Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trim Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

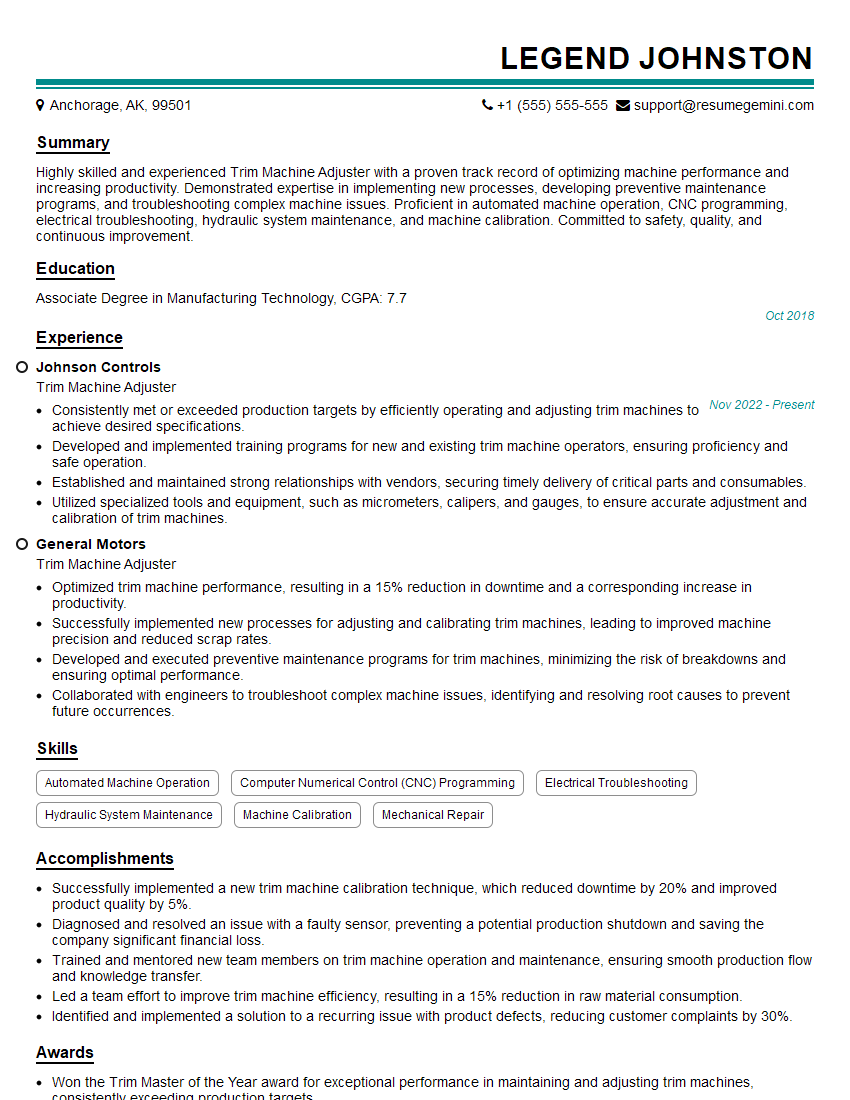

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trim Machine Adjuster

1. Explain the process of setting up and calibrating a trim machine?

Sample Answer:

- Mount the trim machine on a stable surface and connect it to the power supply.

- Load the material to be trimmed into the input hopper.

- Set the desired trim parameters, such as the trim width, speed, and depth.

- Calibrate the machine’s sensors to ensure accurate trimming.

- Run a test trim to verify that the machine is functioning properly.

2. How do you troubleshoot common trim machine problems?

Sample Answer:

Problem: Material is not being trimmed properly

- Check the trim blades for wear or damage.

- Ensure that the material is properly loaded into the hopper.

- Adjust the trim parameters to ensure they are appropriate for the material.

Problem: Machine is overheating

- Check the ventilation system to ensure it is clear of obstructions.

- Clean the machine of any dust or debris that may be blocking airflow.

- Ensure that the machine is not overloaded.

3. How do you maintain a trim machine to ensure optimal performance?

Sample Answer:

- Clean the machine regularly to remove dust and debris.

- Inspect the trim blades regularly for wear or damage and replace them as needed.

- Check the machine’s calibration regularly and adjust as necessary.

