Feeling lost in a sea of interview questions? Landed that dream interview for Printed Circuit Boards Pinner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printed Circuit Boards Pinner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

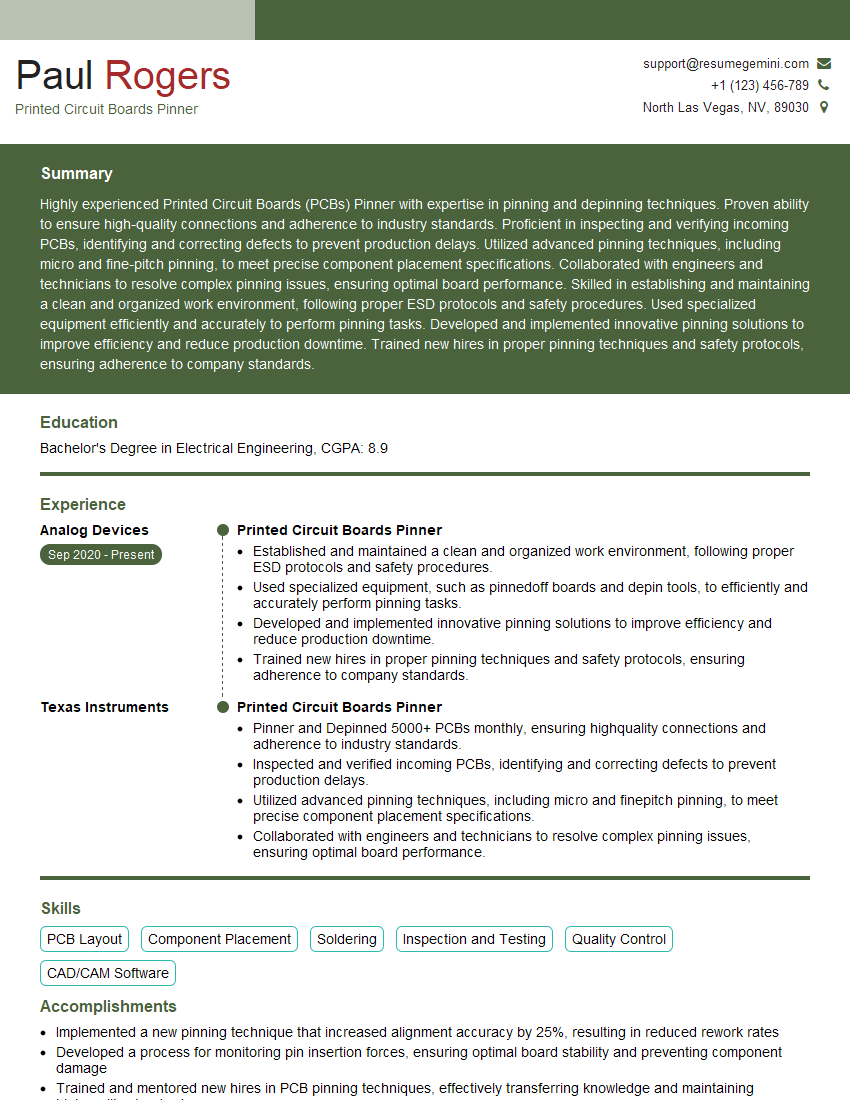

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Pinner

1. Explain the different types of Printed Circuit Boards (PCBs) and their applications?

Different types of PCBs include:

- Single-layer PCBs: These have a single layer of copper traces on one side of the board.

- Double-layer PCBs: These have copper traces on both sides of the board, connected by vias.

- Multilayer PCBs: These have multiple layers of copper traces, separated by insulating layers.

Applications of PCBs include:

- Consumer electronics (e.g., smartphones, laptops)

- Industrial equipment (e.g., PLCs, robots)

- Medical devices (e.g., pacemakers, imaging systems)

- Automotive systems (e.g., engine control modules, navigation systems)

2. What are the key factors to consider when designing a PCB?

Key factors to consider when designing a PCB include:

- Electrical requirements (e.g., voltage, current, impedance)

- Mechanical requirements (e.g., size, shape, mounting method)

- Environmental requirements (e.g., temperature range, humidity)

- Manufacturing considerations (e.g., materials, processes, cost)

- Reliability requirements (e.g., lifespan, failure rate)

3. Describe the process of manufacturing a PCB?

The process of manufacturing a PCB typically involves the following steps:

- Designing the PCB layout

- Creating a photomask

- Applying a solder mask

- Printing the copper traces

- Etching the copper

- Applying a protective coating

- Assembling the components

4. What are the different types of soldering techniques used in PCB assembly?

Different types of soldering techniques used in PCB assembly include:

- Hand soldering: This involves using a soldering iron and solder to manually solder components to the PCB.

- Wave soldering: This involves passing the PCB over a wave of molten solder to solder the components.

- Reflow soldering: This involves heating the PCB in an oven to melt the solder paste and solder the components.

5. What are the common quality control procedures used in PCB manufacturing?

Common quality control procedures used in PCB manufacturing include:

- Visual inspection

- Electrical testing

- Environmental testing

- Statistical process control

6. What are the challenges involved in designing a high-speed PCB?

Challenges involved in designing a high-speed PCB include:

- Minimizing signal loss and crosstalk

- Ensuring impedance matching

- Controlling noise

- Managing heat dissipation

7. What are the advantages of using flexible PCBs?

Flexibility

- Can be bent and folded without damage

- Suitable for applications with space constraints

Reliability

- Resistant to vibration and shock

- High-temperature tolerance

Cost-effectiveness

- Can reduce assembly time and costs

- Eliminate the need for connectors

8. How do you ensure the quality of PCBs produced by your company?

We ensure the quality of our PCBs through the following measures:

- Using high-quality materials

- Implementing strict manufacturing processes

- Conducting thorough testing

- Maintaining ISO certification

- Continuously improving our processes and procedures

9. What are the latest trends in PCB manufacturing?

Latest trends in PCB manufacturing include:

- Miniaturization

- Increased use of flexible PCBs

- Adoption of advanced manufacturing technologies (e.g., laser cutting, 3D printing)

- Focus on sustainability

10. What are your strengths and weaknesses when it comes to PCB design and manufacturing?

My strengths are:

- Strong understanding of PCB design and manufacturing principles

- Experience with a variety of PCB design software

- Excellent attention to detail

- Ability to work independently and as part of a team

My weaknesses are:

- Limited experience with high-speed PCB design

- Still learning about the latest trends in PCB manufacturing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Pinner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Pinner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Printed Circuit Boards Pinner

A Printed Circuit Boards (PCB) Pinner is responsible for assembling and testing printed circuit boards (PCBs) in accordance with engineering specifications. Key job responsibilities include:

1. Assembly

Assemble PCBs using various hand tools, equipment, and materials as per blueprints and schematics.

2. Inspection and Testing

Inspect and test PCBs for defects, ensuring they meet quality standards and specifications.

3. Troubleshooting

Troubleshoot and repair faulty PCBs, identifying and resolving defects and ensuring proper functionality.

4. Process Optimization

Analyze and improve assembly processes to enhance efficiency and reduce production time.

5. Safety and Quality Control

Adhere to safety protocols and quality control measures to maintain a safe and high-quality work environment.

Interview Preparation Tips for a Printed Circuit Boards Pinner

To prepare effectively for a Printed Circuit Boards Pinner interview, follow these tips:

1. Research the Company and Position

Get familiar with the company’s mission, values, and products, as well as the specific responsibilities of the Pinner role.

2. Practice Technical Skills

Review basic electrical principles and familiarize yourself with common PCB assembly techniques.

3. Highlight Relevant Experience

Emphasize your experience in assembling, inspecting, or troubleshooting PCBs in previous roles.

4. Prepare for Common Interview Questions

Research typical interview questions for PCB Pinners, such as “Describe your experience in soldering and troubleshooting PCBs.” and “How do you ensure the accuracy and quality of your work?”

5. Showcase Problem-Solving Abilities

Provide examples of how you have solved problems and ensured the efficiency of PCB assembly processes.

6. Be Enthusiastic and Professional

Demonstrate passion for the field and a positive attitude during the interview.

Next Step:

Now that you’re armed with the knowledge of Printed Circuit Boards Pinner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Printed Circuit Boards Pinner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini