Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Swaging Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

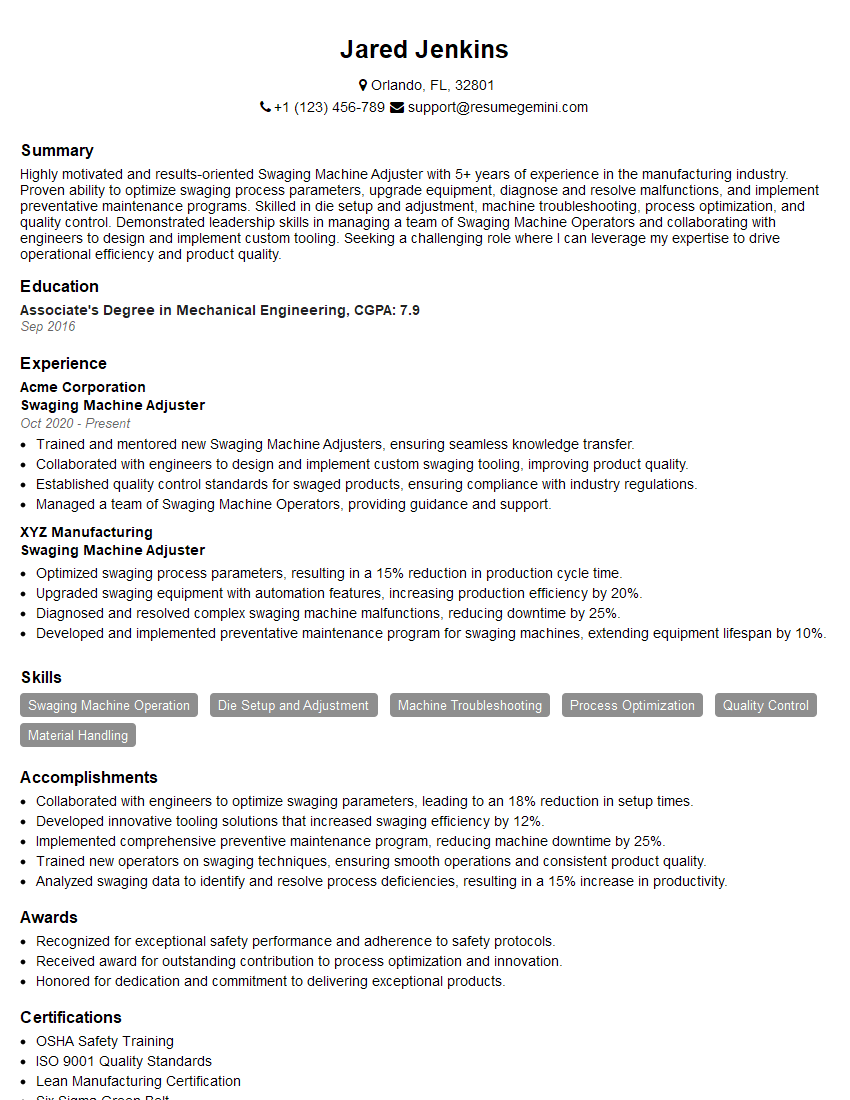

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swaging Machine Adjuster

1. What are the different types of swaging machines and what are their applications?

- Rotary swaging machines: These machines are used for high-volume production of small, precision parts. They are capable of producing a wide variety of shapes, including round, square, hexagonal, and oval.

- Linear swaging machines: These machines are used for producing larger parts, such as those used in the automotive and aerospace industries. They are capable of producing complex shapes, such as splines, gears, and threads.

- Orbital swaging machines: These machines are used for producing parts that require a high degree of precision. They are capable of producing parts with very tight tolerances.

2. What are the key factors to consider when setting up a swaging machine?

Factors related to the swaging process

- Type of swaging machine

- Material properties

- Part geometry

- Production volume

Factors related to the swaging tooling

- Die design

- Die material

- Die lubrication

3. How do you troubleshoot common problems that occur during swaging?

- Poor surface finish: This can be caused by a variety of factors, including incorrect die design, improper lubrication, or excessive wear on the dies.

