Are you gearing up for an interview for a Stamping Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Stamping Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

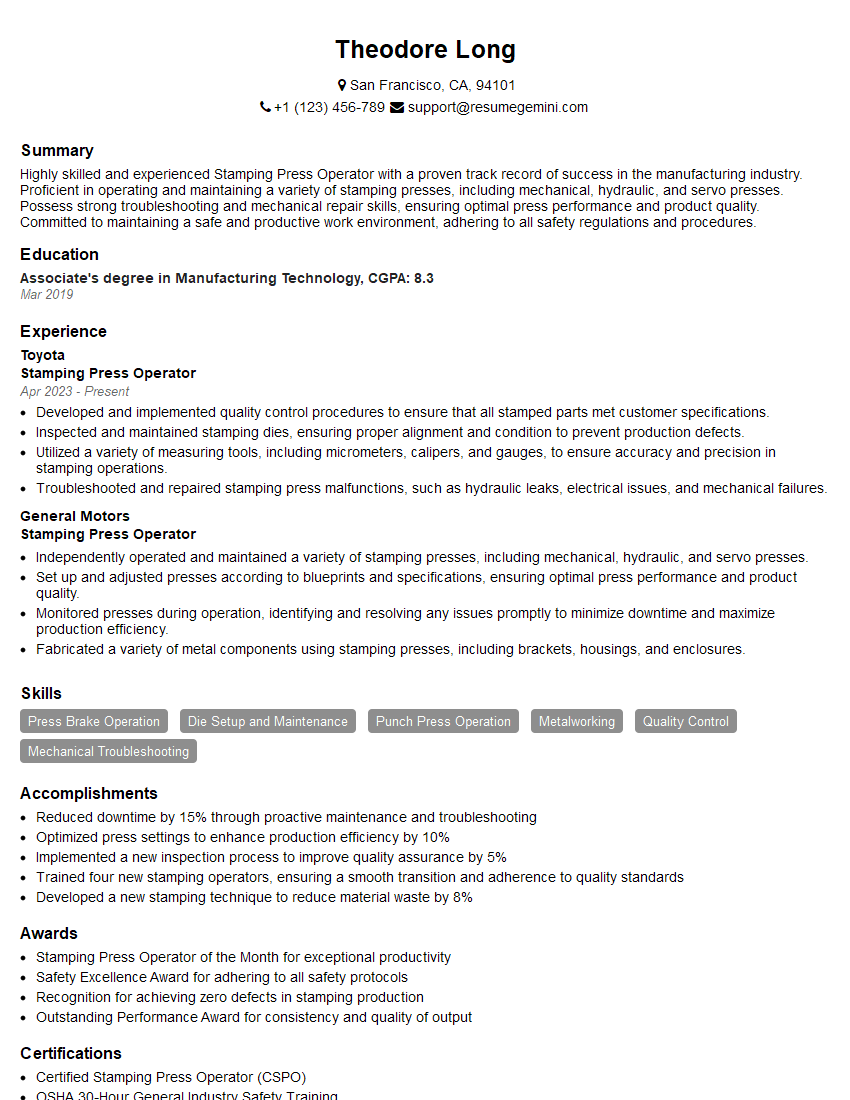

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stamping Press Operator

1. What are the key safety precautions that you follow when operating a stamping press?

- Always wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Inspect the press and tooling before each use to ensure they are in good working order.

- Never place your hands or fingers near the die area while the press is in operation.

- Keep the work area clean and free of debris.

- Follow all lockout/tagout procedures.

2. What are the different types of stamping presses and what are their advantages and disadvantages?

Mechanical Presses

- Advantages: High speed, high precision, durable.

- Disadvantages: Noisy, require regular maintenance.

Hydraulic Presses

- Advantages: Powerful, accurate, less noisy than mechanical presses.

- Disadvantages: Slower speed, higher cost.

