Are you gearing up for a career in Swage Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Swage Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

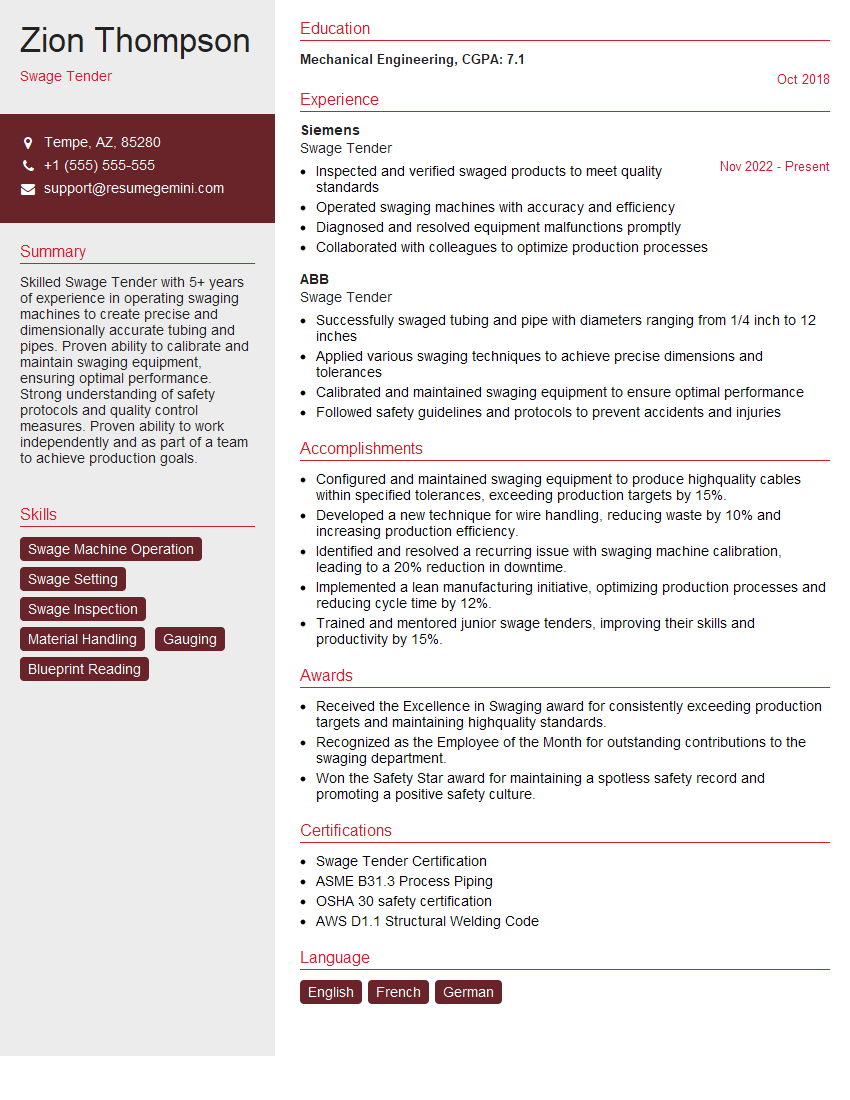

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Swage Tender

1. How do you determine the correct swaging die size for a given wire material and insulation type?

To determine the correct swaging die size, I consider the following factors:

- Wire material: Different materials have different tensile strengths and compression characteristics, affecting the swaging process.

- Insulation type: The thickness and hardness of the insulation can influence the die size required to achieve proper swaging without damaging the wire.

- Wire diameter: The wire diameter must be within the specified range for the die size to ensure a tight and secure connection.

- Required connection strength: The die size should be selected to provide adequate swaging force to meet the desired connection strength.

2. What are the key parameters to control during the swaging process to ensure high-quality connections?

Process variables

- Swaging force: Optimizing the swaging force is crucial to achieve a secure connection without damaging the wire or insulation.

- Swaging time: Controlling the swaging time ensures that the connection is formed properly without excessive deformation.

- Die alignment: Proper alignment of the swaging dies is essential for accurate and consistent swaging.

Material properties

- Tensile strength of wire: The wire’s tensile strength influences the amount of force required for proper swaging.

- Hardness of insulation: Harder insulation requires higher swaging force to achieve a secure connection.

3. How do you troubleshoot common swaging defects, such as loose connections, stripped insulation, or wire breakage?

- Loose connections: Inspect the die size and alignment. Adjust the swaging force or time as needed.

- Stripped insulation: Check the die condition and ensure proper insulation thickness. Adjust the swaging force or time accordingly.

- Wire breakage: Examine the wire material and tensile strength. Adjust the swaging force or time to reduce stress on the wire.

4. What maintenance procedures are essential for prolonging the life of swaging machinery?

- Regular cleaning: Remove dirt, debris, and metal shavings from the dies and swaging machine to prevent wear and damage.

