Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drill Press Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drill Press Tender so you can tailor your answers to impress potential employers.

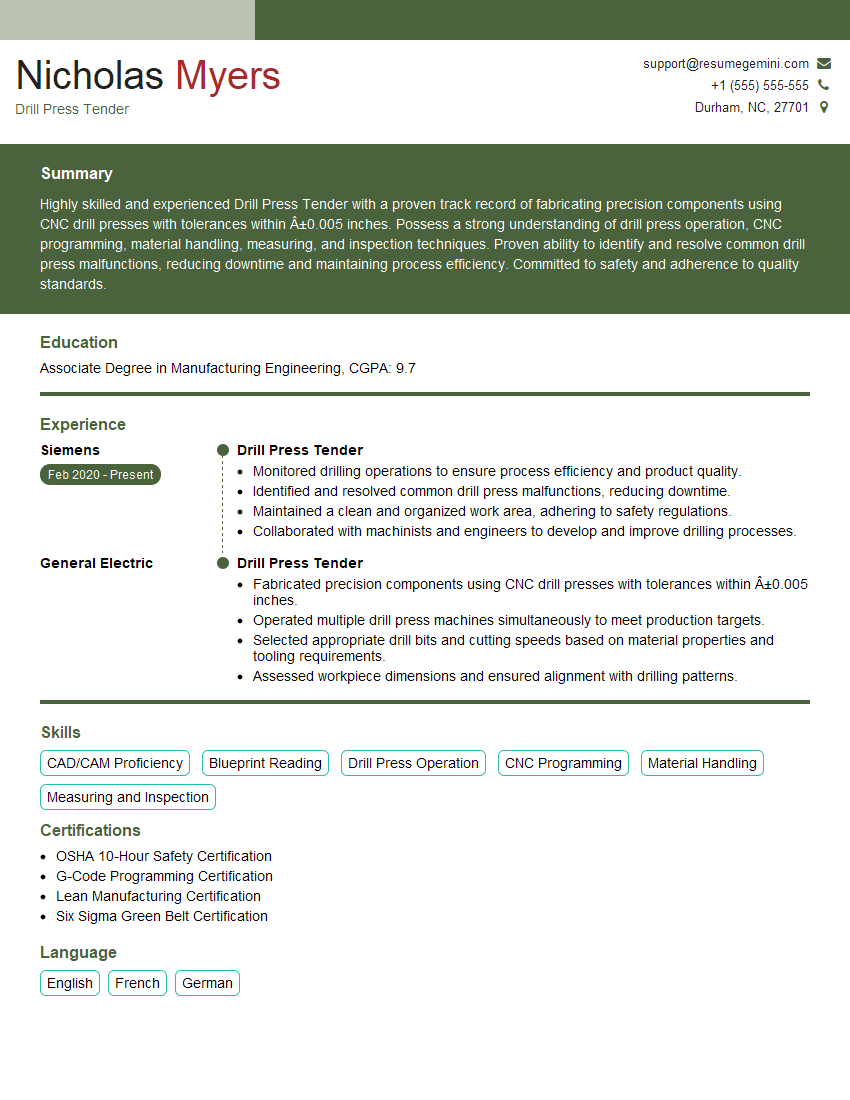

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drill Press Tender

1. What are the different types of drill presses and their uses?

There are various types of drill presses, each designed for specific applications. The most common types include:

- Benchtop drill press: Compact and ideal for small-scale drilling operations in workshops or garages.

- Floor drill press: Larger and more powerful, suitable for heavy-duty drilling tasks in industrial settings.

- Radial arm drill press: Allows for precise drilling over a large area, making it suitable for large workpieces or irregular angles.

- Magnetic drill press: Portable and used for drilling on metal surfaces, especially in construction or shipbuilding.

- Turret drill press: Features multiple spindles, enabling simultaneous drilling of multiple holes in a workpiece.

2. What are the key parameters to consider when selecting the right drill bit for a specific task?

Factors to consider:

- Material of the workpiece: Different materials require specific drill bit materials, such as high-speed steel (HSS) for metals or carbide tips for harder materials.

- Diameter and depth of the hole: The bit’s diameter should match the desired hole size, and its length should be appropriate for the hole depth.

- Hole quality requirements: Precision drill bits provide cleaner holes with less burring, while standard bits are suitable for general-purpose drilling.

- Type of drilling operation: Different drilling methods, such as hand drilling or CNC machining, may require specialized drill bits.

- Compatibility with the drill press: The bit’s shank must be compatible with the chuck or adapter on the drill press.

Other factors:

- Bit geometry: The cutting edges, rake angle, and flute design influence the drilling efficiency and hole quality.

- Coolants and lubricants: Some drilling operations require coolants or lubricants to reduce friction and improve bit life.

3. How does the spindle speed and feed rate affect the drilling process?

- Spindle speed: Higher speeds increase the cutting action, resulting in faster drilling rates. However, excessive speed can generate excessive heat and premature bit wear.

- Feed rate: The rate at which the drill bit advances into the workpiece. A proper feed rate ensures efficient chip removal and prevents the bit from overloading or breaking.

- Relationship between speed and feed: A balanced combination of speed and feed is crucial. Higher speeds require lower feed rates to prevent overheating, while lower speeds can benefit from increased feed rates for faster drilling.

4. What are the common sources of error in drilling operations and how can they be prevented or minimized?

- Runout: Misalignment between the drill bit and the spindle, resulting in uneven holes and tool wear. Can be minimized by using precision collets or adapters.

- Drill bit wobble: Excessive vibration or deflection of the drill bit, leading to inaccurate holes. Can be prevented by using sharp bits, proper bit selection, and ensuring the workpiece is securely clamped.

- Overheating: Excessive friction between the bit and workpiece, causing heat buildup and premature bit wear. Can be minimized by using coolants or lubricants, reducing spindle speed, or using a drill bit with a proper rake angle.

- Burring: Formation of raised edges around the drilled hole. Can be reduced by using sharp drill bits, controlling feed rate, and using a deburring tool after drilling.

5. Describe the safety precautions that should be followed when operating a drill press.

- Wear appropriate safety gear: Eye protection, gloves, and hearing protection are essential.

- Secure the workpiece: Ensure the workpiece is securely clamped to prevent movement during drilling.

- Inspect the drill bit: Check for any damage or wear before using it.

- Clear the work area: Remove any loose materials or debris to avoid tripping or entanglement.

- Follow proper drilling techniques: Use the correct spindle speed and feed rate, and apply appropriate force to the workpiece.

- Be aware of the surrounding area: Pay attention to the position of the drill bit and avoid contact with moving parts.

6. What are the maintenance procedures required for a drill press to ensure optimal performance and longevity?

- Regular cleaning: Remove dust, chips, and debris from the drill press regularly.

- Lubrication: Apply lubricant to moving parts, such as the spindle and chuck, as recommended by the manufacturer.

- Inspecting drill bits: Check for wear or damage and replace as needed.

- Spindle alignment: Ensure the spindle is properly aligned to prevent runout and wobble.

- Chuck maintenance: Clean and lubricate the chuck regularly to ensure proper bit retention and accuracy.

- Electrical safety: Check for loose connections or damaged wires and have them repaired by a qualified electrician.

7. What are the key differences between carbide and high-speed steel (HSS) drill bits?

- Material composition: Carbide bits are made of extremely hard tungsten carbide, while HSS bits are made of hardened alloy steel.

- Durability: Carbide bits have a longer lifespan and can withstand higher temperatures compared to HSS bits.

- Cutting efficiency: Carbide bits cut faster and produce cleaner holes due to their superior hardness.

- Versatility: HSS bits are more versatile and can be used on a wider range of materials than carbide bits.

- Cost: Carbide bits are typically more expensive than HSS bits.

8. Describe the process of drilling a hole using a drill press.

The process of drilling a hole using a drill press involves several steps:

- Preparation: Select the appropriate drill bit and ensure the workpiece is securely clamped.

- Setting up the drill press: Adjust the spindle speed and feed rate based on the material and bit size.

- Drilling: Slowly lower the drill bit into the workpiece, maintaining a steady feed rate.

- Cooling and lubrication: If necessary, apply coolant or lubricant to reduce friction and extend bit life.

- Reaming or deburring: After drilling, a reamer or deburring tool can be used to improve hole quality and remove any burrs.

9. What is the purpose of a pilot hole and when is it necessary?

- Purpose: A pilot hole is a small hole drilled before the main hole to guide the larger drill bit.

- Necessity: Pilot holes are particularly useful when drilling into hard or thick materials to prevent the drill bit from wandering or breaking.

- Benefits: Using a pilot hole improves accuracy, reduces drill bit deflection, and extends bit life.

10. Describe the different types of drill press attachments and their uses.

- Drill chucks: Hold and rotate the drill bit.

- Arbors: Connect the drill bit to the spindle when the chuck is not suitable.

- Taper attachments: Allow for the use of tapered shank drill bits.

- Angle attachments: Enable drilling at angles other than 90 degrees.

- Compound tables: Provide precise positioning and adjustment of the workpiece.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drill Press Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drill Press Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drill Press Tenders are responsible for operating and maintaining drill presses, which are machines used to create precise holes in various materials.

1. Machine Operation

– Setup and operate drill presses to drill holes in accordance with specifications.

– Measure and mark materials for drilling.

– Select and install appropriate drill bits and cutting tools.

2. Machine Maintenance

– Perform routine maintenance and inspections on drill presses, including lubrication, cleaning, and adjustments.

– Identify and report any malfunctions or defects to maintenance personnel.

3. Quality Control

– Check hole dimensions and quality using measuring tools.

– Inspect parts for defects.

– Implement procedures to ensure adherence to quality standards.

4. Material Handling

– Load and unload materials from drill presses.

– Transport materials to and from designated areas.

– Maintain a clean and organized work area.

Interview Tips

Preparing for a Drill Press Tender interview requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

– Learn about the company’s industry, products, and operations.

– Understand the specific requirements and expectations for the Drill Press Tender position.

2. Highlight Your Technical Skills

– Emphasize your experience and proficiency in operating and maintaining drill presses.

– Describe your understanding of drill bit selection, cutting tools, and quality control procedures.

3. Demonstrate Attention to Detail

– Express your ability to follow instructions and specifications accurately.

– Explain how you ensure the accuracy and quality of drilled holes.

4. Show Safety Awareness

– Discuss your understanding of safety protocols for drill press operation.

– Mention your experience in using personal protective equipment and adhering to safety guidelines.

5. Practice Answering Common Interview Questions

– Prepare responses to questions about your experience, skills, and why you are interested in the position.

– Use the STAR method (Situation, Task, Action, Result) to provide clear and concise examples.

6. Ask Thoughtful Questions

– Prepare insightful questions that show your interest in the company and the position.

– Ask about the company’s production processes, quality standards, or opportunities for professional development.

7. Dress Professionally and Be Punctual

– First impressions matter. Dress appropriately for the interview and arrive on time.

– Punctuality and a professional demeanor demonstrate respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drill Press Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.