Pneumatic Presses

- Advantages: Small, lightweight, quiet, can be used in hazardous environments.

- Disadvantages: Lower force, less precise than other types of presses.

3. What is the purpose of a die in a stamping press and what are some of the different types of dies?

A die is a tool used to shape and cut metal in a stamping press. There are many different types of dies, including:

- Blanking dies: Cut out a shape from a sheet of metal.

- Piercing dies: Create holes in a sheet of metal.

- Forming dies: Bend or shape a sheet of metal into a desired form.

- Progressive dies: Perform multiple operations on a sheet of metal in a single stroke of the press.

4. What are the key factors that affect the quality of a stamped part?

- Material properties of the metal being stamped.

- Condition of the die and press.

- Process parameters, such as speed, pressure, and dwell time.

- Operator skill.

- Environmental conditions.

5. What is the difference between a blanking die and a piercing die?

- Blanking die: Cuts out a shape from a sheet of metal, leaving a clean edge.

- Piercing die: Creates holes in a sheet of metal, leaving a rough edge.

6. What are some of the common problems that can occur when operating a stamping press and how can they be prevented?

- Misfeeds: Can be prevented by ensuring that the material is properly aligned and fed into the press.

- Die wear: Can be prevented by regularly inspecting and maintaining the die.

- Part breakage: Can be prevented by using the correct material and process parameters.

- Operator error: Can be prevented by providing proper training and supervision.

7. What is the importance of preventative maintenance for a stamping press?

- Prevents breakdowns and costly repairs.

- Extends the life of the press and tooling.

- Ensures the safety of the operator.

- Improves the quality of stamped parts.

8. What are some of the latest advancements in stamping press technology?

- Electric presses: More energy-efficient and quieter than traditional mechanical presses.

- Servo presses: Provide greater control over the stamping process.

- Automated die changing systems: Reduce setup time and improve productivity.

9. What is your experience with troubleshooting and repairing stamping presses?

- Describe specific troubleshooting and repair procedures that you have performed.

- Explain how you diagnosed the problem and how you resolved it.

10. What is your experience with setting up and operating stamping presses?

- Describe the steps involved in setting up and operating a stamping press.

- Explain how you ensure that the press is properly calibrated and adjusted.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stamping Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stamping Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stamping Press Operators are responsible for the operation and maintenance of stamping presses, which are used to cut, shape, and form metal parts. They work in a variety of industries, including automotive, aerospace, and electronics.

1. Operating Stamping Presses

Operate stamping presses to cut, shape, and form metal parts according to specifications.

- Load and unload metal blanks into the press.

- Adjust press settings to achieve the desired results.

- Monitor the press operation and make adjustments as needed.

2. Maintaining Stamping Presses

Perform preventive maintenance on stamping presses to ensure optimal performance.

- Lubricate moving parts.

- Inspect and replace worn or damaged parts.

- Calibrate the press to ensure accuracy.

3. Troubleshooting Stamping Press Problems

Troubleshoot and resolve problems with stamping presses.

- Identify the source of the problem.

- Make repairs or adjustments as needed.

- Restart the press and verify that the problem has been resolved.

4. Quality Control

Inspect stamped parts to ensure that they meet quality standards.

- Check for defects such as cracks, burrs, and scratches.

- Reject parts that do not meet specifications.

- Maintain records of quality control inspections.

Interview Tips

Preparing for an interview for a Stamping Press Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a Stamping Press Operator.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work in the industry.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples from your own experience.

- Tailor your answers to the specific job you’re applying for.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience as a Stamping Press Operator. Be prepared to talk about your skills, knowledge, and accomplishments.

- Highlight your experience operating stamping presses.

- Describe your knowledge of metalworking and stamping processes.

- Share examples of how you’ve solved problems on the job.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Wear clean, pressed clothes.

- Arrive for your interview 10-15 minutes early.

- Be polite and respectful to everyone you meet.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Stamping Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.