Are you gearing up for an interview for a Billet Driller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Billet Driller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

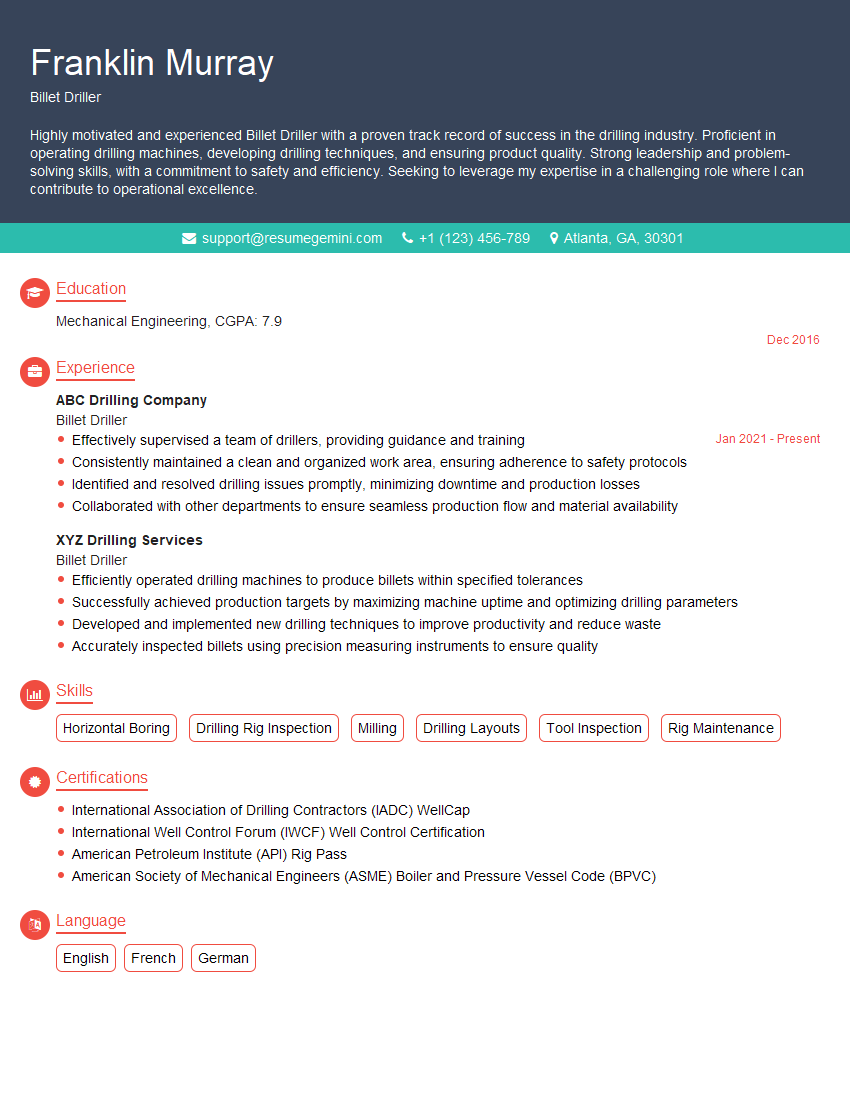

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Billet Driller

1. What are the different types of billet drilling machines?

There are various types of billet drilling machines, commonly used are:

- Radial Arm Drilling Machine

- Upright Drilling Machine

- Gang Drilling Machine

- CNC Drilling Machine

- Portable Drilling Machine

2. What are the safety precautions to be taken while operating a billet drilling machine?

Ensure Proper Machine Setup:

- Inspect the machine before operation for any damage or defects.

- Secure the billet properly on the worktable to prevent movement.

Use Appropriate Tools and PPE:

- Select the correct drill bit size and type for the material and hole diameter.

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

Maintain Safe Operating Practices:

- Operate the machine at recommended speeds and feeds to avoid overheating or damage.

- Never leave the machine unattended while it is running.

3. How do you determine the correct drill bit size for a given hole diameter?

The recommended drill bit size is typically slightly smaller than the desired hole diameter. You can use a drill bit size chart or consult the material manufacturer’s guidelines to determine the appropriate drill bit size for your specific application.

