Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Boring Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

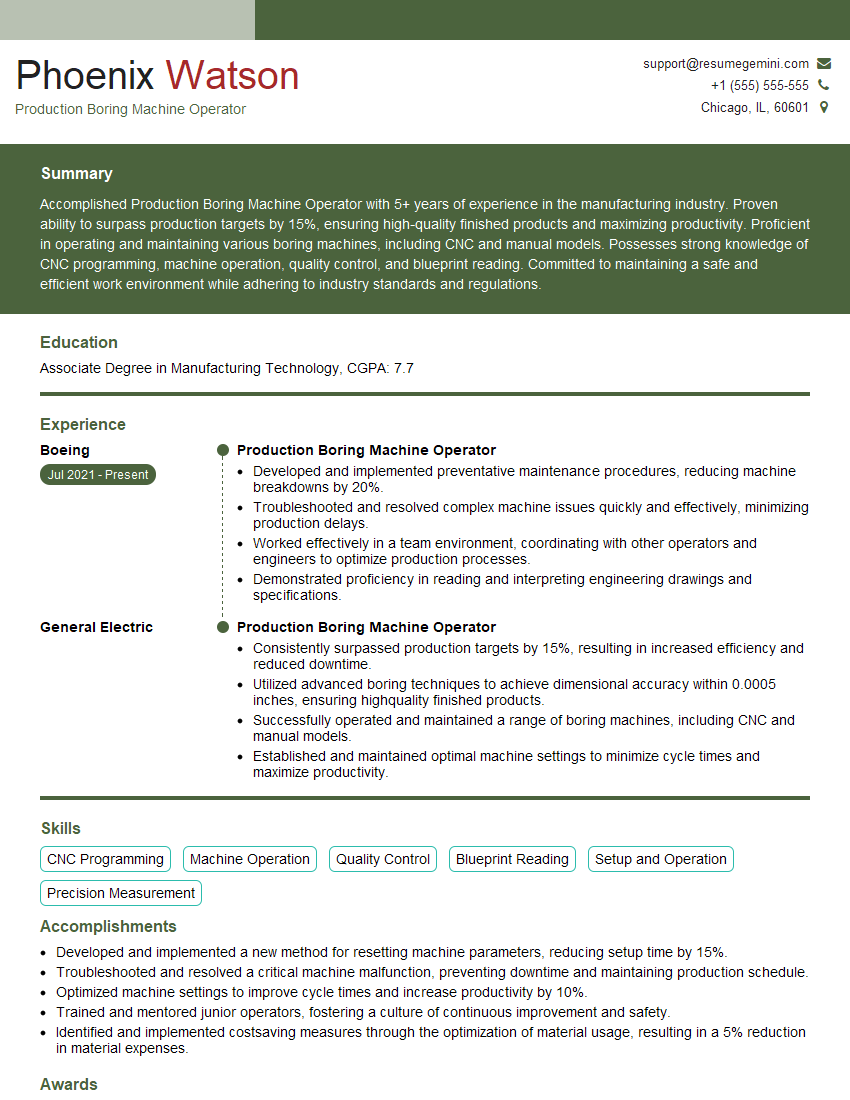

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Boring Machine Operator

1. What are the different types of boring machines and their applications?

- Horizontal Boring Machine: Used for boring large holes in heavy workpieces, such as engine blocks and machine frames.

- Vertical Boring Machine: Used for boring holes in workpieces that are too large to be handled on a horizontal machine.

- Jig Boring Machine: Used for precision boring of holes in jigs and fixtures.

- Line Boring Machine: Used for boring long, straight holes in workpieces, such as crankshafts and camshafts.

2. How do you set up and operate a boring machine?

subheading of the answer

- Mount the workpiece on the machine table.

- Select the appropriate tooling for the job.

- Set the spindle speed and feed rate.

- Start the machine and carefully guide the tool into the workpiece.

- Monitor the progress of the operation and make adjustments as necessary.

subheading of the answer

- It is important to follow the manufacturer’s instructions for the specific machine being used.

- Always wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

3. What are the different types of boring tools and their uses?

- Boring Bar: A long, slender tool with a cutting edge at the end. Used for boring holes in solid materials.

- Boring Head: A tool that holds a boring bar and can be adjusted to bore holes of different diameters.

- Boring Bit: A small, single-point cutting tool used for boring holes in thin materials.

- Counterbore: A tool used to enlarge the end of a hole to a larger diameter.

- Countersink: A tool used to create a conical seat for a screw or rivet head.

4. How do you troubleshoot common problems with boring machines?

- Chatter: Caused by excessive vibration. Can be resolved by adjusting the spindle speed or feed rate, or by using a more rigid workpiece setup.

- Tool breakage: Caused by using a dull or damaged tool, or by excessive cutting forces. Can be resolved by replacing the tool or by reducing the cutting forces.

- Poor surface finish: Caused by using a worn or damaged tool, or by excessive cutting forces. Can be resolved by replacing the tool or by reducing the cutting forces.

- Dimensional inaccuracy: Caused by using a worn or damaged tool, or by improper machine setup. Can be resolved by replacing the tool or by adjusting the machine setup.

5. What are the safety precautions that must be taken when operating a boring machine?

- Always wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Inspect the machine and tooling before each use.

- Securely mount the workpiece before starting the machine.

- Never reach into the machine while it is running.

- Stop the machine and disconnect the power before making any adjustments.

- Follow the manufacturer’s instructions for the specific machine being used.

6. How do you maintain a boring machine?

- Clean the machine regularly.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine and tooling regularly for wear and damage.

- Calibrate the machine regularly.

- Follow the manufacturer’s instructions for the specific machine being used.

7. What are the quality control procedures that must be followed when operating a boring machine?

- Inspect the workpiece before and after boring.

- Measure the workpiece to ensure that it meets the required dimensions.

- Check the surface finish of the workpiece.

- Keep records of all quality control checks.

- Follow the manufacturer’s instructions for the specific machine being used.

8. What are the different types of materials that can be bored?

- Metals: Ferrous metals (such as steel and cast iron) and non-ferrous metals (such as aluminum and copper).

- Plastics: Thermoplastics (such as ABS and PVC) and thermosets (such as epoxy and phenolic).

- Wood

- Composites

9. What are the different types of coolant that can be used in boring operations?

- Water-based coolants

- Oil-based coolants

- Synthetic coolants

- The type of coolant used will depend on the material being bored and the specific boring operation being performed.

10. What are the advantages of using a boring machine over other machining methods?

- Boring machines can produce holes with very high precision and accuracy.

- Boring machines can produce holes of various sizes and shapes.

- Boring machines can be used to bore holes in a variety of materials.

- Boring machines are relatively easy to operate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Boring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Boring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Boring Machine Operators are responsible for operating boring machines to create precise holes in metal or plastic components. They work in a variety of industries, including automotive, aerospace, and manufacturing.

1. Operate and maintain boring machines

This involves setting up the machine, loading and unloading parts, and monitoring the process. Operators must also perform regular maintenance on the machine to ensure that it is running smoothly and efficiently.

- Follow written instructions and blueprints to ensure proper operation of the boring machine.

- Inspect and maintain the machine, performing routine checks and making necessary adjustments.

2. Inspect parts for quality

Operators must be able to inspect parts to ensure that they meet the required specifications. They must also be able to identify any defects in the parts and take corrective action.

- Measure and inspect parts using precision measuring instruments to ensure they meet specifications.

- Identify and report any defects or irregularities in the parts to ensure product quality.

3. Work with other team members

Operators must be able to work with other team members to ensure that the production process runs smoothly. They must also be able to communicate effectively with supervisors and engineers.

- Collaborate with other team members to ensure the smooth flow of work and meet production targets.

- Communicate effectively with supervisors and engineers to provide updates and address any technical issues.

4. Follow safety procedures

Operators must be familiar with and follow all safety procedures. They must also be able to identify and avoid potential hazards in the workplace.

- Adhere to established safety protocols to minimize risk and ensure a safe working environment.

- Identify and report any potential hazards or unsafe conditions to ensure a safe work environment.

Interview Tips

Preparing thoroughly for your interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Production Boring Machine Operator position:

1. Research the company and the position

Take the time to learn about the company’s history, products, and services. You should also research the specific position you are applying for and its responsibilities. This will help you answer questions intelligently and demonstrate your interest in the position.

- Visit the company’s website and social media pages to learn about their culture and values.

- Read online reviews and articles about the company to get insights into its reputation and work environment.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare a brief and engaging introduction that highlights your relevant skills and experience.

- Think about specific examples from your work history that demonstrate your abilities and accomplishments.

3. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview. You should also arrive on time to show that you are respectful of the interviewer’s time.

- Choose attire that is clean, pressed, and appropriate for an office setting.

- Plan your route in advance and allow extra time for traffic or unexpected delays.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about their work and positive about their abilities. Be sure to convey your passion for the position and your confidence in your ability to succeed.

- Maintain a positive and upbeat attitude throughout the interview.

- Highlight your strengths and accomplishments while remaining humble and respectful.

Next Step:

Now that you’re armed with the knowledge of Production Boring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Production Boring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini