Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Band Reamer Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Band Reamer Machine Operator so you can tailor your answers to impress potential employers.

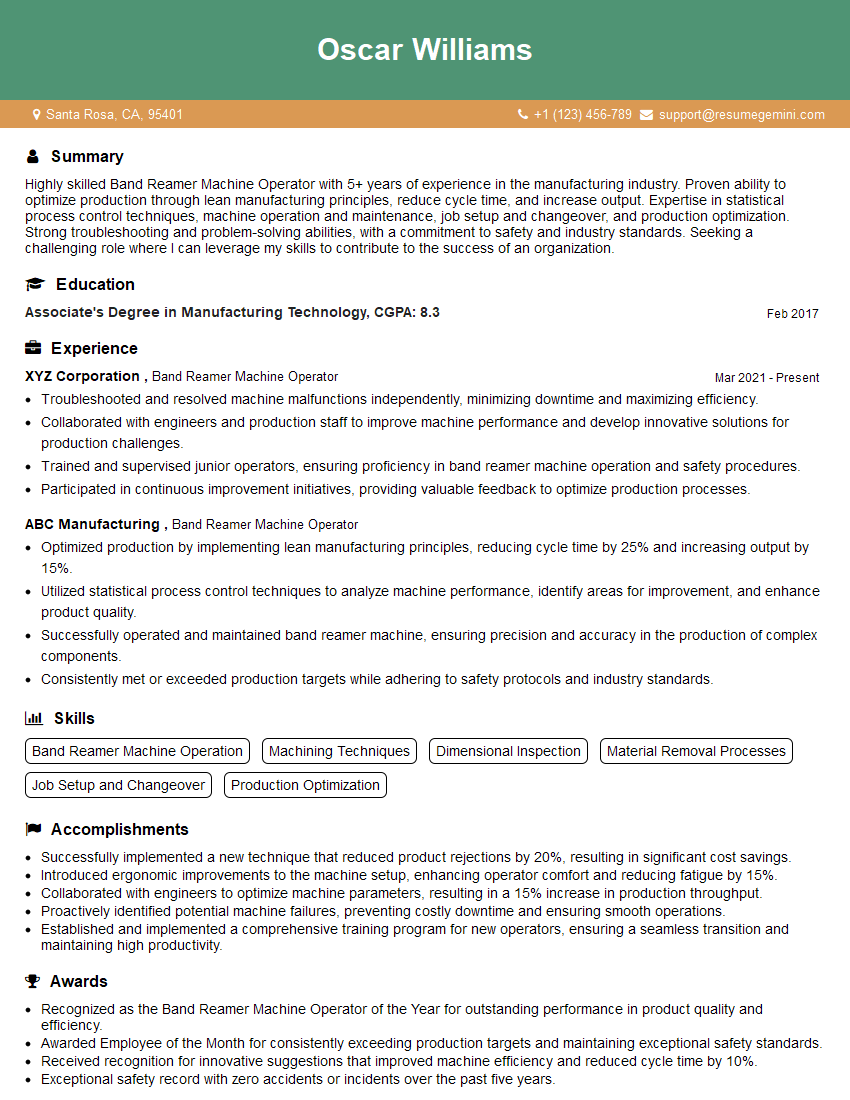

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Band Reamer Machine Operator

1. Explain the process of setting up a Band Reamer Machine?

Setting up a Band Reamer Machine involves the following steps:

- Selecting the appropriate band reamer for the desired hole size and material.

- Inspecting the band reamer for any damage or wear.

- Mounting the band reamer onto the machine spindle.

- Adjusting the cutting speed and feed rate based on the material being reamed.

- Setting the depth of cut and ensuring that the workpiece is securely clamped.

- Aligning the band reamer with the workpiece center.

2. Describe the different types of Band Reamers and their applications?

General Purpose Band Reamers:

- Suitable for a wide range of materials, including steel, aluminum, and plastics.

- Used for reaming holes to precise diameters and surface finishes.

Tungsten Carbide Band Reamers:

- Designed for reaming hard materials, such as hardened steel and exotic alloys.

- Offer increased wear resistance and longer tool life.

Adjustable Band Reamers:

- Allow for adjustments in the hole diameter by changing the position of the cutting inserts.

- Versatile for use in various hole sizes.

3. How do you identify and troubleshoot common Band Reamer Machine problems?

Common problems and troubleshooting steps:

- Chattering: Check for dull or damaged reamer, misalignment, or excessive feed rate.

- Oversized Holes: Adjust the cutting speed or feed rate, or use a smaller band reamer.

- Undersized Holes: Check for worn reamer, insufficient cutting speed or feed rate, or workpiece deflection.

- Poor Surface Finish: Inspect for worn reamer, excessive feed rate, or vibration in the machine.

4. What safety precautions should be taken when operating a Band Reamer Machine?

Safety precautions include:

- Wearing appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspecting the machine and reamer before each use.

- Ensuring that the workpiece is securely clamped.

- Avoiding contact with the rotating reamer.

- Following proper lockout/tagout procedures before performing maintenance or adjustments.

5. How do you maintain and calibrate a Band Reamer Machine for optimal performance?

Maintenance and calibration involve:

- Regular cleaning and lubrication of the machine.

- Inspecting and replacing worn or damaged parts.

- Calibrating the machine’s spindle speed and feed rate.

- Monitoring and adjusting the cutting fluid system.

6. Describe the different types of workholding devices used with Band Reamer Machines?

Collets:

- Use precision collets to hold round workpieces.

- Offer quick and easy workpiece changes.

Chucks:

- Used for holding workpieces with irregular shapes or large diameters.

- Provide greater gripping force.

Vises:

- Suitable for holding large or heavy workpieces.

- Offer secure clamping and precise alignment.

7. Explain the factors that affect the quality of the reamed hole?

Hole quality is influenced by:

- Band Reamer Condition: Sharp and undamaged reamer ensures better surface finish and accuracy.

- Cutting Parameters: Optimal speed and feed rates minimize chatter and ensure dimensional accuracy.

- Workpiece Material: Harder materials require slower speeds and higher feed rates.

- Machine Condition: A well-maintained machine with minimal vibration contributes to better hole quality.

8. Describe the process of rough and finish reaming?

Rough Reaming:

- Initial reaming pass to remove the majority of the material.

- Uses larger band reamer to quickly create the desired hole size.

Finish Reaming:

- Final reaming pass to achieve precise dimensions and surface finish.

- Uses smaller band reamer with tighter tolerances.

9. What is the role of cutting fluid in Band Reaming operations?

Cutting fluid serves multiple purposes:

- Cooling: Reduces heat generated during reaming, preventing tool and workpiece damage.

- Lubrication: Minimizes friction between the reamer and workpiece, extending tool life.

- Chip Removal: Flushes away metal chips, preventing them from accumulating and affecting hole quality.

10. Explain the importance of proper chip management in Band Reamer Machine operations?

Chip management is crucial for:

- Tool Life: Excessive chip accumulation can cause premature tool wear and breakage.

- Surface Finish: Trapped chips can scratch the reamed surface, affecting the workpiece quality.

- Safety: Cleared chips prevent buildup in the machine, reducing the risk of accidents.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Band Reamer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Band Reamer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Band Reamer Machine Operators play a crucial role in manufacturing processes by operating specialized machines with high precision. Their key responsibilities include:

1. Machine Operation

Skilled operation of band reamer machines to achieve precise dimensional tolerances and surface finishes.

2. Material Handling

Efficient handling of raw materials and finished products, ensuring proper loading, unloading, and storage.

3. Measurement and Inspection

Performing quality control checks by measuring and inspecting parts for accuracy, dimensional conformance, and surface finish.

4. Equipment Maintenance

Regular maintenance of band reamer machines, including cleaning, lubrication, and minor repairs to ensure optimal performance.

5. Safety and Compliance

Adhering to safety guidelines and protocols, maintaining a clean and organized work area, and using personal protective equipment.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and impress potential employers. Here are some tips to help you ace your interview:

1. Research the Company and Role

Thoroughly research the company’s values, mission, and industry reputation. Understand the specific responsibilities and requirements of the Band Reamer Machine Operator role.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating band reamer machines, handling materials, and performing quality control checks. Quantify your accomplishments whenever possible to demonstrate your impact.

3. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Tailor your responses to highlight your relevant skills and experiences.

4. Ask Thoughtful Questions

Show your interest and engagement by asking thoughtful questions about the company, the role, or the industry. This demonstrates your curiosity and genuine desire to learn more.

5. Be Professional and Enthusiastic

Arrive on time, dress appropriately, and maintain a positive and professional demeanor. Show enthusiasm for the role and demonstrate your eagerness to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Band Reamer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!