- Follow the manufacturer’s recommended maintenance schedule.

4. What safety precautions should be taken when operating a trim machine?

Sample Answer:

- Wear proper safety gear, including safety glasses, gloves, and earplugs.

- Never operate the machine with the safety guards removed.

- Keep hands and fingers away from moving parts.

- Do not overload the machine.

5. How do you handle and store trim waste safely?

Sample Answer:

- Dispose of trim waste in designated containers.

- Keep trim waste areas clean and free of debris.

- Follow the manufacturer’s recommendations for handling and storing trim waste.

- Wear proper safety gear when handling trim waste.

6. What is the difference between a reciprocating and a rotary trim machine?

Sample Answer:

- Reciprocating trim machines use a back-and-forth motion to trim materials.

- Rotary trim machines use a spinning blade to trim materials.

- Reciprocating trim machines are typically used for thicker materials, while rotary trim machines are typically used for thinner materials.

7. What materials can be trimmed using a trim machine?

Sample Answer:

- Leather

- Fabric

- Paper

- Plastic

- Wood

8. What are the benefits of using a trim machine?

Sample Answer:

- Increased productivity

- Improved accuracy

- Reduced labor costs

- Increased safety

9. What are the latest trends in trim machine technology?

Sample Answer:

- Automated trim machines

- Laser trim machines

- Waterjet trim machines

10. How would you improve the efficiency of a trim machine process?

Sample Answer:

- Use automated trim machines to reduce labor costs.

- Implement lean manufacturing principles to reduce waste and improve productivity.

- Train operators on proper machine operation and maintenance.

- Use high-quality materials to reduce the need for rework.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trim Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trim Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

Trim Machine Adjusters oversee the operation and maintenance of trim machines used in manufacturing processes. Their primary responsibilities include:

1. Machine Operation and Adjustment:

Adjust, calibrate, and maintain trim machines to ensure optimal performance and production efficiency.

- Determine appropriate machine settings based on product specifications and material properties.

- Monitor and inspect machine performance, identify potential issues, and make necessary adjustments.

2. Quality Control:

Inspect finished products for compliance with quality standards and specifications.

- Detect and correct any defects or inaccuracies in the trimmed materials.

- Collaborate with Quality Control personnel to ensure adherence to quality requirements.

3. Process Optimization:

Continuously monitor and evaluate trim machine processes to identify areas for improvement.

- Analyze production data to identify bottlenecks and inefficiencies.

- Recommend process adjustments to increase productivity and minimize waste.

4. Maintenance and Troubleshooting:

Perform routine maintenance and troubleshooting to keep trim machines operating smoothly.

- Lubricate, clean, and inspect machine components regularly.

- Identify and resolve mechanical or electrical issues promptly to minimize downtime.

Interview Preparation Tips:

To ace your Trim Machine Adjuster interview, consider the following tips:

1. Research the Industry:

Gain a thorough understanding of the manufacturing industry, particularly the processes and equipment used in trimming operations.

- Read industry publications and attend trade shows to stay updated on the latest developments.

- Research specific trim machine manufacturers and models to demonstrate your knowledge.

2. Highlight Your Technical Skills:

Emphasize your expertise in mechanical adjustment, troubleshooting, and quality control techniques.

- Provide specific examples of how you have used your skills to improve production efficiency or reduce downtime.

- Explain your understanding of the principles of trim machines, including blade types and cutting mechanisms.

3. Demonstrate Your Problem-Solving Abilities:

Interviewers will be interested in your ability to identify and resolve issues quickly and effectively.

- Describe a situation where you encountered a problem with a trim machine and how you approached the solution.

- Explain your process for analyzing problems, evaluating potential causes, and implementing corrective actions.

4. Showcase Your Attention to Detail:

Trim Machine Adjusters must have a keen eye for detail to ensure precision trimming and minimize waste.

- Provide examples of your ability to inspect products thoroughly and identify even minor defects.

- Discuss your commitment to accuracy and compliance with quality standards.

5. Communicate Effectively:

Prepare to articulate your technical knowledge and findings clearly and concisely to both supervisors and team members.

- Practice describing complex technical concepts to non-technical audiences.

- Demonstrate your ability to listen actively, ask clarifying questions, and communicate solutions effectively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trim Machine Adjuster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.