Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bearing Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

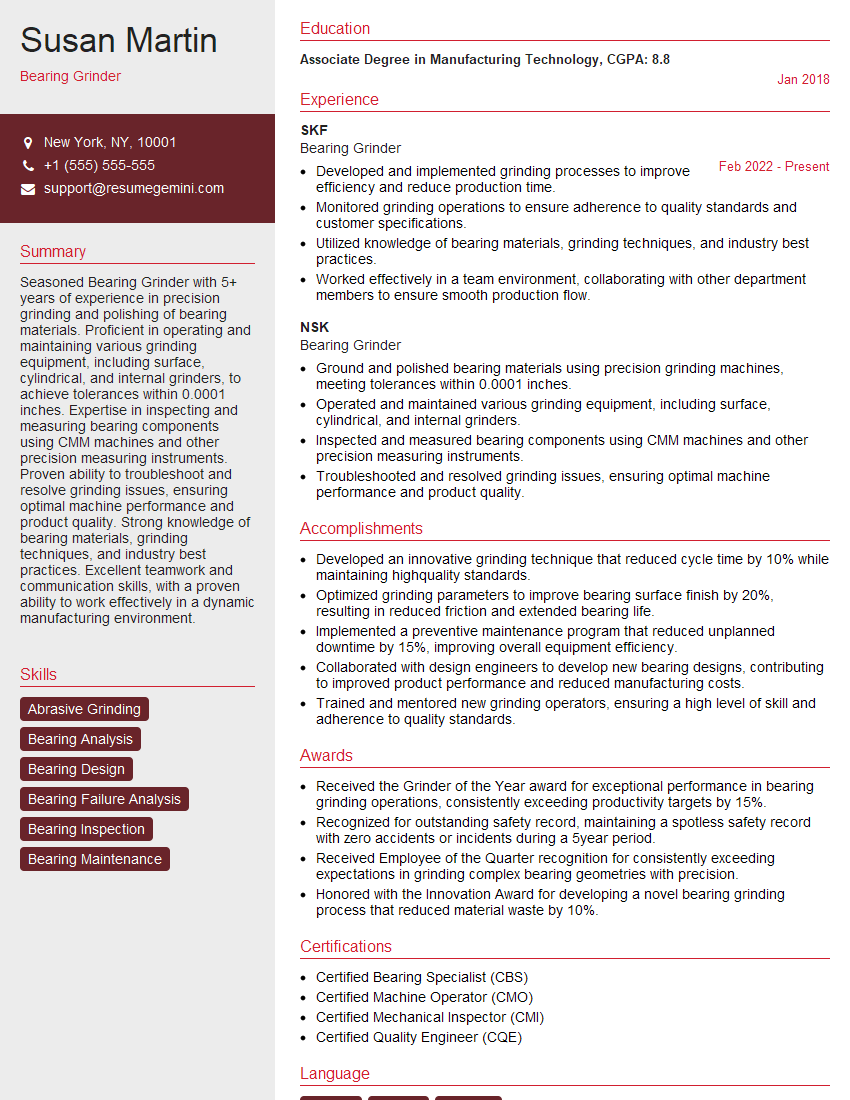

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bearing Grinder

1. How do you determine the correct grinding wheel for a particular bearing?

To determine the correct grinding wheel for a particular bearing, I consider factors such as:

- Bearing material (e.g., steel, ceramic)

- Bearing size and shape

- Desired surface finish

- Required accuracy and precision

- Type of grinding machine

2. Describe the steps involved in setting up a bearing grinding machine.

Machine Preparation

- Clean and inspect the machine

- Install the correct grinding wheel

- Calibrate the machine

Bearing Setup

- Mount the bearing on the fixture

- Set the appropriate grinding parameters (speed, feed, depth of cut)

- Rough grind the bearing

3. How do you monitor the grinding process to ensure quality control?

To ensure quality control during the grinding process, I employ various techniques, including:

- Visual inspection of the grinding wheel and bearing surface

- Measuring the bearing dimensions with micrometers or calipers

- Using gauges to check the surface finish

- Monitoring machine parameters (e.g., speed, temperature)

4. What are common problems encountered during bearing grinding and how do you troubleshoot them?

Common problems during bearing grinding include:

- Chattering: Adjust machine parameters or use a different grinding wheel

- Burning: Reduce grinding speed or depth of cut

- Excessive noise: Check machine alignment or replace the grinding wheel

- Improper surface finish: Adjust grinding parameters or use a different type of grinding wheel

5. What are the advantages and disadvantages of using CNC grinding machines for bearing manufacturing?

Advantages:

- Increased accuracy and precision

- Reduced setup times

- Automated process control

Disadvantages:

- Higher capital investment

- Need for skilled operators

- Limited flexibility in manufacturing different types of bearings

6. How do you maintain and calibrate bearing grinding machines to ensure optimal performance?

Regular maintenance and calibration are crucial to ensure optimal performance of bearing grinding machines. I follow a comprehensive maintenance schedule that includes:

- Cleaning and lubricating machine components

- Inspecting and replacing worn or damaged parts

- Calibrating machine settings according to manufacturer’s specifications

7. What experience do you have with grinding different types of bearings, such as ball bearings or roller bearings?

I have extensive experience in grinding various types of bearings, including:

- Ball bearings (deep groove, angular contact, thrust)

- Roller bearings (cylindrical, tapered, spherical)

- Needle bearings

- Specialty bearings (e.g., thrust ball bearings, magnetic bearings)

8. How do you stay updated with the latest advancements in bearing grinding technology?

To stay updated with the latest advancements in bearing grinding technology, I:

- Attend industry conferences and exhibitions

- Read technical journals and articles

- Network with colleagues and experts in the field

- Participate in training and development programs offered by equipment manufacturers

9. What safety precautions do you take when operating bearing grinding machines?

I prioritize safety when operating bearing grinding machines by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE)

- Inspecting the machine before use

- Following proper operating procedures

- Being aware of the machine’s potential hazards

- Maintaining a clean and organized work area

10. How do you work effectively with other members of a production team in a bearing manufacturing facility?

Effective teamwork is crucial in a production environment. I excel in working collaboratively by:

- Communicating clearly and effectively

- Sharing knowledge and expertise

- Supporting colleagues in meeting production goals

- Participating in problem-solving and process improvement initiatives

- Maintaining a positive and professional attitude

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bearing Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bearing Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bearing Grinders are responsible for operating and maintaining grinding machines to produce precision-ground bearings using an array of equipment. Their primary function is to grind and finish the surfaces of bearings to meet specific dimensional and quality requirements. They may work with various types of bearings, such as ball bearings, roller bearings, tapered bearings, and others, and ensure their proper functioning.The key responsibilities of a Bearing Grinder typically include:

1. Machine Operation

Operate and maintain grinding machines to grind and finish bearing surfaces to precise specifications.

- Set up and adjust grinding machines according to specifications.

- Load and unload bearings into and from machines.

- Monitor grinding operations and make adjustments as needed.

2. Quality Control

Inspect finished bearings to ensure they meet quality standards.

- Use precision measuring instruments to verify dimensions, tolerances, and surface finish.

- Identify and correct defects or non-conformances.

3. Maintenance

Perform routine maintenance and repairs on grinding machines and related equipment.

- Clean and lubricate machines and components.

- Replace worn or damaged parts.

- Troubleshoot and resolve mechanical issues.

4. Process Improvement

Continuously seek ways to improve grinding processes and efficiency.

- Identify areas for optimization and implement improvements.

- Stay updated on new technologies and techniques.

Interview Tips

To ace an interview for a Bearing Grinder position, it is essential to prepare thoroughly. Here are some tips and hacks to help you succeed:

1. Research the Company and Position

Before the interview, take the time to learn about the company and the specific role you are applying for. This will demonstrate your genuine interest and enthusiasm for the opportunity.

- Visit the company’s website to gather information about their products or services, industry, and culture.

- Review the job description carefully to understand the essential responsibilities, skills, and qualifications required.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your responses. This will help you articulate your experiences and qualifications effectively, and it will also boost your confidence.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples from your work experience.

- Focus on highlighting your relevant skills and accomplishments that align with the job requirements.

3. Demonstrate Your Technical Knowledge

As a Bearing Grinder, employers will expect you to possess a strong understanding of grinding machines and processes. Be prepared to discuss your experience with different types of grinding equipment and your knowledge of quality control techniques.

- Provide examples of projects or tasks where you successfully operated grinding machines and achieved desired results.

- Explain your understanding of bearing manufacturing processes and how grinding contributes to their precision and performance.

4. Emphasize Your Problem-Solving and Analytical Skills

Bearing Grinders often encounter technical challenges and must be able to solve problems effectively. Highlight your analytical skills and ability to identify and resolve issues with grinding machines or bearing components.

- Share instances where you diagnosed and repaired equipment malfunctions or identified quality issues and implemented corrective actions.

- Explain your approach to continuous improvement and how you have applied it in your previous role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bearing Grinder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.