4. What factors influence the drilling speed and feed rate?

The drilling speed and feed rate are influenced by several factors, including:

- Material hardness and machinability

- Drill bit size and type

- Machine capabilities

- Desired hole quality and accuracy

5. How do you ensure the accuracy and quality of the drilled holes?

- Properly align the workpiece and secure it firmly to the worktable.

- Use sharp and high-quality drill bits to minimize burrs and ensure hole precision.

- Follow recommended drilling parameters (speed, feed, depth) for the given material and drill bit size.

- Inspect the drilled holes visually or using measuring instruments to ensure they meet the specified tolerances.

6. How do you troubleshoot common problems encountered during billet drilling?

Common problems during billet drilling can include:

- Broken drill bits: Incorrect drill bit selection, excessive feed rate, or improper workpiece clamping.

- Overheating: Excessive drilling speed, dull drill bits, or insufficient lubrication.

- Poor hole quality: Incorrect drill bit size, misalignment of workpiece, or worn-out drill bit.

- Chattering: Misalignment of drill bit, incorrect drilling speed, or excessive workpiece vibration.

7. What types of cutting fluids are used in billet drilling and why?

Cutting fluids are used in billet drilling to:

- Lubricate the drill bit and workpiece, reducing friction and heat generation.

- Cool the workpiece and drill bit, preventing overheating and premature tool wear.

- Flush away chips and debris, improving hole quality and extending drill bit life.

Common types of cutting fluids include:

- Mineral oils

- Synthetic oils

- Water-soluble coolants

- Semi-synthetic fluids

8. How do you calculate the drilling depth based on the workpiece thickness?

To calculate the drilling depth for a given workpiece thickness, you need to consider the following parameters:

- Desired hole depth

- Thickness of the workpiece

- Drill bit length

- Drill chuck travel

Formula: Drilling Depth = Desired Hole Depth + (Workpiece Thickness / 2) – (Drill Chuck Travel / 2)

9. What is the purpose of a pilot hole in billet drilling?

A pilot hole is a small-diameter hole drilled before the main drilling operation. It serves several purposes:

- Provides guidance for the main drill bit, ensuring a more accurate and straight hole.

- Reduces the load on the main drill bit, extending its lifespan.

- Prevents the drill bit from wandering or breaking, especially when drilling into hard or thick materials.

10. How do you maintain and calibrate a billet drilling machine to ensure optimal performance?

- Regularly clean and lubricate the machine components to prevent wear and tear.

- Inspect drill bits for sharpness and replace as needed to ensure efficient drilling.

- Check and adjust the alignment of the drill bit and workpiece to maintain accuracy.

- Calibrate the machine periodically using reference gauges or precision measuring tools to ensure accurate hole dimensions and positioning.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Billet Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Billet Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Billet Drillers are responsible for using specialized equipment to create holes in metal billets. Billets are large, solid blocks of metal that are used to create a variety of products, such as automobile parts and construction materials. Billet Drillers must have a high level of precision and accuracy in their work, as even small errors can cause the billet to be scrapped.

1. Set up and operate drilling equipment.

Billet Drillers must be able to set up and operate a variety of drilling equipment, including radial drills, milling machines, and CNC (computer numerically controlled) machines. They must also be able to read and interpret blueprints and other technical drawings.

2. Drill holes in metal billets.

Billet Drillers use specialized drill bits to create holes in metal billets. They must be able to control the speed and feed of the drill bit, and they must be able to make accurate holes in a variety of materials.

3. Inspect drilled holes.

Billet Drillers must inspect drilled holes to ensure that they meet the required specifications. They must be able to identify and correct any errors, and they must be able to document their findings.

4. Maintain drilling equipment.

Billet Drillers are responsible for maintaining their drilling equipment. They must be able to perform basic maintenance tasks, such as cleaning, lubrication, and troubleshooting. They must also be able to identify and report any major problems to their supervisor.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position.

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about the position.

2. Practice answering common interview questions.

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can feel confident and prepared during your interview.

3. Dress professionally.

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for the office environment.

4. Be on time.

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be prepared to ask questions.

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. Be prepared to ask thoughtful questions that show that you are interested in the position and that you have done your research.

Next Step:

Now that you’re armed with the knowledge of Billet Driller interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Billet Driller positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini