Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bore Mill Operator for Plastic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

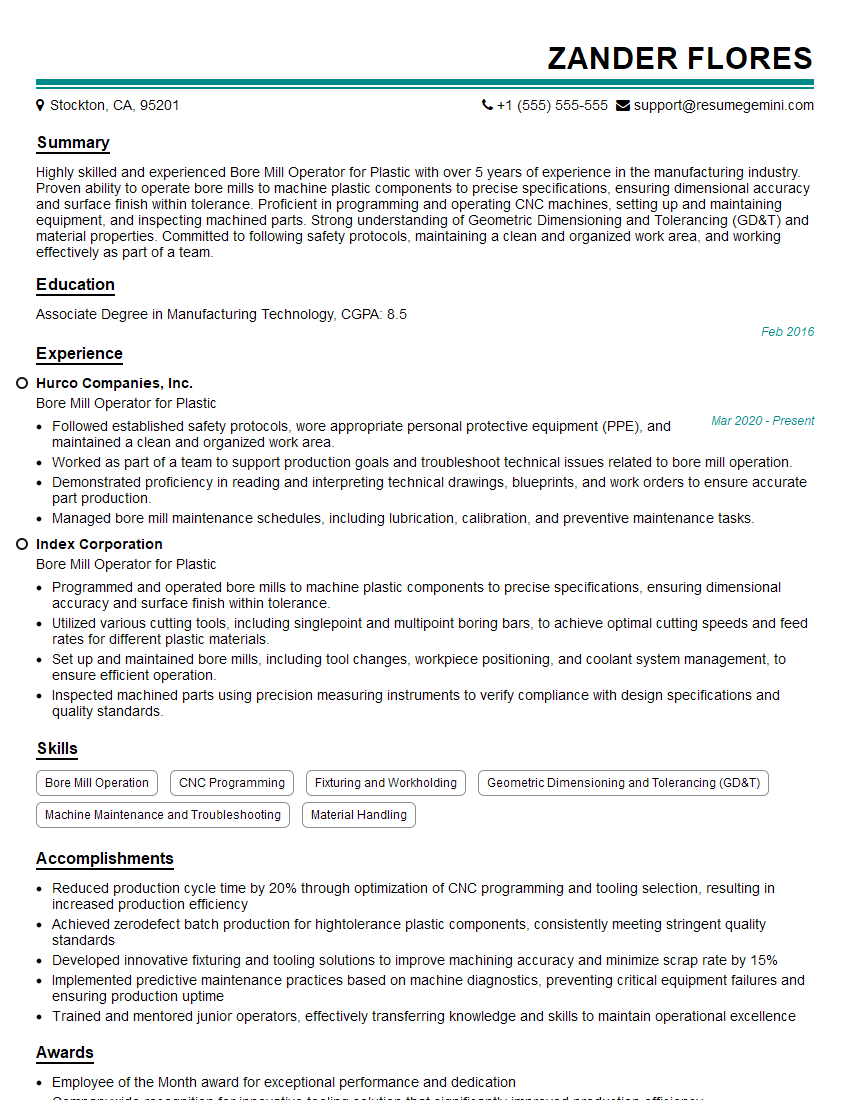

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bore Mill Operator for Plastic

1. Explain the process of setting up a bore mill machine for plastic?

The process involves several steps:

- Secure the workpiece: Place the plastic workpiece on the machine’s table and clamp it securely to prevent movement.

- Mount the cutting tool: Select the appropriate cutting tool for the bore size and material. Install it in the machine’s spindle and ensure its proper alignment.

- Set the cutting parameters: Determine the spindle speed, feed rate, and depth of cut based on the plastic material and the desired bore dimensions.

- Establish the datum point: Set the machine’s coordinate system and establish a datum point for precise positioning of the cutting tool.

- Program the machine: Input the cutting path and other parameters into the machine’s control system to guide its operation.

2. What are the common types of cutting tools used in bore milling plastic?

- Carbide inserts: Known for their hardness, durability, and ability to produce precise and smooth bores.

- High-speed steel (HSS) end mills: Versatile and cost-effective option for smaller bore diameters and less demanding applications.

- Solid carbide end mills: Provide excellent cutting performance, high precision, and extended tool life.

- Diamond-coated tools: Used for machining abrasive plastics or achieving extremely precise and high-quality bores.

3. How do you ensure the accuracy and precision of the bored holes?

Accuracy and precision are crucial:

- Use precision tooling: Employ high-quality cutting tools with accurate dimensions and sharp cutting edges.

- Calibrate the machine: Ensure the machine’s axes and spindle are calibrated regularly to maintain accuracy.

- Check tool offsets: Verify the tool offsets and positioning before starting the machining process.

- Monitor the cutting process: Observe the cutting process closely and make adjustments as needed to maintain accuracy and prevent errors.

- Use measuring instruments: Utilize precision measuring instruments such as micrometers or bore gauges to inspect the finished bores and ensure they meet the required tolerances.

4. What are the different types of plastics commonly machined using a bore mill?

- Polyethylene (PE): High-density and low-density plastics with good chemical resistance and machinability.

- Polypropylene (PP): High strength and rigidity, excellent for automotive and industrial applications.

- Polyvinyl chloride (PVC): Durable and versatile plastic with good resistance to chemicals and weather.

- Acrylic (PMMA): Clear and lightweight plastic with high impact resistance and good optical properties.

- Acetal (POM): Strong and wear-resistant plastic with low friction and high dimensional stability.

5. How do you handle and prevent common issues that arise when bore milling plastic?

- Chattering: Ensure proper tool selection, sharp cutting edges, and optimal cutting parameters to minimize vibrations and chattering.

- Burr formation: Use sharp cutting tools, adjust the feed rate and spindle speed, and consider applying a lubricant to reduce burr formation.

