Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cutter Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

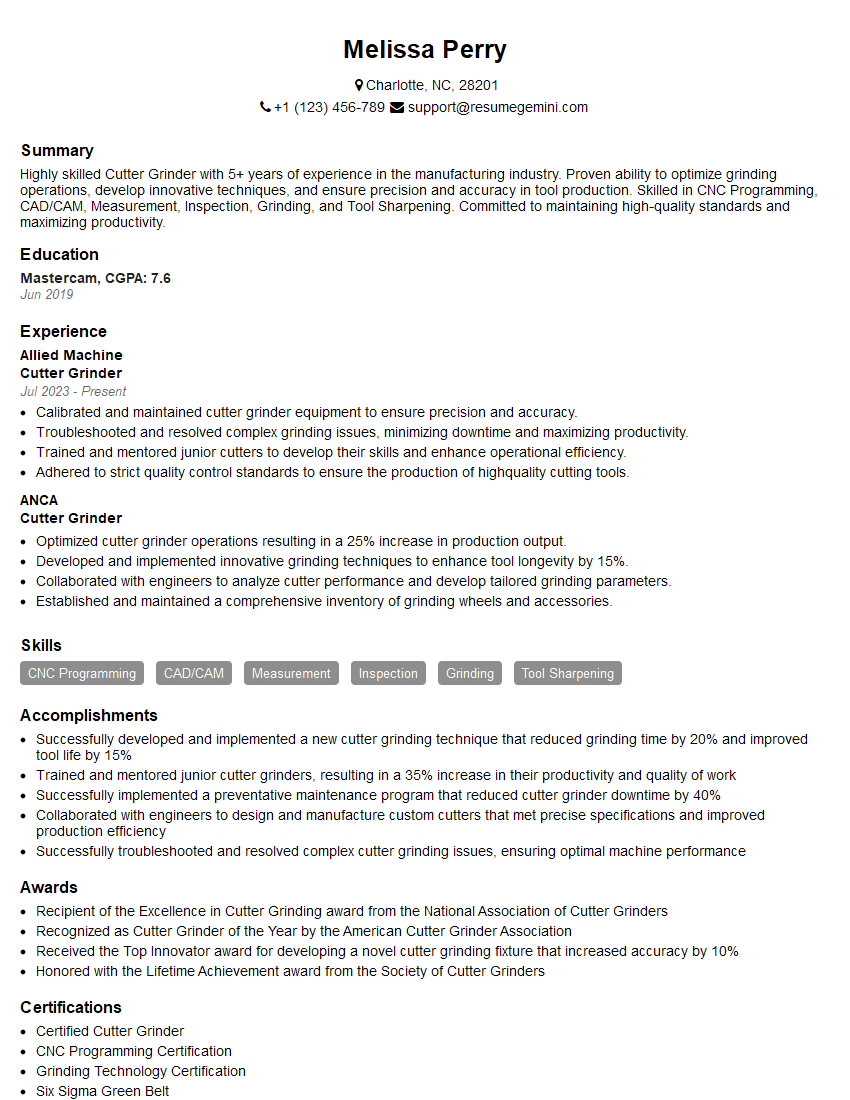

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter Grinder

1. Describe the different types of cutter grinders that you are familiar with and their applications?

Answer:

- Cylindrical Grinder: Used for grinding cylindrical surfaces on shafts, bearings, and other round workpieces.

- Surface Grinder: Used for grinding flat surfaces on plates, blocks, and other flat workpieces.

- Tool and Cutter Grinder: Used for grinding and sharpening cutting tools, such as milling cutters, drills, and taps.

- Internal Grinder: Used for grinding the inside diameter of holes, such as in cylinders and gears.

- Centerless Grinder: Used for grinding cylindrical workpieces without the need for centers.

2. What are the key components of a cutter grinder and their functions?

- Base: Provides a sturdy support for the machine and absorbs vibrations.

- Column: Supports the grinding head and allows it to move vertically.

- Grinding Head: Holds the grinding wheel and spindle, and controls its speed and direction of rotation.

- Table: Supports the workpiece and allows it to move horizontally or vertically.

- Coolant System: Provides coolant to the grinding zone to reduce friction and heat.

- Control System: Allows the operator to control the machine’s functions, such as speed, feed, and coolant flow.

3. Explain the process of setting up and operating a cutter grinder for a specific grinding operation?

- Select the appropriate grinding wheel: Consider the material of the workpiece, desired finish, and grinding conditions.

- Mount the grinding wheel: Securely fasten the wheel to the spindle and ensure it is balanced.

- Adjust the grinding head: Set the proper grinding angle, depth of cut, and wheel speed.

- Clamp the workpiece: Securely hold the workpiece on the table and adjust its position for the desired grinding operation.

- Start the grinding process: Start the grinding wheel and slowly engage it with the workpiece, monitoring the parameters to ensure proper results.

4. How do you ensure the accuracy and precision of the grinding operation?

- Properly set up the machine: Calibrate the machine and ensure all components are in good working order.

- Use high-quality grinding wheels: Select wheels that are suitable for the material and grinding conditions.

- Dress the grinding wheel regularly: Sharpen and shape the wheel to maintain its cutting efficiency.

- Monitor the grinding process: Observe the sparks and sound produced by the grinding operation to ensure proper cutting and avoid excessive wear.

5. Describe the safety precautions to be observed when operating a cutter grinder?

- Wear appropriate safety gear: Eye protection, gloves, and earplugs.

- Ensure the machine is properly grounded: Prevent electrical hazards.

- Keep the work area clean: Remove any debris or chips that could cause accidents.

- Never touch the rotating grinding wheel: Wait for it to come to a complete stop before handling.

- Follow the manufacturer’s instructions: Refer to the machine manual for specific safety guidelines.

6. What are the common problems that can occur during the grinding operation and how do you troubleshoot them?

- Excessive sparking: Adjust the grinding parameters, dress the wheel, or check for workpiece hardness.

- Chattering: Reduce the grinding speed, adjust the workpiece clamping, or check for wheel imbalance.

- Burn marks on the workpiece: Reduce the grinding pressure, increase the coolant flow, or use a coarser grinding wheel.

- Wheel glazing: Dress the wheel to remove the glazed surface and restore cutting efficiency.

- Excessive wear on the grinding wheel: Check the wheel selection, grinding parameters, and workpiece material.

7. Explain the importance of coolant in the grinding process and how do you maintain the coolant system?

Importance of Coolant:

- Reduces friction and heat.

- Removes chips and debris.

- Improves surface finish.

- Extends grinding wheel life.

Coolant Maintenance:

- Monitor coolant level and top up as needed.

- Filter the coolant to remove chips and debris.

- Check coolant concentration and adjust according to manufacturer’s recommendations.

- Clean the coolant reservoir and lines regularly.

8. How do you interpret the markings on a grinding wheel and what do they indicate?

Markings:

- Abrasive Type: A, C, etc.

- Grain Size: 24, 36, etc.

- Grade: Soft (A) to Hard (Z)

- Structure: Open (1) to Dense (10)

- Bond Type: Vitrified (V), Resin (R), etc.

- Diameter: Inches or millimeters

- Thickness: Inches or millimeters

Interpretation:

9. What is the difference between plunge grinding and traverse grinding?

- Plunge Grinding: The grinding wheel moves towards the workpiece axially, creating a cylindrical or conical surface.

- Traverse Grinding: The grinding wheel moves parallel to the workpiece surface, creating a flat or parallel surface.

10. Explain the role of a CNC (Computer Numerical Control) system in a cutter grinder and its benefits?

- Automation: CNC controls the machine’s movements based on a programmed code, reducing manual labor.

- Precision: CNC systems provide high accuracy and repeatability in the grinding process.

- Efficiency: CNC automation allows for faster and more efficient grinding operations.

- Complex Geometries: CNC systems can grind complex shapes and contours with ease.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutter Grinders are responsible for sharpening and repairing cutting tools used in various industries, ensuring optimal performance and efficiency. Their primary duties include:

1. Tool Grinding and Sharpening

Grind and sharpen a wide range of cutting tools, including milling cutters, drills, reamers, and end mills, using specialized grinding machines.

- Analyze tool condition and determine appropriate grinding techniques

- Select and install grinding wheels with the correct specifications

2. Tool Inspection and Measurement

Inspect and measure tools before and after grinding to ensure dimensional accuracy and surface finish meet specifications.

- Utilize precision measuring instruments, such as calipers, micrometers, and height gauges

- Identify and correct deviations from desired specifications

3. Machine Maintenance and Calibration

Maintain and calibrate grinding machines to ensure proper operation and accuracy.

- Lubricate and adjust machines as needed

- Calibrate grinding wheels and other components to meet industry standards

4. Tool Design and Modification

Design and modify cutting tools to meet specific requirements and improve performance.

- Understand principles of tool design and materials engineering

- Collaborate with engineers and machinists to develop custom solutions

Interview Tips

Preparing thoroughly for a Cutter Grinder interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Delve into the company’s profile, website, and recent news to understand their business operations and industry trends.

- Research the specific industry the company serves

- Identify their competitors and market position

2. Practice Your Skills and Knowledge

Review your technical skills and knowledge related to cutting tool grinding. Consider practicing on sample tools if possible.

- Demonstrate your proficiency in grinding techniques and tool inspection

- Prepare examples of your work and be ready to discuss your approach to problem-solving

3. Highlight Your Passion and Motivation

Express your interest in the field and explain why you are passionate about cutter grinding.

- Share your knowledge of industry best practices and innovative techniques

- Convey your willingness to learn and grow within the company

4. Prepare Questions for the Interviewers

Preparing thoughtful questions for the interviewers shows your engagement and interest in the opportunity.

- Ask about the company’s growth plans and industry outlook

- Inquire about opportunities for professional development and training

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutter Grinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.