying and implementing improvements.

- Analyze production processes and suggest modifications to enhance efficiency.

- Collaborate with other team members to identify and resolve production bottlenecks.

- Stay informed about industry best practices and implement them to improve operations.

Interview Tips

To prepare for a Rotary Shear Operator interview effectively, it’s crucial to:

1. Research the Company and Position

Learn about the company’s culture, values, and products. Understand the specific requirements of the Rotary Shear Operator position and how your skills and experience align with them.

2. Practice Answering Common Interview Questions

Prepare for questions related to your technical skills, such as your experience operating Rotary Shear machines, quality control measures, and safety procedures. Also, practice behavioral questions that explore your teamwork, problem-solving, and communication abilities.

Example Outline of questions can be:

- Tell me about your experience operating Rotary Shear machines.

- Describe a time when you identified and resolved a production issue.

- How do you ensure the quality of products produced using the Rotary Shear?

3. Highlight Your Relevant Skills and Experience

Emphasize your proficiency in operating Rotary Shear machines and your understanding of the industry. Showcase your attention to detail, problem-solving abilities, and commitment to safety. Quantify your accomplishments with specific examples to demonstrate your impact.

- For example, you could mention a time when you implemented a new technique that improved production efficiency by 15%.

4. Be Enthusiastic and Confident

Convey your passion for the role and your eagerness to contribute to the team’s success. Express your confidence in your abilities and your willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Shear Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!