Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spring Coiling Machine Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

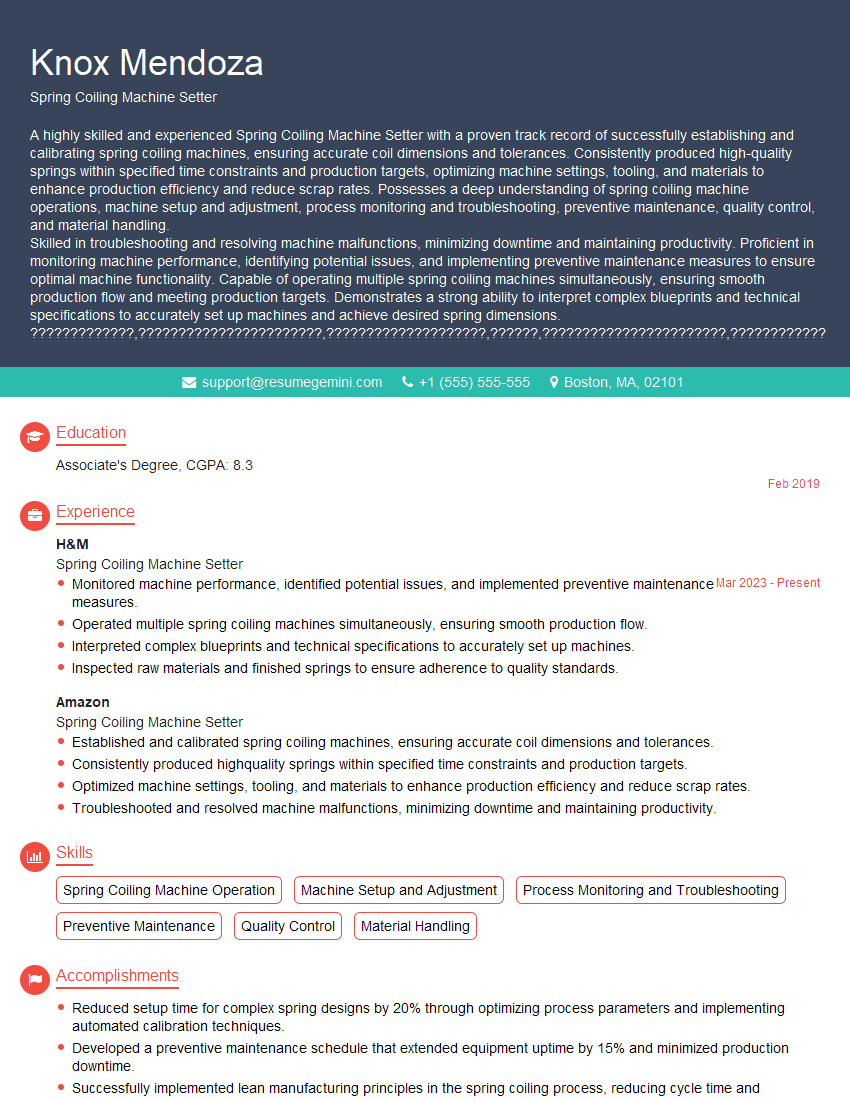

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spring Coiling Machine Setter

1. What are the key components of a spring coiling machine?

The key components of a spring coiling machine include:

- Wire feeding system

- Coiling head

- Cutter

- Control system

- Safety features

2. What are the different types of spring coiling machines?

CNC Spring Coiling Machines

- Computer Numerical Control (CNC) spring coiling machines use computer programs to control the coiling process.

- CNC machines offer high precision and repeatability.

- They can produce complex spring shapes and coils with varying diameters and pitches.

Mechanical Spring Coiling Machines

- Mechanical spring coiling machines use cams and gears to control the coiling process.

- They are typically less expensive than CNC machines.

- However, they offer less precision and flexibility.

3. What are the factors that affect the quality of a spring?

The factors that affect the quality of a spring include:

- Material properties

- Spring design

- Coiling process parameters

- Heat treatment

- Surface finish

4. What are the common problems that can occur during spring coiling?

The common problems that can occur during spring coiling include:

- Wire breakage

- Spring distortion

- Coiling errors

- Machine downtime

5. How do you troubleshoot and resolve spring coiling problems?

To troubleshoot and resolve spring coiling problems, I would first identify the symptoms of the problem.

- Then, I would check the machine settings and make sure that they are correct.

- Next, I would check the wire and make sure that it is of the correct size and material.