- Melting and distortion: Choose cutting tools and parameters that minimize heat generation and employ cooling methods such as mist lubrication or flood cooling.

- Tool wear: Monitor tool wear regularly and replace tools as necessary to maintain cutting efficiency and prevent damage to the workpiece.

- Accuracy deviations: Regularly calibrate the machine, use precision tooling, and check tool offsets to ensure accuracy and prevent deviations from the desired bore dimensions.

6. How do you optimize the cutting parameters for different types of plastics?

Optimization is essential:

- Spindle speed: Adjust based on the material hardness, tool diameter, and desired surface finish.

- Feed rate: Determine the optimal feed rate to balance cutting efficiency with tool life and surface quality.

- Depth of cut: Consider the material thickness, tool strength, and desired bore depth to avoid excessive tool wear or workpiece damage.

- Lubrication: Employ appropriate lubricants or cutting fluids to reduce friction, improve tool life, and enhance surface finish.

7. What safety precautions should be taken when operating a bore mill?

- Wear proper safety gear: Safety glasses, gloves, and appropriate clothing to protect against flying debris and rotating machinery.

- Ensure proper machine guarding: Verify that all guards and safety devices are in place and functioning correctly.

- Follow lockout/tagout procedures: De-energize the machine before performing any maintenance or adjustments.

- Maintain a clean work area: Keep the work area free of debris and tripping hazards to prevent accidents.

- Be aware of moving parts: Pay attention to the movement of the cutting tool and other machine components to avoid contact injuries.

8. How do you maintain and clean a bore mill machine?

Maintenance and cleaning are crucial:

- Regular lubrication: Lubricate moving parts and components according to the manufacturer’s recommendations.

- Cleaning the machine: Remove chips, debris, and coolant from the machine surfaces to prevent contamination and ensure smooth operation.

- Inspecting and replacing components: Regularly inspect and replace worn or damaged components, such as belts, filters, and cutting tools.

- Calibrating the machine: Calibrate the machine’s axes and spindle periodically to maintain accuracy and precision.

- Following manufacturer’s guidelines: Adhere to the manufacturer’s maintenance and cleaning instructions for specific procedures and schedules.

9. Can you describe how you troubleshoot common problems that may occur during bore milling?

- Tool breakage: Check for proper tool selection, cutting parameters, and workpiece securement.

- Poor surface finish: Adjust cutting parameters, check for tool wear, and inspect workpiece material for defects.

- Dimensional inaccuracies: Verify machine calibration, tool offsets, and cutting parameters.

- Excessive vibrations: Ensure proper tool balance, adjust cutting parameters, and check for machine resonance.

- Coolant issues: Check coolant levels, flow rate, and cleanliness to prevent overheating and cutting tool damage.

10. What is your approach to continuous improvement in bore milling operations?

- Process monitoring: Track and analyze cutting parameters, tool wear, and workpiece quality to identify areas for improvement.

- Tooling optimization: Evaluate different cutting tools, coatings, and geometries to enhance cutting efficiency and surface finish.

- Cycle time reduction: Review cutting parameters, toolpath strategies, and machine settings to optimize cycle times while maintaining quality.

- Knowledge sharing and training: Engage with colleagues and attend industry events to stay updated on best practices and technological advancements.

- Collaboration with other departments: Work closely with design and engineering teams to optimize part design and reduce the need for rework or adjustments during bore milling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bore Mill Operator for Plastic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bore Mill Operator for Plastic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bore Mill Operators for Plastic play a crucial role in the manufacturing industry by operating and maintaining bore mills to produce high-precision plastic components. Their responsibilities encompass various aspects of bore milling, including:

1. Machine Operation

Operate bore mills to machine plastic components according to specifications.

- Set up and adjust bore mills for specific machining operations.

- Load and unload plastic workpieces onto the bore mill.

2. Cutting Tool Management

Select and install appropriate cutting tools for different plastic materials and machining operations.

- Monitor cutting tool performance and make adjustments as needed.

- Sharpen or replace cutting tools to ensure optimal cutting performance.

3. Quality Control

Inspect machined components for quality and accuracy.

- Use measuring instruments to verify dimensions and tolerances.

- Identify and correct any defects or inconsistencies in the machining process.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on bore mills.

- Lubricate and clean machines to maintain optimal performance.

- Diagnose and resolve technical issues with bore mills.

Interview Tips

Preparing thoroughly for an interview as a Bore Mill Operator for Plastic can significantly increase your chances of making a positive impression and securing the job. Here are some tips and tricks to help you ace your interview:

1. Research the Company and Role

Research the company’s background, mission, and values to demonstrate your interest and understanding of their goals. Familiarize yourself with the specific responsibilities and requirements of the Bore Mill Operator role.

- Visit the company’s website, LinkedIn page, and industry news articles.

- Read the job description carefully and identify the key skills and experience the company is seeking.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in operating bore mills, handling plastic materials, and maintaining precision machining equipment. Quantify your accomplishments and provide specific examples of your work.

- Describe your experience with different types of bore mills and the materials you have machined.

- Showcase your ability to achieve tight tolerances and meet quality standards.

3. Demonstrate Problem-Solving Abilities

Interviewers look for candidates who can think critically and solve problems effectively. Prepare examples of situations where you identified and resolved issues related to bore milling or other manufacturing processes.

- Share an instance where you diagnosed and fixed a technical problem with a bore mill.

- Describe how you improved the efficiency or accuracy of a machining operation.

4. Prepare Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare questions related to the company’s growth plans, industry trends, or the specific challenges of the Bore Mill Operator position.

- Inquire about the company’s investment in new technologies or expansion plans.

- Ask about the opportunities for professional development and career advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bore Mill Operator for Plastic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bore Mill Operator for Plastic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.