Are you gearing up for a career in Vertical Boring Mill Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vertical Boring Mill Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

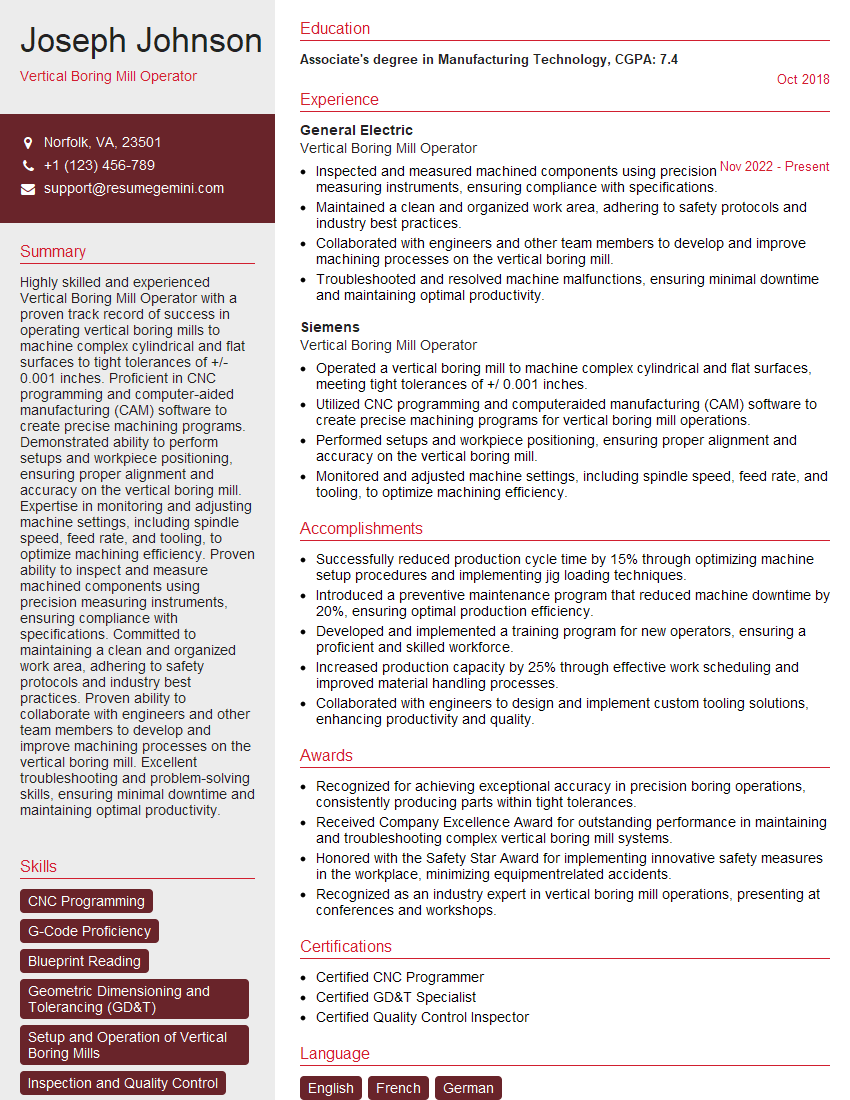

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vertical Boring Mill Operator

1. Describe the process of setting up a vertical boring mill for a new job.

- Review the blueprint and work order to understand the specifications of the job.

- Mount the workpiece onto the table and secure it with clamps and fixtures.

- Set the spindle speed, feed rate, and depth of cut according to the material and the desired finish.

- Install the appropriate tooling, such as boring bars, drills, and reamers.

- Fine-tune the alignments and offsets of the workpiece and tooling using a dial indicator or other precision measuring devices.

2. What are the different types of vertical boring mills and their applications?

Turret-type Vertical Boring Mills

- Multiple turrets with multiple tools

- Used for complex parts requiring multiple operations

Floor-type Vertical Boring Mills

- Large table size and heavy-duty construction

- Used for large workpieces, such as oil drilling platforms

Portable Vertical Boring Mills

- Smaller and more compact

- Used for on-site or in-field operations

3. How do you inspect and maintain a vertical boring mill?

- Regular cleaning and lubrication of all components

- Inspection of spindle bearings for wear or damage

- Check the condition of belts and chains

- Test the accuracy of the controls and safety features

- Monitor the hydraulic system for leaks or pressure issues

4. What are the safety precautions to observe when operating a vertical boring mill?

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and earplugs.

- Keep the work area clean and free of debris.

- Ensure that the workpiece is securely clamped and the tooling is properly installed.

- Follow established procedures for machine operation and maintenance.

- Always remain alert and attentive while operating the machine.

5. Describe the different types of cutting tools used on a vertical boring mill and their applications.

- Boring bars: Used for enlarging or finishing holes.

- Drills: Used for creating new holes.

- Reaming tools: Used for improving the accuracy and surface finish of holes.

- Facing tools: Used for creating flat surfaces.

- Contouring tools: Used for creating complex shapes.

6. How do you troubleshoot common problems that may occur while operating a vertical boring mill?

- Excessive vibration: Check for loose components, unbalanced workpiece, or worn bearings.

- Poor surface finish: Inspect the cutting tool for damage, adjust feed rate or spindle speed.

- Inaccurate dimensions: Verify workpiece alignment, check the accuracy of the measuring tools, or recalibrate the machine.

- Hydraulic leaks: Identify the source of the leak, tighten fittings, or replace seals.

- Electrical issues: Check for loose connections, faulty wiring, or damaged components.

7. What are the key factors to consider when selecting the correct cutting parameters for a boring operation?

- Material of the workpiece

- Diameter and depth of the hole

- Desired surface finish

- Type of cutting tool being used

- Capabilities of the machine

8. How do you calculate the feed rate and spindle speed for a boring operation?

Feed rate (FR) = Cutting speed (CS) / Number of teeth (N)

Spindle speed (N) = 1000 * Cutting speed (CS) / Diameter of cutting tool (D)

Where:

- Cutting speed (CS) is in meters/minute (m/min)

- Number of teeth (N) is the number of teeth on the cutting tool

- Diameter of cutting tool (D) is in millimeters (mm)

9. What are the advantages of using a vertical boring mill over other types of machine tools?

- High accuracy and precision

- Ability to handle large and heavy workpieces

- Versatile for a wide range of machining operations

- Automated features can increase productivity

- Improved safety with enclosed work area

10. What software is typically used for programming and controlling a vertical boring mill?

- Computer-aided manufacturing (CAM) software

- G-code or ISO code programming

- Human-machine interface (HMI) or control panel interface

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vertical Boring Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vertical Boring Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vertical Boring Mill Operator is responsible for operating and maintaining a vertical boring mill, a machine that bores holes and shapes metal parts. The operator ensures that the machine is set up correctly, that the workpiece is properly secured, and that the machine is operated safely.

1. Set up and operate the vertical boring mill

The operator sets up the vertical boring mill by installing the appropriate tooling and fixtures. They then load the workpiece into the machine and secure it in place. The operator then enters the machining program into the machine’s computer and starts the machining process.

2. Monitor the machining process

The operator monitors the machining process to ensure that the workpiece is being machined correctly. They watch for any signs of problems, such as chatter or excessive tool wear. If a problem occurs, the operator stops the machine and corrects the problem before continuing.

3. Measure and inspect the workpiece

The operator measures and inspects the workpiece to ensure that it meets the required specifications. They use a variety of measuring tools, such as calipers and micrometers, to check the dimensions of the workpiece. They also inspect the workpiece for any defects, such as cracks or burrs.

4. Maintain the vertical boring mill

The operator maintains the vertical boring mill by performing regular maintenance tasks, such as cleaning and lubricating the machine. They also inspect the machine for any signs of wear or damage. If a problem is found, the operator reports it to their supervisor.

Interview Tips

Preparing for an interview can be daunting but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. You can find information about the company on their website, social media, and Glassdoor.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills. Be prepared to talk about your work history, your education, and any relevant skills that you have. You can also mention any awards or recognition that you have received.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to show your excitement for the opportunity and your willingness to learn and grow.

5. Ask questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Vertical Boring Mill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.