Are you gearing up for an interview for a Barrel Polisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Barrel Polisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

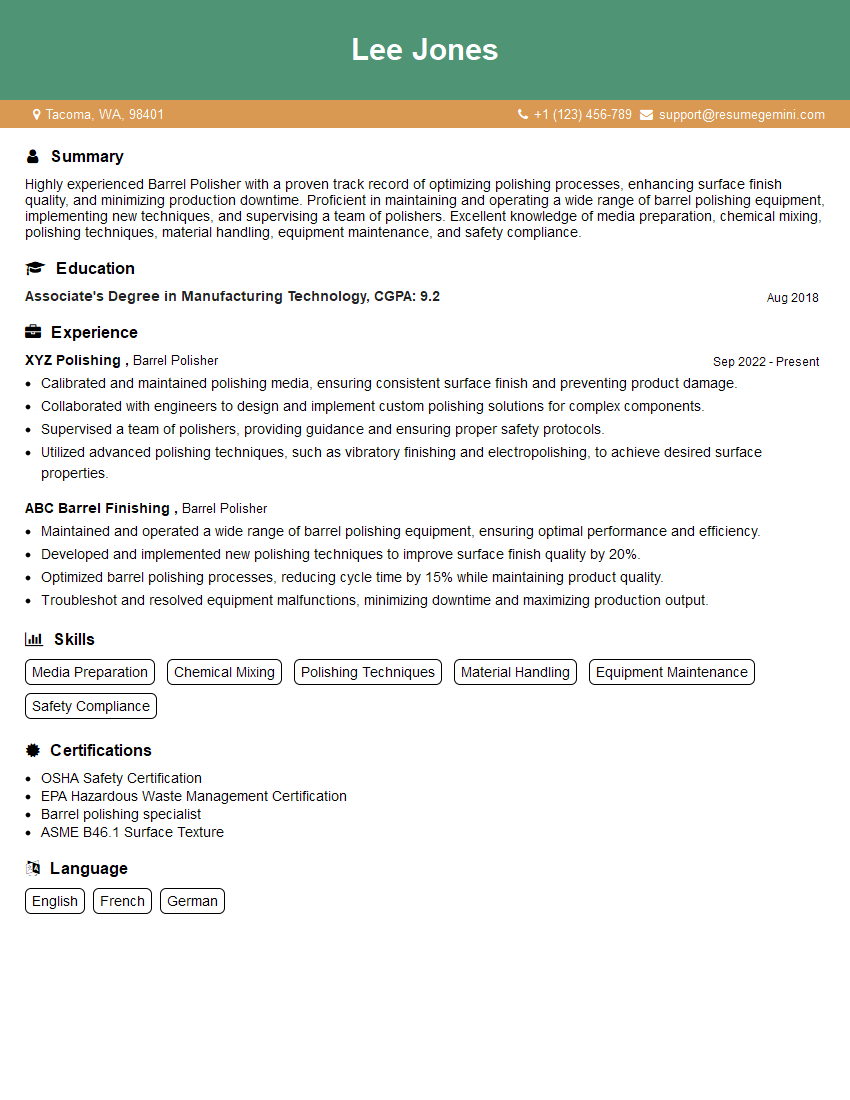

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Polisher

1. Explain the different types of polishing compounds used in barrel polishing?

There are various types of polishing compounds used in barrel polishing, each with specific characteristics and applications:

- Abrasive Compounds: These compounds contain abrasive particles, such as aluminum oxide or silicon carbide, and are used for removing material and smoothing surfaces.

- Pre-Polishing Compounds: These compounds are used after abrasive compounds to further refine the surface and remove fine scratches.

- Polishing Compounds: These compounds are used for final polishing to achieve a high level of surface smoothness and luster.

- Burnishing Compounds: These compounds are used to create a mirror-like finish by mechanically burnishing the surface.

2. Describe the factors that affect the barrel polishing process?

The barrel polishing process is influenced by several factors, including:

- Barrel Type: The type of barrel used, such as horizontal or vibratory, affects the agitation and impact of the media on the parts.

- Media Type and Quantity: The type and quantity of media, such as ceramic or plastic beads, determine the abrasive action and surface finish.

- Polishing Compound: The type and concentration of polishing compound used affect the material removal rate and surface smoothness.

- Barrel Speed: The speed at which the barrel rotates or vibrates influences the intensity of the polishing process.

- Processing Time: The duration of the polishing cycle determines the level of surface refinement achieved.

3. How do you troubleshoot common problems encountered in barrel polishing?

Common problems in barrel polishing and their troubleshooting steps include:

- Insufficient Polishing: Check media size, compound type and concentration, barrel speed, and processing time.

- Excessive Polishing: Reduce barrel speed, media quantity, or processing time to minimize material removal.

- Unwanted Surface Damage: Ensure proper media size, avoid overloading the barrel, and use a suitable polishing compound.

- Media Breakage: Select durable media that can withstand the impact and friction generated in the barrel.

- Compound Contamination: Clean the barrel regularly, use compatible compounds, and follow manufacturer’s guidelines.

4. What safety precautions are essential in barrel polishing?

Safety precautions for barrel polishing include:

- Wear appropriate protective equipment, including gloves, eye protection, and a respirator.

- Ensure the barrel is properly secured and grounded.

- Keep the work area clean and free from debris.

- Follow all manufacturer’s instructions for the equipment and materials used.

- Never open the barrel while it is in operation.

