Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Radial Drill Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

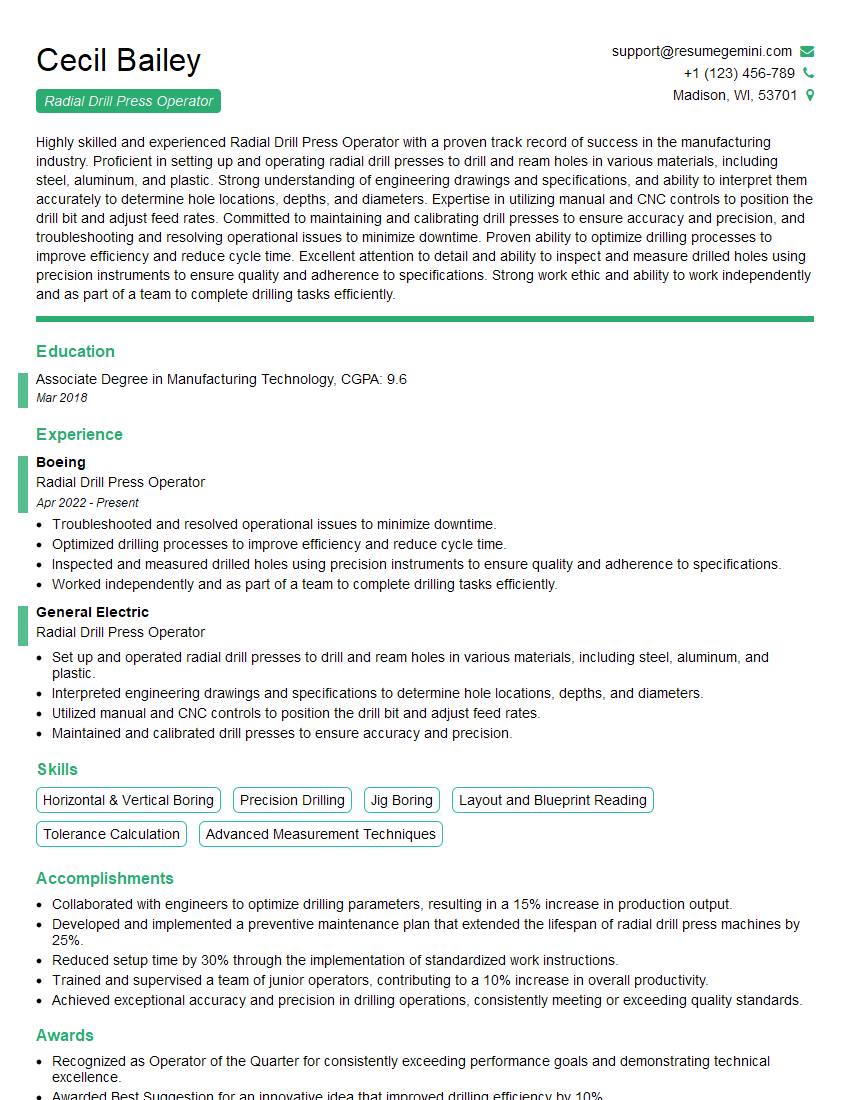

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radial Drill Press Operator

1. What is the main function of a radial drill press operator?

The main function of a radial drill press operator is to operate a radial drill press to drill, bore, and ream holes in metal and other materials. They also set up and adjust the machine, select and install the appropriate tooling, and inspect the finished work.

2. What are the different types of radial drill presses?

Column-mounted

- The most common type of radial drill press, with the drill head mounted on a vertical column.

- Offers a wide range of motion and can handle large workpieces.

Base-mounted

- The drill head is mounted on a base plate.

- Usually smaller and less powerful than column-mounted models.

Portable

- Lightweight and easy to move around.

- Typically used for smaller jobs.

3. What are the key safety precautions when operating a radial drill press?

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Secure the workpiece properly before starting the machine.

- Never operate the machine with worn or damaged parts.

- Keep the work area clean and free of debris.

- Follow all manufacturer’s instructions and safety guidelines.

4. How do you set up a radial drill press for a specific job?

- Select the appropriate drill bit and insert it into the drill chuck.

- Adjust the spindle speed and feed rate according to the material and hole size.

- Position the workpiece on the table and secure it with clamps.

- Set the depth stop to the desired hole depth.

- Start the machine and carefully lower the drill bit into the workpiece.

5. How do you inspect the finished work?

- Check the hole size and depth with a micrometer or other measuring tool.

- Inspect the hole surface for any defects.

- Ensure that the workpiece is free of burrs or other hazards.

6. What are some common troubleshooting tips for radial drill presses?

- If the drill bit is not cutting properly, check the sharpness of the bit and the spindle speed.

- If the workpiece is not securely clamped, the hole may not be accurate.

- If the machine is making excessive noise or vibration, it may be necessary to lubricate or adjust the machine.

7. What are the different types of cutting tools that can be used on a radial drill press?

- Twist drills

- Boring bars

- Reamers

- Taps

- Countersinks

8. What are the advantages of using a radial drill press over other types of drilling machines?

- Radial drill presses offer a wide range of motion, making them suitable for drilling holes in large workpieces.

- They are also relatively easy to set up and operate.

- Radial drill presses are durable and can withstand heavy use.

9. What are the disadvantages of using a radial drill press?

- Radial drill presses can be large and expensive.

- They can also be difficult to move around.

- Radial drill presses require a skilled operator to use safely and efficiently.

10. What are the career opportunities for radial drill press operators?

- Radial drill press operators can find work in a variety of industries, including manufacturing, construction, and automotive.

- With experience, they can advance to supervisory or management positions.

- Radial drill press operators can also specialize in a particular area, such as jig boring or deep hole drilling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radial Drill Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radial Drill Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A radial drill press operator is responsible for operating a radial drill press to create holes in metal, wood, or plastic. They must be able to read and interpret blueprints and drawings, and have a good understanding of the different types of drill bits and how to use them. They must also be able to maintain the drill press and keep it in good working order.

1. Set up and operate the radial drill press

This involves mounting the workpiece on the table, selecting the appropriate drill bit and speed, and aligning the drill bit with the desired location.

- Mount the workpiece on the table using clamps or a vise.

- Select the appropriate drill bit for the material and size of the hole.

- Set the drill speed and feed rate.

- Align the drill bit with the desired location using the crosshairs or laser pointer.

2. Drill holes in the workpiece

This involves starting the drill press, feeding the drill bit into the workpiece, and monitoring the progress of the hole.

- Start the drill press and slowly feed the drill bit into the workpiece.

- Monitor the progress of the hole and adjust the feed rate as necessary.

- Stop the drill press when the hole is complete.

3. Measure and inspect the holes

This involves using a micrometer or other measuring tool to ensure that the holes are the correct size and depth.

- Measure the diameter of the hole using a micrometer.

- Measure the depth of the hole using a depth gauge.

- Inspect the hole for any defects, such as burrs or chips.

4. Maintain the radial drill press

This involves cleaning, lubricating, and adjusting the drill press as needed.

- Clean the drill press table and spindle.

- Lubricate the drill press bearings and gears.

- Adjust the drill press speed and feed rate as necessary.

- Troubleshoot any problems with the drill press.

Interview Tips

To ace the interview for a radial drill press operator job, it is important to be prepared to answer questions about your experience, skills, and knowledge. You should also be familiar with the different types of radial drill presses and their applications. Here are some tips to help you prepare for the interview:

1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the job. You can research the company’s website, LinkedIn page, and Glassdoor reviews.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully and make a list of the key skills and experience that the employer is looking for.

- Read Glassdoor reviews to get an idea of the company’s culture and the work environment.

2. Prepare answers to common interview questions

There are some common interview questions that are likely to be asked in an interview for a radial drill press operator job. These questions may include:

- Tell me about your experience operating a radial drill press.

- What are the different types of radial drill presses and their applications?

- How do you maintain a radial drill press?

- What are some of the safety precautions that must be taken when operating a radial drill press?

- Do you have any questions for me?

3. Practice your answers

Once you have prepared answers to common interview questions, it is important to practice your answers. This will help you to feel more confident and articulate during the interview.

- Practice answering the questions out loud to yourself or to a friend or family member.

- Record yourself answering the questions and then watch the playback to identify areas where you can improve.

- Time yourself to make sure that you can answer the questions within the allotted time.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose shoes that are comfortable and appropriate for the workplace.

5. Be on time

Punctuality is important for any job interview, but it is especially important for a job that requires precision and attention to detail, such as a radial drill press operator job. Make sure to arrive for your interview on time, or even a few minutes early.

- Plan your route to the interview in advance.

- Allow extra time for traffic or unexpected delays.

- If you are running late, call the interviewer to let them know.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Radial Drill Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.