Are you gearing up for a career in Abrasive Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Abrasive Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

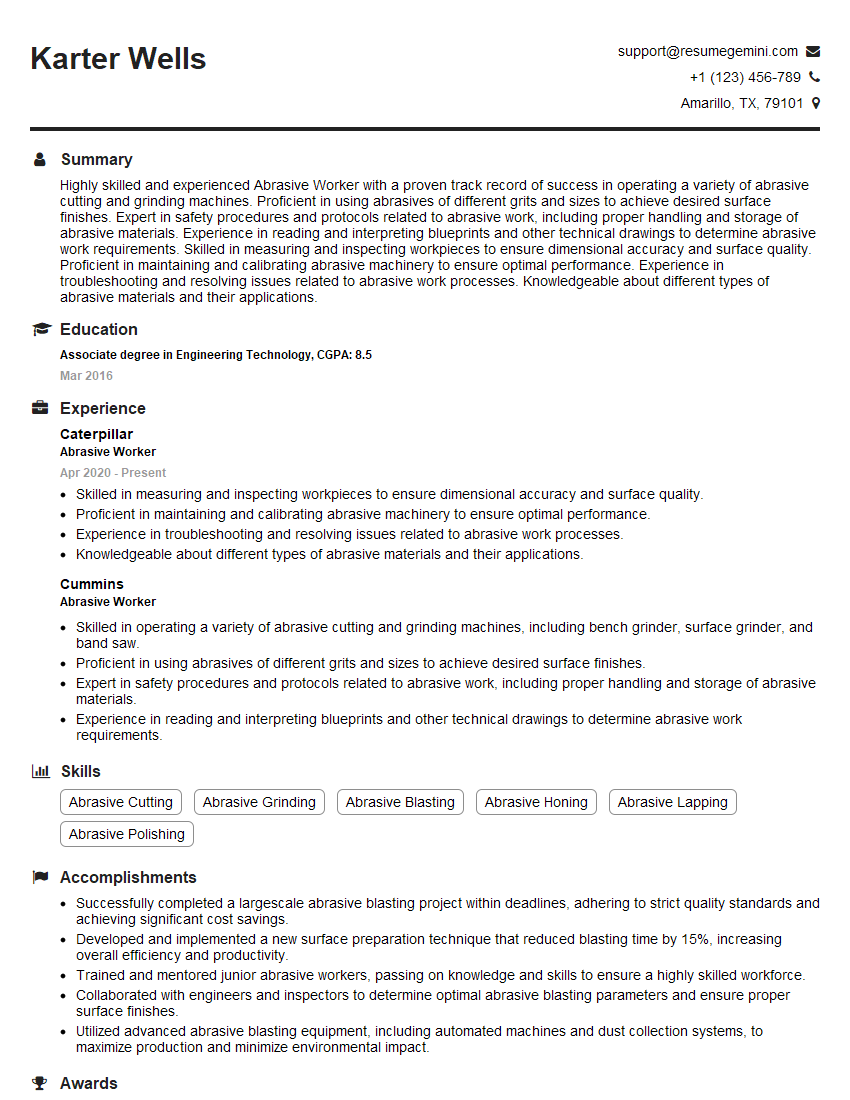

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Abrasive Worker

1. Which safety precautions should be taken when working with abrasives?

Answer:

- Wear proper protective gear, including safety glasses, gloves, and a respirator.

- Ensure proper ventilation to remove dust and fumes.

- Inspect equipment regularly for defects or damage.

- Follow manufacturers’ instructions for safe use and storage.

- Handle abrasives carefully to avoid injury or damage.

2. Describe the different types of abrasives and their applications.

Natural abrasives

- Sandstone: Used for cutting, grinding, and polishing.

- Emery: Used for grinding, lapping, and polishing.

Artificial abrasives

- Aluminum oxide: Used in grinding wheels, coated abrasives, and lapping compounds.

- Silicon carbide: Used in cutting wheels, grinding wheels, and coated abrasives.

3. What is the difference between bonded and coated abrasives?

Answer:

- Bonded abrasives are made by bonding abrasive particles to a wheel or other backing using a bonding agent.

- Coated abrasives are made by adhering abrasive particles to a backing using an adhesive.

4. What is the purpose of grinding fluid when using abrasives?

Answer:

- Lubricates the workpiece and cutting tool, reducing friction and heat.

- Cools the workpiece and cutting tool, preventing overheating.

- Flushes away debris and chips, keeping the workpiece and cutting tool clean.

- Protects the workpiece from oxidation and corrosion.

5. What are the different methods for sharpening abrasive tools?

Answer:

- Grinding wheels

- Diamond dressing tools

- CBN dressing tools

6. How do you determine the correct grit size for a particular abrasive application?

Answer:

- Consider the hardness and material of the workpiece.

- Determine the desired surface finish.

- Consult manufacturers’ recommendations for specific applications.

7. What are the common causes of abrasive wheel failure?

Answer:

- Excessive speed

- Incorrect mounting

- Impact or vibration

- Overloading

8. How do you maintain abrasive wheels to ensure safety and effectiveness?

Answer:

- Inspect wheels regularly for cracks or damage.

- Dress wheels as needed to remove glazing and restore sharpness.

- Store wheels properly to prevent damage.

9. What are the advantages of using diamond abrasives over other types?

Answer:

- Extreme hardness and durability

- High cutting efficiency

- Excellent surface finishes

10. Describe the process of lapping and its applications.

Answer:

- A fine abrasive process used to achieve extremely precise dimensions and surface finishes.

- Applications include precision optics, gauges, and semiconductor devices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Abrasive Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Abrasive Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Abrasive workers are responsible for operating and maintaining abrasive equipment, which is used to grind, smooth, or polish materials. They may work in a variety of industries, including manufacturing, construction, and automotive repair.

Their key responsibilities include:

1. Handling and operating abrasive equipment

Abrasive workers must be able to safely and efficiently operate abrasive equipment, which can include grinders, sanders, and polishers. They must be familiar with the different types of equipment and how to use them properly.

2. Selecting and using abrasives

Abrasive workers must be able to select the correct abrasive for the job at hand. They must consider the type of material being worked on, the desired finish, and the budget. They must also be able to properly use abrasives to achieve the desired results.

3. Inspecting and maintaining equipment

Abrasive workers must be able to inspect and maintain abrasive equipment to ensure that it is in good working condition. They must be able to identify potential problems and take corrective action. They must also be able to perform basic maintenance tasks, such as cleaning and lubricating equipment.

4. Following safety procedures

Abrasive workers must be aware of and follow all safety procedures. They must wear appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators. They must also be aware of the potential hazards of abrasive equipment and take steps to avoid them.

Interview Tips

Preparing for an interview for an abrasive worker position can be daunting, but with the right tips, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience they are looking for in a candidate.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, regardless of the position you are applying for. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely during your interview.

3. Dress appropriately

First impressions matter, so it is important to dress appropriately for your interview. For an abrasive worker position, you should wear clean, comfortable clothes that are appropriate for a manufacturing environment. You should also make sure that your clothes are free of any loose threads or jewelry that could get caught in equipment.

4. Be prepared to talk about your experience

The interviewer will likely want to know about your experience working with abrasive equipment. Be prepared to talk about your skills and experience in detail, and be sure to highlight any specific projects or accomplishments that are relevant to the position you are applying for.

5. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. Be sure to convey your passion for working with abrasive equipment and your commitment to safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Abrasive Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!