Are you gearing up for an interview for a Drill Setup Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Drill Setup Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

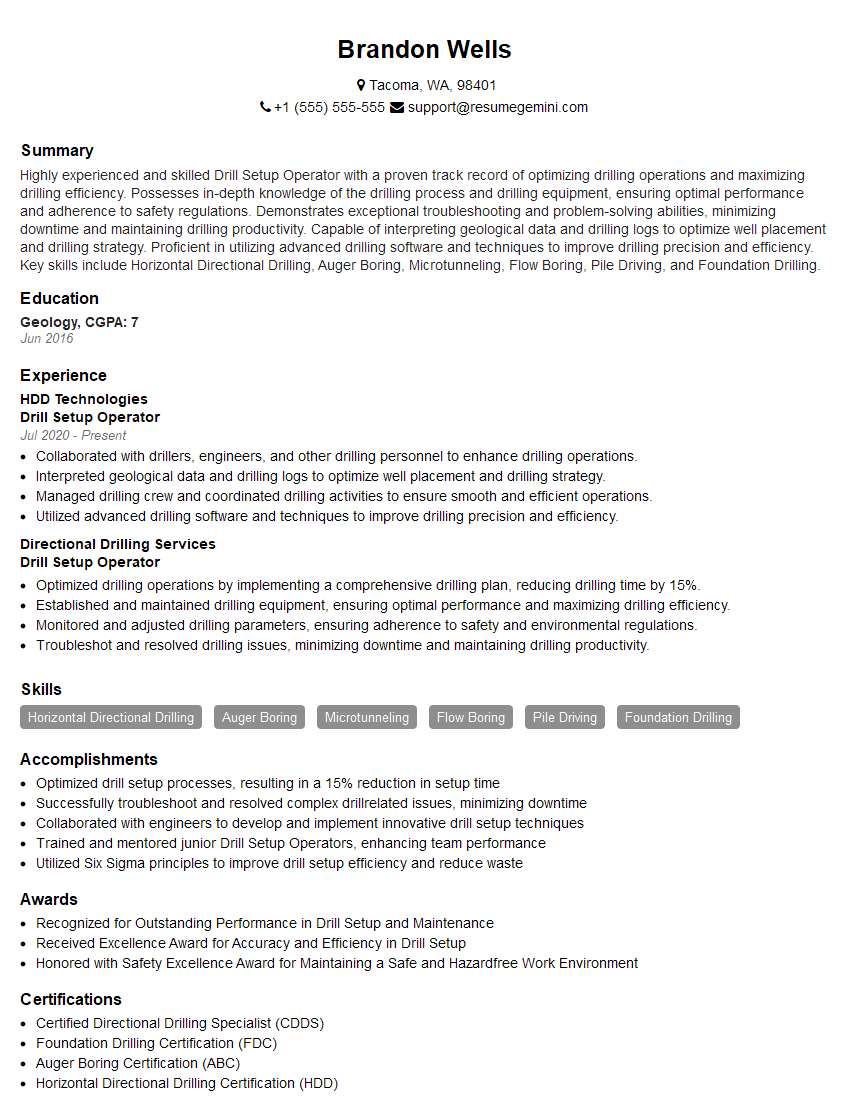

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drill Setup Operator

1. What are the key responsibilities of a Drill Setup Operator?

As a Drill Setup Operator, my primary responsibilities include:

- Setting up and operating drilling machines to create precise holes and patterns in various materials.

- Selecting and installing the appropriate drill bits and tools for each job.

- Adjusting machine settings, such as speed, feed, and depth, to optimize efficiency and accuracy.

- Monitoring and maintaining drilling equipment to ensure smooth and reliable operation.

- Inspecting workpieces for quality assurance and accuracy, identifying and correcting any defects.

2. Describe the different types of drill bits and their applications.

Twist Drills:

- General-purpose bits for drilling holes in various materials, including metal, plastic, and wood.

- Available in different sizes and lengths, with variations in flute and point designs.

Brad Point Drills:

- Designed for clean and precise holes, especially in thin or soft materials like wood.

- Feature a brad point that creates a small pilot hole, ensuring accuracy.

Forstner Bits:

- Used for creating flat-bottomed holes, commonly for hinge installation or cabinetry.

- Require a drill press for precise operation.

3. How do you ensure the accuracy and precision of drilled holes?

To ensure accuracy and precision, I follow these practices:

- Selecting the appropriate drill bit for the material and hole size.

- Using sharp and undamaged drill bits to minimize deviations.

- Securing the workpiece properly to prevent movement during drilling.

- Measuring and marking the drilling location accurately.

- Using a drill press or jig to guide the drill for greater precision.

4. How do you handle and maintain drilling equipment?

Proper handling and maintenance of drilling equipment is crucial for safety and performance. My approach includes:

- Wearing appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspecting equipment before and after use for any damage or defects.

- Lubricating moving parts regularly to ensure smooth operation.

- Cleaning and storing equipment properly after use to prevent corrosion and extend its lifespan.

5. Describe how you troubleshoot common problems encountered during drilling operations.

When troubleshooting, I follow a systematic approach:

- Identifying the problem and its symptoms accurately.

- Checking for loose connections, damaged parts, or dull drill bits.

- Adjusting machine settings, such as speed or feed, to optimize performance.

- Consulting technical manuals or seeking guidance from experienced colleagues.

6. How do you measure and ensure the quality of drilled holes?

I ensure the quality of drilled holes using various techniques:

- Inspecting holes visually for accuracy, cleanliness, and absence of defects.

- Using measuring tools, such as calipers or micrometers, to verify dimensions and tolerances.

- Conducting destructive or non-destructive tests to assess hole strength and integrity.

7. Describe the safety protocols you follow when operating drilling equipment.

Safety is paramount when operating drilling equipment. I strictly adhere to these protocols:

- Wearing appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Ensuring proper ventilation to minimize exposure to dust and fumes.

- Securely clamping the workpiece to prevent movement during drilling.

- Keeping the work area clean and free from tripping hazards.

8. How do you maximize productivity and efficiency in drilling operations?

To enhance productivity and efficiency, I implement these strategies:

- Optimizing machine settings, such as speed and feed, based on the material and drill bit used.

- Using automated or semi-automated equipment to reduce manual labor.

- Implementing preventive maintenance schedules to minimize downtime.

- Regularly reviewing and improving drilling techniques to enhance performance.

9. Describe your experience with different types of drilling machines.

Throughout my career, I have gained experience with various drilling machines, including:

- Radial arm drills for large-scale drilling operations.

- Magnetic drills for drilling on metal surfaces.

- CNC drilling machines for high-precision and automated drilling.

- Portable drills for drilling in various locations and orientations.

10. How do you stay updated with the latest advancements in drilling technology?

To stay current with advancements, I proactively pursue these strategies:

- Attending industry conferences and webinars.

- Reading technical journals and articles.

- Consulting with manufacturers and suppliers for information on new products and technologies.

- Participating in training and certification programs to enhance my skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drill Setup Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drill Setup Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Drill Setup Operator ensures the safe and efficient setup of drilling equipment for various drilling operations. The primary responsibilities of this role include:

1. Equipment Setup and Maintenance

- Assembling, installing, and maintaining drilling machinery and equipment, including drill rigs, pumps, and auxiliary systems.

- Inspecting and testing equipment to ensure proper functioning, and troubleshooting and resolving any issues.

- Calibrating and adjusting equipment for optimal performance and accuracy.

2. Drilling Plan Execution

- Following drilling plans and specifications to set up drill sites.

- Calculating and positioning drill bits and other drilling tools.

- Monitoring drilling progress and making necessary adjustments to ensure optimal drilling efficiency.

3. Safety and Compliance

- Adhering to all safety protocols and regulations during drilling operations.

- Ensuring that drilling equipment meets safety standards and is operated safely.

- Maintaining a clean and organized work area to minimize hazards.

4. Collaboration and Communication

- Collaborating with geologists, engineers, and other drilling personnel to determine drilling parameters.

- Communicating with supervisors, clients, and stakeholders to provide updates on drilling progress and resolve any issues.

- Documenting drilling activities and maintaining accurate records for future reference.

Interview Tips

To ace the interview for a Drill Setup Operator position, it’s crucial to prepare effectively. Here are some interview preparation tips and hacks:

1. Research the Company and Role

- Thoroughly research the company’s background, operations, and values to demonstrate your interest and knowledge.

- Familiarize yourself with the specific responsibilities and requirements of the Drill Setup Operator role.

2. Highlight Relevant Experience and Skills

- Emphasize your hands-on experience in operating and maintaining drilling equipment.

- Showcase your knowledge of drilling plans and safety protocols.

- Provide specific examples of your problem-solving abilities and attention to detail.

3. Demonstrate Technical Proficiency

- Be prepared to discuss your understanding of drilling equipment, including drill rigs, pumps, and related systems.

- Explain your knowledge of drilling techniques and best practices.

- Highlight your ability to use specialized equipment and software for drilling operations.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Some questions you may encounter include:

- Tell me about your experience with drilling equipment setup and operation.

- How do you ensure the safe and efficient execution of drilling plans?

- Describe a challenging drilling situation you faced and how you resolved it.

5. Practice and Seek Feedback

- Practice answering interview questions aloud or with a friend or family member.

- Seek feedback on your answers to improve your articulation and confidence.

- Rehearse answering technical questions and providing specific examples.

6. Maintain a Professional Demeanor

- Dress appropriately for the interview and arrive on time.

- Be polite, respectful, and articulate during the interview.

- Maintain eye contact, ask clarifying questions, and actively listen to the interviewer’s questions and instructions.

7. Follow Up

- After the interview, send a thank-you email to the interviewer, reiterating your interest in the position and highlighting key points from your interview.

- Follow up respectfully if you haven’t heard back within the expected timeframe.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Drill Setup Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Drill Setup Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.