5. Describe the quality control measures you implement to ensure the quality of polished parts.

Quality control measures for barrel polished parts include:

- Visual Inspection: Inspect parts for surface finish, scratches, burrs, or other defects.

- Dimensional Measurement: Verify that parts meet specified dimensions using calipers or other measuring tools.

- Surface Roughness Measurement: Use a profilometer to measure the surface roughness and ensure it meets requirements.

- Hardness Testing: Perform hardness testing on parts to ensure proper surface hardening.

- Regular Equipment Calibration and Maintenance: Calibrate and maintain equipment regularly to ensure accurate measurements and consistent polishing results.

6. What are the key factors to consider when selecting media for barrel polishing?

When selecting media for barrel polishing, key factors to consider include:

- Abrasiveness: Media hardness and size determine the abrasiveness and material removal rate.

- Durability: Media should withstand impact and friction without excessive breakage.

- Shape: Media shape affects the surface finish and can influence polishing efficiency.

- Cost: Consider the cost per unit and longevity of the media.

- Compatibility: Ensure the media is compatible with the polishing compound and workpiece materials.

7. How do you determine the optimal polishing time for a given workpiece?

The optimal polishing time is determined based on factors such as:

- Material Hardness: Harder materials require longer polishing times.

- Surface Finish Requirements: A finer surface finish requires longer polishing.

- Barrel Capacity and Speed: The size and speed of the barrel affect polishing efficiency.

- Media Type and Quantity: Different media and quantities influence the abrasiveness and impact.

- Polishing Compound: Compound concentration and particle size affect the material removal rate.

8. What are the advantages of using automated barrel polishing systems?

Automated barrel polishing systems offer several advantages, including:

- Increased Efficiency: Automation reduces manual labor and improves productivity.

- Consistent Quality: Automated systems ensure consistent polishing parameters, resulting in uniform finishes.

- Reduced Labor Costs: Automation eliminates the need for extensive manual labor.

- Improved Safety: Automated systems minimize operator exposure to hazardous materials and processes.

- Data Tracking: Automation allows for data collection and tracking, enabling process optimization.

9. How do you maintain the accuracy of the equipment used in barrel polishing?

Maintaining equipment accuracy in barrel polishing involves:

- Regular Calibration: Calibrating equipment, such as scales and measuring devices, ensures accurate readings and measurements.

- Preventive Maintenance: Regular maintenance, such as cleaning, lubrication, and filter replacements, prevents equipment malfunctions and ensures optimal performance.

- Equipment Monitoring: Monitoring equipment during operation allows for early detection of any issues or deviations from desired parameters.

- Documentation: Maintaining records of calibration and maintenance activities provides traceability and accountability.

10. How do you stay updated with the latest advancements in barrel polishing techniques?

To stay updated with advancements in barrel polishing, I engage in the following activities:

- Industry Publications and Conferences: Attending industry events and reading trade publications provides insights into new technologies and best practices.

- Manufacturer Training: Participating in training programs offered by equipment and material manufacturers allows for direct access to technical updates.

- Online Resources: Exploring online forums, technical articles, and webinars helps me stay informed about the latest developments.

- Networking with Experts: Connecting with experienced professionals in the field enables me to exchange knowledge and learn from their expertise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Polishers are responsible for operating and maintaining barrel polishing machines, which are used to polish and smooth metal parts. Their primary objective is to achieve desired surface finishes, ensuring the parts meet quality and dimensional specifications. Let’s delve into their essential tasks:

1. Machine Operation

To begin with, Barrel Polishers set up and operate polishing machines, ensuring their proper functioning throughout the process. They load the machines with workpieces, abrasives, and water-based solutions, selecting the appropriate settings based on the materials being processed and desired finishes.

2. Process Monitoring

Once the machines are in operation, Barrel Polishers monitor the process closely, checking the progress of the parts and making necessary adjustments. They ensure adequate tumbling action, monitor solution levels and temperatures, and adjust the speed of the machine as needed to achieve optimal results.

3. Quality Control

Maintaining the quality of the polished parts is paramount. Barrel Polishers inspect the workpieces throughout the process, assessing their surface finish and dimensions. They check for any imperfections, scratches, or other defects, ensuring that the parts meet the required quality standards.

4. Machine Maintenance

To prevent disruptions and ensure smooth operation, Barrel Polishers are responsible for basic maintenance of the polishing machines. They clean and lubricate the machines regularly, inspect for any wear or damage, and perform minor repairs when necessary.

Interview Tips

Preparing for a Barrel Polisher interview requires a combination of technical knowledge, attention to detail, and a commitment to quality. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before you step into the interview room, take the time to research the company and the specific role you are applying for. Understand the company’s products, services, and industry standing. Knowing the company’s culture and values will demonstrate your genuine interest and enthusiasm for the position.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining barrel polishing machines. Explain your expertise in selecting abrasives, water-based solutions, and machine settings to achieve desired surface finishes. Share any experience you have in troubleshooting machine issues and performing basic repairs.

3. Showcase Your Quality Control Mindset

Interviewers will be keen to know your approach to quality control. Describe your understanding of the importance of maintaining precise surface finishes and dimensional specifications. Explain how you inspect parts throughout the process and identify any defects or imperfections.

4. Demonstrate Your Attention to Detail

Barrel polishing requires meticulous attention to detail. Highlight your strong observational skills and ability to spot even the smallest irregularities in the workpieces. Explain how you pay close attention to the machine’s settings, process progress, and overall condition during operation.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s quality standards, the specific requirements of the position, and any opportunities for professional development within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Barrel Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!