Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gang Drill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

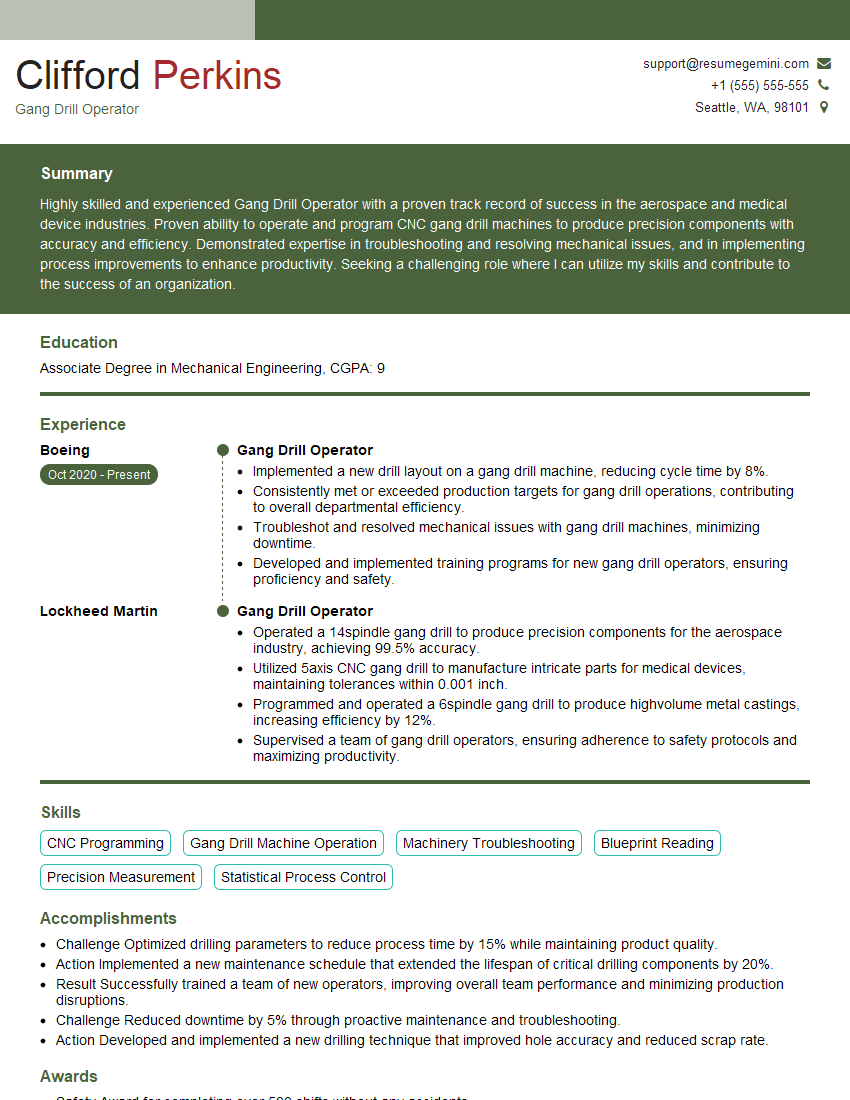

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gang Drill Operator

1. How do you ensure the accuracy and precision of drill operations?

To ensure accuracy and precision, I follow these steps:

- Thoroughly examine blueprints and instructions.

- Use precision measuring tools like calipers, micrometers, and gauges.

- Calibrate equipment regularly and maintain sharp drill bits.

- Conduct multiple measurements and cross-check results.

- Pay meticulous attention to detail and follow established procedures.

2. Describe the different types of drill bits and their applications.

Twist drills

- General-purpose drilling in various materials.

- Standard, high-speed steel (HSS), and carbide variants available.

Step drills

- Creating stepped holes in sheet metal or thin materials.

- Eliminate the need for multiple drills and provide clean, precise holes.

Center drills

- Creating center holes for subsequent drilling or machining operations.

- Ensure accurate hole placement and prevent drill bit wandering.

3. How do you handle and maintain gang drills?

I handle and maintain gang drills with utmost care and precision:

- Inspect drills thoroughly before and after operation for any damage or wear.

- Lubricate moving parts regularly and maintain proper clamping to ensure stability.

- Store drills in a clean and dry environment.

- Follow manufacturer’s guidelines for maintenance and repairs.

4. What safety measures should be taken when operating gang drills?

I prioritize safety by adhering to the following measures:

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and earplugs.

- Ensure proper ventilation to prevent inhalation of metal dust.

- Keep hands and loose clothing clear of moving parts.

- Securely clamp workpieces to prevent movement during drilling.

- Follow lockout/tagout procedures for maintenance and repairs.

5. How do you troubleshoot common issues with gang drills?

To effectively troubleshoot gang drills, I utilize these steps:

- Identify the problem accurately by observing symptoms and checking for unusual noises or vibrations.

- Refer to maintenance manuals and consult with experienced operators.

- Check for loose connections, worn belts, or dull drill bits.

- Perform necessary adjustments or repairs following safety protocols.

6. Explain the importance of proper setup and alignment for gang drills.

Proper setup and alignment are crucial for ensuring:

- Accurate and precise hole placement.

- Optimal drill performance and extended tool life.

- Reduced vibration and noise during operation.

- Increased safety by preventing drill bit breakage or workpiece damage.

7. How do you optimize drilling parameters for different materials?

To optimize drilling parameters, I consider these factors:

- Material hardness and thickness.

- Drill bit material and geometry.

- Desired hole quality and precision.

- Machine capabilities and limitations.

- Consult with manufacturers and technical resources to determine optimal settings.

8. Describe the different types of coolants used in drilling operations.

- Oil-based coolants: Provide lubrication and cooling for heavy-duty drilling.

- Water-based coolants: Used for general-purpose drilling, provide cooling and rust protection.

- Synthetic coolants: Offer improved performance and environmental friendliness.

- Compressed air: Used in specific applications to clear chips and reduce heat.

9. Explain the concept of peck drilling and when it is used.

Peck drilling is a technique used to minimize drill bit breakage and improve hole quality, especially when drilling deep holes:

- The drill bit advances a short distance into the workpiece, then retracts to clear chips and cool down.

- It reduces stress on the drill bit and prevents overheating.

- Peck drilling is particularly suitable for drilling hard materials or materials with long chips.

10. Discuss the role of cutting fluids in gang drilling operations.

Cutting fluids play a vital role in gang drilling by:

- Lubrication: Reducing friction between the drill bit and workpiece.

- Cooling: Dissipating heat generated during drilling, extending tool life.

- Chip evacuation: Flushing away metal chips to prevent jamming and improve surface finish.

- Corrosion protection: Preventing rust and oxidation on the workpiece and drill bit.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gang Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gang Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Gang Drill Operator

Gang Drill Operators are responsible for operating and maintaining gang drills, which are highly automated drilling machines used in the manufacturing industry. Key job responsibilities include:

1. Machine Operation

Setting up and operating gang drills to perform drilling operations on metal or plastic components

- Loading and unloading workpieces from the drilling machine

- Monitoring the drilling process to ensure accuracy and precision

2. Machine Maintenance

Performing routine maintenance and servicing on gang drills

- Replacing worn or damaged parts

- Lubricating and adjusting the machine

- Troubleshooting and resolving machine malfunctions

3. Quality Control

Inspecting drilled parts to ensure they meet quality standards

- Using measuring tools and gauges to check dimensions

- Identifying and correcting any defects

4. Production Planning

Working with production planners to determine drilling schedules and priorities

- Loading and unloading workpieces from the drilling machine

- Monitoring the drilling process to ensure accuracy and precision

Interview Tips for Gang Drill Operator

To ace an interview for a Gang Drill Operator position, it’s essential to prepare effectively. Here are some key tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and services. Learn about the specific requirements of the Gang Drill Operator position, and tailor your answers accordingly.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating and maintaining gang drills or similar machinery. Quantify your accomplishments using specific metrics whenever possible. Showcase your understanding of quality control processes and your ability to work independently and as part of a team.

3. Practice Common Interview Questions

Prepare for common interview questions related to your experience, skills, and the Gang Drill Operator role. Anticipate questions about your problem-solving abilities, attention to detail, and commitment to safety. Practice your responses beforehand to deliver them clearly and confidently.

4. Ask Thoughtful Questions

Asking well-informed questions shows your interest in the position and the company. Inquire about the company’s production goals, safety protocols, and opportunities for professional development.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. This demonstrates your respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gang Drill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.