- Die inspection: Periodically inspect the dies for wear, damage, or misalignment and replace them as needed.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to reduce friction and wear.

- Calibration: Calibrate the swaging machine regularly to ensure accuracy and consistency in the swaging process.

5. How do you handle variations in wire materials and insulation types to ensure consistent swaging results?

- Evaluate material properties: Determine the tensile strength and insulation hardness of different materials to select appropriate swaging parameters.

- Adjust swaging settings: Modify the swaging force, time, or die size based on the material properties to achieve optimal connections.

- Test and verify results: Conduct pull tests or other quality control measures to ensure that the swaged connections meet the required specifications.

6. What are the safety precautions to observe when operating swaging machinery?

- Wear appropriate PPE: Use eye protection, gloves, and safety shoes to mitigate potential hazards.

- Guard against pinch points: Be aware of moving parts and keep hands away from potential pinch points.

- Secure workpieces: Ensure that the wire and insulation are securely held in place before swaging.

- Follow lockout/tagout procedures: Perform maintenance or repairs only after isolating the machine from power sources.

7. How do you optimize the swaging process to minimize waste and maximize productivity?

- Proper setup: Ensure accurate die alignment and optimize swaging parameters to reduce the likelihood of rejects.

- Automated feeding: Implement automated wire and insulation feeding systems to increase efficiency and reduce manual labor.

- Quality control: Implement automated quality control measures, such as pull testing or vision inspection, to identify and eliminate defective connections.

- Preventive maintenance: Regularly maintain the swaging machinery to minimize downtime and prevent unexpected failures.

8. What are the latest advancements in swaging technology that you are familiar with?

- Ultrasonic swaging: Ultrasonic vibrations enhance the swaging process, reducing force requirements and improving connection quality.

- Laser swaging: Laser technology provides precise and localized heating, enabling swaging without damaging adjacent components.

- Smart swaging machines: Advanced machines incorporate sensors and data analysis to optimize swaging parameters and monitor process quality.

9. How do you stay updated with the latest industry best practices and technological developments in swaging?

- Attend industry conferences and workshops: Participate in industry events and seminars to learn about new technologies and trends.

- Read technical journals and articles: Stay informed about advancements in the field through technical literature.

- Network with industry professionals: Connect with other swage tenders and engineers to share knowledge and experiences.

10. What is your approach to continuous improvement in your role as a Swage Tender?

- Identify areas for improvement: Regularly assess the swaging process and identify areas where efficiency or quality can be enhanced.

- Research and implement solutions: Explore new techniques, technologies, or materials to improve swaging operations.

- Monitor and evaluate results: Track the implementation of improvement measures and evaluate their effectiveness through data analysis.

- Share knowledge and best practices: Collaborate with colleagues to share successful improvement strategies and promote a culture of continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Swage Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Swage Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Swage Tenders are responsible for the operation of swaging machines, which are used to form, shape, or join metal parts or wires. They must have a strong understanding of the swaging process and the different types of swaging machines available. Key job responsibilities include:

1. Machine Operation

Swage Tenders are responsible for setting up, operating, and maintaining swaging machines. They must be able to follow detailed instructions and ensure that the machines are operating safely and efficiently.

- Sets up and operates swaging machines to form, shape, or join metal parts or wires.

- Adjusts machine settings, such as pressure, temperature, and speed, to ensure optimal performance.

2. Quality Control

Swage Tenders are responsible for inspecting the quality of the parts produced by the swaging machines. They must be able to identify defects and take corrective action.

- Inspects parts produced by swaging machines to ensure they meet specifications.

- Identifies defects and takes corrective action, such as adjusting machine settings or replacing worn dies.

3. Die Maintenance

Swage Tenders are responsible for maintaining the dies used in the swaging machines. They must be able to clean, sharpen, and replace dies as needed.

- Cleans, sharpens, and replaces dies used in swaging machines.

- Maintains a clean and organized work area.

4. Safety

Swage Tenders must be aware of the safety hazards associated with operating swaging machines. They must follow all safety procedures and wear appropriate personal protective equipment.

- Follows all safety procedures and wears appropriate personal protective equipment.

- Reports any unsafe conditions to a supervisor.

Interview Tips

Preparing for an interview for a Swage Tender position can be daunting, but there are some tips that you can follow to increase your chances of success.

1. Research the Company and the Position

Take the time to learn about the company and the specific position you are applying for. This will help you to understand the company’s culture and the skills and experience that they are looking for.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and identify the key skills and experience that the company is looking for.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you should start practicing your answers to common interview questions. This will help you to feel more confident and prepared during the actual interview.

- Think about your strengths and weaknesses and how they relate to the job requirements.

- Prepare examples of your work experience that demonstrate your skills and abilities.

3. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the culture.

- Ask about the company’s plans for growth and expansion.

- Ask about the company’s commitment to safety.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual attire.

- Dress in a suit or business casual attire.

- Make sure your clothes are clean and pressed.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Swage Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Swage Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.