Are you gearing up for an interview for a Straightening Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Straightening Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

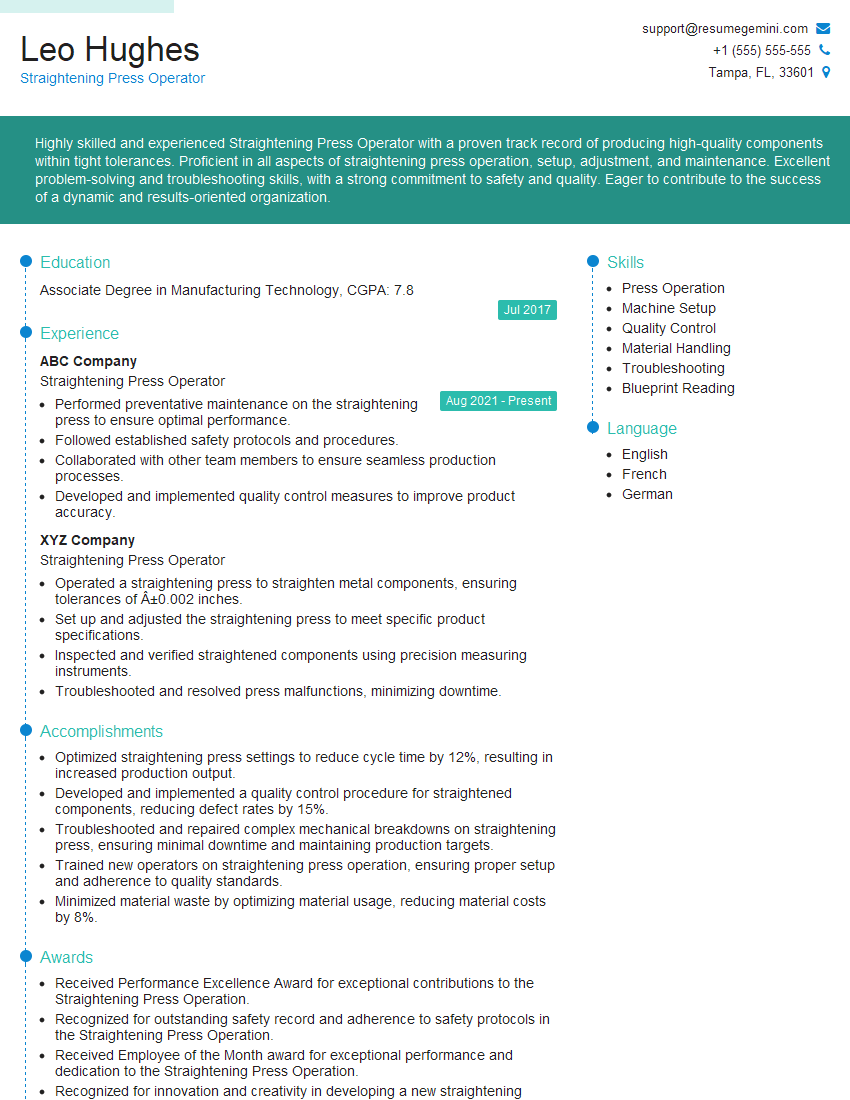

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Straightening Press Operator

1. What are the key responsibilities of a Straightening Press Operator?

As a Straightening Press Operator, my responsibilities include:

- Setting up and operating straightening presses to straighten and align metal parts.

- Determining the appropriate straightening process and tooling for the job.

- Monitoring the straightening process to ensure it meets specifications.

- Inspecting finished parts to ensure they meet quality standards.

- Maintaining and troubleshooting straightening presses to ensure optimal performance.

2. How do you ensure that the parts are straightened within the specified tolerances?

Using Precision Measuring Instruments

- Employing precision measuring instruments like dial indicators or micrometers to accurately measure the dimensions and alignment of parts.

- Comparing measurements to specifications to assess compliance.

Adjusting Machine Settings

- Fine-tuning straightening press settings based on the material properties and required tolerances.

- Making incremental adjustments to achieve precise straightening.

Monitoring Process Variables

- Continuously monitoring key process variables such as pressure, temperature, and speed.

- Adjusting settings as needed to maintain optimal conditions for straightening.

3. What are the different types of straightening presses and their applications?

Here are the main types of straightening presses and their typical applications:

- Hydraulic Press: Uses hydraulic pressure for straightening operations, suitable for heavy-duty parts.

- Mechanical Press: Employs a mechanical linkage to apply straightening force, ideal for smaller and intricate parts.

- Manual Press: Operated by hand, used for light-duty or small-scale straightening tasks.

- CNC Press: Computer-controlled for precise and automated straightening, capable of handling complex parts.

4. Can you describe the maintenance procedures you would perform on a straightening press?

Regularly performing the following maintenance procedures is critical for optimal press operation:

- Daily Inspection: Checking for any visible damage, leaks, or loose components.

- Weekly Lubrication: Greasing moving parts and bearings to minimize friction and wear.

- Monthly Inspection: Thorough examination of press components, including hydraulic hoses, valves, and electrical connections.

- Annual Maintenance: Comprehensive check and calibration of the press, including replacement of worn or damaged parts.

5. What precautions should be taken when operating a straightening press?

Ensuring safety when operating a straightening press requires adhering to these precautions:

- Wear appropriate PPE: Always wear safety glasses, hearing protection, and gloves.

- Secure workpieces: Ensure parts are securely clamped or held to prevent movement during straightening.

- Avoid overloading: Never exceed the machine’s rated capacity to prevent damage or injury.

- Stay clear of moving parts: Keep hands and body away from the straightening area while the press is operating.

- Follow lockout/tagout procedures: Isolate the press from power before performing maintenance or repairs.

6. How do you troubleshoot common problems with a straightening press?

Common problems with straightening presses and their troubleshooting steps include:

- Insufficient straightening force: Check hydraulic pressure, adjust settings, or inspect for blockages.

- Uneven straightening: Examine dies for wear or misalignment, adjust pressure, or check workpiece placement.

- Excessive noise or vibration: Inspect bearings for wear or lubrication, check alignment, or balance the machine.

- Leaks: Identify the source of the leak, tighten connections or replace seals, and check hydraulic hoses for damage.

7. What are the different materials that can be straightened using a straightening press?

A straightening press can handle various materials, including:

- Metals: Steel, aluminum, copper, brass

- Plastics: ABS, PVC, polycarbonate

- Composites: Fiberglass, carbon fiber

- Wood: Plywood, lumber

8. How do you maintain the accuracy and calibration of a straightening press?

Maintaining accuracy and calibration involves:

- Regular Inspection: Periodically check for any changes in performance or alignment.

- Calibration: Use precision measuring instruments to calibrate the press against known standards.

- Die Maintenance: Inspect and replace worn or damaged dies to ensure consistent straightening.

- Software Updates: Apply manufacturer-recommended software updates to maintain optimal press performance.

9. Describe the process of setting up a straightening press for a new job.

Setting up a straightening press for a new job typically involves:

- Reviewing specifications: Understanding the required tolerances and dimensions.

- Selecting dies: Choosing the appropriate dies based on material and part geometry.

- Setting machine parameters: Adjusting pressure, speed, and other settings as per job requirements.

- Loading and securing workpiece: Placing the part in the press and ensuring it is securely held.

- Testing and adjustments: Performing trial runs and fine-tuning settings to achieve desired results.

10. Explain the role of die design in the straightening process.

Die design plays a crucial role in the straightening process:

- Matching part profile: Dies are designed to match the shape and dimensions of the part being straightened.

- Applying pressure: Dies apply pressure to the part to force it into the desired shape.

- Controlling deformation: Dies limit the deformation of the part, ensuring it meets required tolerances.

- Material compatibility: Dies are made of materials compatible with the part being straightened to prevent damage or contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Straightening Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Straightening Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Straightening Press Operators are responsible for operating straightening presses to correct defects and ensure the dimensional accuracy of metal parts.

1. Operating Straightening Presses

The operator is responsible for setting up and operating straightening presses to correct defects in metal parts, such as bends, twists, and warpage.

- Set up and adjust straightening presses according to part specifications

- Load and unload metal parts from the press

- Monitor the straightening process and make adjustments as needed

2. Inspecting Metal Parts

The operator is responsible for inspecting metal parts before and after straightening to ensure that they meet quality standards.

- Visually inspect metal parts for defects

- Use measuring tools to verify the dimensional accuracy of metal parts

- Identify and report any defects to the supervisor

3. Maintaining Equipment

The operator is responsible for maintaining the straightening press and related equipment to ensure optimal performance.

- Clean and lubricate the straightening press

- Inspect the straightening press for wear and tear

- Perform minor repairs and maintenance tasks

4. Following Safety Procedures

The operator is responsible for following all safety procedures to ensure a safe work environment.

- Wear appropriate personal protective equipment

- Follow lockout/tagout procedures

- Report any unsafe conditions to the supervisor

Interview Tips

To prepare for an interview for a Straightening Press Operator position, it is important to understand the key responsibilities of the role and to be able to demonstrate your skills and experience in these areas.

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their products or services, history, and mission statement.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method to answer behavioral questions.

- Prepare specific examples of your skills and experience that are relevant to the job.

3. Be Prepared to Discuss Your Experience

The interviewer will want to know about your experience as a Straightening Press Operator. Be prepared to discuss your skills and experience in the following areas:

- Operating straightening presses

- Inspecting metal parts

- Maintaining equipment

- Following safety procedures

4. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional throughout the interview. Dress appropriately, arrive on time, and make eye contact with the interviewer.

- Be yourself and let your personality shine through.

- Be honest and upfront about your skills and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Straightening Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.