- Finally, I would check the coiling head and make sure that it is properly adjusted.

6. How do you set up a spring coiling machine?

To set up a spring coiling machine, I would first follow the manufacturer’s instructions.

- I would then make sure that the machine is properly leveled and calibrated.

- Next, I would install the correct tooling for the type of spring that I want to produce.

- Finally, I would set the machine parameters, such as the wire feed rate, the coiling speed, and the pitch.

7. How do you maintain a spring coiling machine?

To maintain a spring coiling machine, I would regularly clean and lubricate all of the moving parts.

- I would also check the machine for any signs of wear or damage.

- If I find any problems, I would repair them immediately.

- In addition, I would keep a maintenance log to track all of the maintenance that I perform on the machine.

8. What are the safety precautions that you take when operating a spring coiling machine?

When operating a spring coiling machine, I always wear safety glasses, gloves, and earplugs.

- I also make sure that the machine is properly guarded and that all of the safety devices are working properly.

- I never operate the machine when I am tired or under the influence of alcohol or drugs.

- In addition, I always follow the manufacturer’s safety instructions.

9. What are the quality control procedures that you follow when producing springs?

To ensure the quality of the springs that I produce, I follow a number of quality control procedures.

- I first inspect the raw materials to make sure that they meet the specifications.

- I then check the machine settings to make sure that they are correct.

- Next, I inspect the springs during the coiling process to make sure that they are meeting the desired specifications.

- Finally, I inspect the finished springs to make sure that they meet all of the customer’s requirements.

10. What are your career goals?

My career goal is to become a skilled and experienced spring coiling machine setter.

- I want to learn as much as I can about the spring coiling process and the different types of springs that can be produced.

- I also want to develop my skills in troubleshooting and resolving spring coiling problems.

- Ultimately, I want to be able to produce high-quality springs that meet the needs of my customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spring Coiling Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spring Coiling Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spring Coiling Machine Setter is responsible for setting up and operating a spring coiling machine to produce precision springs. Their primary duties include:

1. Machine Setup and Operation

Setting up the machine according to specifications, including wire diameter, pitch, and number of coils

- Operating the machine to produce springs within the specified tolerances

- Monitoring the machine’s operation and making necessary adjustments to maintain quality and productivity

2. Troubleshooting and Maintenance

Identifying and resolving machine malfunctions and breakdowns

- Performing routine maintenance procedures to keep the machine in good working condition

3. Quality Control

Inspecting finished springs to ensure they meet specifications

- Using measuring equipment and gauges to check dimensions, tolerances, and surface quality

- Rejecting non-conforming springs and maintaining quality records

4. Production Support

Assisting with material handling, coil loading, and other production tasks

- Working with other team members to ensure a smooth production process

Interview Tips

Preparing for an interview for a Spring Coiling Machine Setter position requires a comprehensive approach. Here are some tips to help you ace the interview:

1. Research the Company and Position

Learn about the company’s history, products, and industry standing. Understanding the specific requirements of the Spring Coiling Machine Setter role will help you tailor your answers to the interviewer’s expectations.

- Visit the company’s website and read any available information about their products and services.

- Review job descriptions and industry publications to gain insights into the responsibilities and skills required for the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in machine setup, operation, and maintenance. Quantify your experience by providing specific examples of how you have successfully set up, operated, and maintained spring coiling machines in previous roles.

- Describe your expertise in setting up machines according to specifications, including wire diameter, pitch, and number of coils.

- Provide examples of troubleshooting and resolving machine malfunctions, demonstrating your ability to identify and rectify issues efficiently.

3. Demonstrate Quality Consciousness

Showcase your commitment to quality by highlighting your experience in inspecting finished springs and maintaining quality records. Explain your understanding of industry standards and your dedication to producing products that meet customer specifications.

- Describe your experience in using measuring equipment and gauges to check dimensions, tolerances, and surface quality.

- Explain your understanding of the importance of rejecting non-conforming springs and maintaining accurate quality records.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Anticipate questions about your experience, skills, and motivation for the role. Consider using the STAR (Situation, Task, Action, Result) method to structure your responses and provide specific examples of your accomplishments.

- Prepare for questions about your experience in setting up and operating spring coiling machines, as well as your troubleshooting and maintenance skills.

- Practice describing your approach to quality control and your commitment to producing high-quality products.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview on time to demonstrate your respect for the interviewer and the company. Prepare copies of your resume and any relevant documents to share with the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Spring Coiling Machine Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.