- Dimensional errors: This can be caused by incorrect machine setup, worn dies, or material defects.

- Cracking or breaking of the workpiece: This can be caused by excessive force, improper material selection, or defects in the workpiece.

4. What are the safety precautions that need to be taken when operating a swaging machine?

- Always wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Never operate a swaging machine that is not properly guarded.

- Never place your hands or any other body parts near the dies while the machine is operating.

- Keep the work area clean and free of debris.

- Follow all manufacturer’s instructions for safe operation.

5. What are the latest trends in swaging technology?

- The use of advanced materials, such as carbide and ceramic, for dies and tooling.

- The development of new swaging processes, such as orbital swaging and rotary swaging.

- The use of automation and robotics to improve productivity and quality.

- The development of new software to simulate the swaging process and optimize machine settings.

6. What is the difference between swaging and forging?

- Swaging: A metal forming process in which a workpiece is shaped by hammering or pressing it between two dies.

- Forging: A metal forming process in which a workpiece is shaped by heating it and then hammering or pressing it into a mold.

7. What are the advantages of swaging over other metal forming processes?

- High precision

- Good surface finish

- Low tooling costs

- High production rates

8. What are the challenges of swaging?

- Tooling can be complex and expensive to manufacture.

- The process can be slow compared to other metal forming processes.

- The process can generate a lot of noise and vibration.

9. What is your experience with swaging machines?

- I have been working as a swaging machine adjuster for the past 5 years.

- I have experience with a variety of swaging machines, including rotary, linear, and orbital swaging machines.

- I am proficient in setting up and operating swaging machines to produce high-quality parts.

- I have a strong understanding of the swaging process and the factors that affect part quality.

10. Why are you interested in this position?

- I am interested in this position because I am passionate about the swaging process and I am always looking for ways to improve my skills.

- I am confident that I have the skills and experience that you are looking for in a swaging machine adjuster.

- I am eager to learn more about the swaging process and to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swaging Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swaging Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Swaging Machine Adjuster is responsible for calibrating, adjusting, and maintaining swaging machines to ensure they function optimally in the production process. Below are the critical job responsibilities of a Swaging Machine Adjuster:

1. Setup and Calibration

Sets up and calibrates swaging machines as per specifications, including setting up dies, feed mechanisms, and cutting devices.

2. Machine Maintenance

Performs regular maintenance checks on swaging machines, including lubrication, cleaning, and inspection of components to prevent breakdowns and ensure smooth operation.

3. Adjustments and Troubleshooting

Adjusts machine settings to optimize performance, such as feed rate, pressure, and temperature. Troubleshoots and resolves issues with swaging machines to minimize downtime and maintain production efficiency.

4. Quality Control

Monitors the quality of swaged products to ensure they meet specifications and standards. Identifies and corrects defects in products or processes to maintain high-quality output.

5. Training and Supervision

May train and supervise other operators on the proper use and maintenance of swaging machines, ensuring they follow safety guidelines and standard operating procedures.

Interview Tips

To ace an interview for a Swaging Machine Adjuster position, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Industry

Research the company you’re applying to and the industry in which they operate. Understand their products, services, and business goals to demonstrate your interest and knowledge.

2. Highlight Relevant Experience

Emphasize your experience in setting up, calibrating, and maintaining swaging machines. Quantify your accomplishments and provide specific examples of your contributions.

3. Technical Skills

Demonstrate your understanding of swaging machine components, such as dies, feed mechanisms, and cutting devices. Explain your ability to troubleshoot and resolve common issues.

4. Safety and Quality

Stress your commitment to safety and quality control. Describe your experience in following safety guidelines and maintaining high-quality output.

5. Problem-Solving Abilities

Highlight your problem-solving abilities and give examples of how you’ve identified and resolved issues with swaging machines. Explain your approach to troubleshooting and finding solutions.

6. Communication and Teamwork

Describe your communication and teamwork skills. Explain how you effectively interact with colleagues, supervisors, and customers to ensure smooth operations.

Next Step:

Now that you’re armed with the knowledge of Swaging Machine Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Swaging Machine Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini