Feeling lost in a sea of interview questions? Landed that dream interview for Sinter Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sinter Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

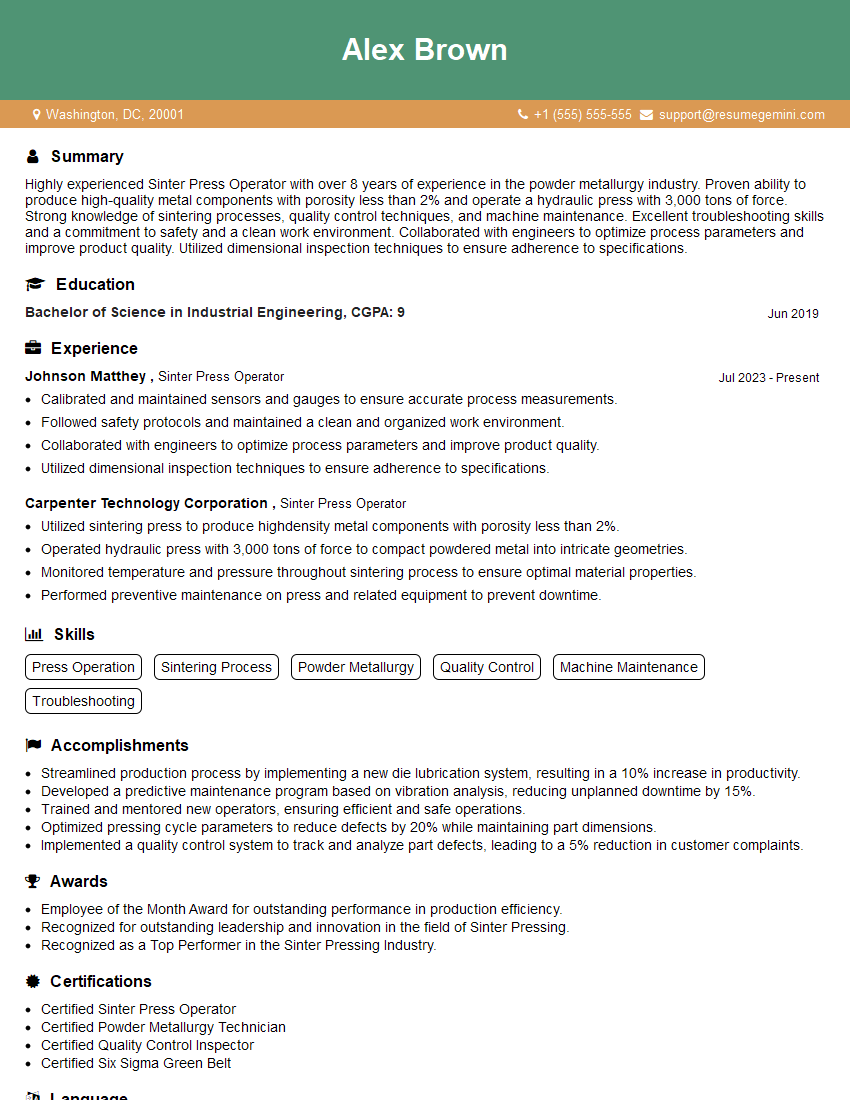

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sinter Press Operator

1. Describe the process of sinter pressing?

Sinter pressing is a metalworking process that involves compacting powdered metal into a solid form. The process is carried out in a press, which applies high pressure to the powder, causing the particles to bond together. Sinter pressing is used to produce a wide range of metal products, including gears, bearings, and cutting tools.

2. What are the different types of sinter presses?

Hydraulic Presses

- Hydraulic presses use a hydraulic cylinder to generate the pressure required for sintering.

- They are capable of producing high pressures, which makes them suitable for compacting hard materials.

Mechanical Presses

- Mechanical presses use a mechanical linkage to generate the pressure required for sintering.

- They are less expensive than hydraulic presses, but they are not capable of producing as high pressures.

3. What are the key factors that affect the quality of sintered parts?

The quality of sintered parts is affected by a number of factors, including the following:

- Powder composition

- Particle size

- Pressure

- Temperature

- Sintering time

4. What are the common defects that can occur in sintered parts?

The common defects that can occur in sintered parts include the following:

- Porosity

- Cracking

- Delamination

- Distortion

- Oxidation

5. How can defects in sintered parts be prevented?

Defects in sintered parts can be prevented by carefully controlling the process parameters and by using high-quality materials.

- Using the correct powder composition and particle size

- Applying the correct pressure and temperature

- Sintering for the correct amount of time

- Using a protective atmosphere to prevent oxidation

6. What are the advantages of sinter pressing over other metalworking processes?

Sinter pressing offers a number of advantages over other metalworking processes, including the following:

- It can be used to produce complex shapes

- It is a cost-effective process

- It produces parts with high strength and density

- It is a versatile process that can be used to produce a wide range of materials

7. What are the applications of sinter pressing?

Sinter pressing is used to produce a wide range of metal products, including the following:

- Gears

- Bearings

- Cutting tools

- Electrical contacts

- Magnetic materials

8. What are the challenges of sinter pressing?

The challenges of sinter pressing include the following:

- Controlling the quality of the sintered parts

- Preventing defects

- Scaling up the process to produce high volumes of parts

9. What are the future trends in sinter pressing?

The future trends in sinter pressing include the following:

- The development of new materials and processes

- The increased use of automation

- The integration of sinter pressing with other manufacturing processes

10. What is your experience with sinter pressing?

I have been working as a Sinter Press Operator for the past 5 years. In this role, I have been responsible for the following tasks:

- Operating sinter presses

- Maintaining and repairing sinter presses

- Inspecting sintered parts

- Developing and implementing process improvements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sinter Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sinter Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sinter press operators are responsible for operating and maintaining sinter presses used in the production of metal parts. They ensure that the presses are operating efficiently and safely, and that the parts produced meet the required specifications.

1. Set up and operate sinter press

Sinter press operators set up and operate sinter presses by following established procedures.

- Load the press with the correct amount of powder.

- Position the dies correctly.

- Set the press pressure and temperature.

- Start the press cycle.

2. Monitor press operation

Sinter press operators monitor the press operation to ensure that it is running smoothly and that the parts are being produced to the correct specifications. They check the press pressure and temperature, and make adjustments as necessary.

- Check the parts for defects.

- Unload the press and clean the dies.

3. Maintain press equipment

Sinter press operators maintain the press equipment by performing regular cleaning and lubrication. They also inspect the press for signs of wear and tear, and make repairs as necessary.

- Follow established maintenance procedures.

- Identify and troubleshoot problems.

- Keep records of maintenance activities.

4. Work with other team members

Sinter press operators work with other team members, such as engineers and quality control inspectors, to ensure that the parts produced meet the required specifications.

- Communicate with other team members.

- Participate in problem-solving activities.

- Follow safety procedures.

Interview Tips

To ace your interview for a sinter press operator position, it is important to prepare thoroughly. Here are some tips to help you succeed:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company website.

- Read the job description carefully.

- Talk to people who work for the company, if possible.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Be enthusiastic and positive.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Dress in a way that makes you feel confident.

- Avoid wearing clothes that are too revealing or too casual.

- Make sure your clothes are clean and wrinkle-free.

4. Be on time

Punctuality is important, so be sure to arrive for your interview on time. If you are running late, call the interviewer to let them know.

- Plan your route in advance.

- Leave yourself extra time for traffic and parking.

- If you are running late, call the interviewer as soon as possible.

5. Be confident

Confidence is key in an interview. Believe in yourself and your abilities, and let the interviewer know that you are the right person for the job.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be enthusiastic about the position.

Next Step:

Now that you’re armed with the knowledge of Sinter Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sinter Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini