Are you gearing up for a career in End Polisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for End Polisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For End Polisher

1. How would you ensure that the polished surface is free of any imperfections?

- Inspect the surface under bright light to identify any visible defects.

- Use a magnifying glass to examine the surface for microscopic imperfections.

- Run a clean, soft cloth over the surface to detect any raised or rough areas.

- Apply a solvent to the surface and wipe it away to remove any contaminants or residue.

- Perform a final visual inspection to confirm that the surface is blemish-free.

2. What techniques do you use to achieve a high-gloss finish?

a) Mechanical Buffing:

- Select the appropriate abrasive compound and buffing wheel for the material being polished.

- Apply the compound to the wheel and start buffing the surface in small, circular motions.

- постепенно increase the pressure and speed of the buffing motion until the desired gloss is achieved.

b) Chemical Polishing:

- Immerse the surface in a chemical solution that dissolves the surface layer.

- Control the etching process to remove the necessary amount of material.

- Rinse and neutralize the surface to stop the etching reaction.

3. How do you handle delicate or fragile materials during the polishing process?

- Use specialized equipment and techniques designed for delicate materials.

- Apply lighter pressure and slower speeds during the polishing process.

- Secure the material firmly to prevent it from moving or vibrating during polishing.

- Monitor the temperature of the surface to prevent overheating and damage.

- Use soft, non-abrasive cloths and materials to avoid scratching or abrading the surface.

4. What safety precautions should be taken when operating polishing equipment?

- Wear appropriate personal protective equipment, including eye protection, gloves, and a dust mask.

- Ensure that the equipment is properly grounded and maintained.

- Keep the work area well-ventilated to prevent the accumulation of dust or fumes.

- Never operate polishing equipment near flammable materials.

- Follow manufacturer’s instructions and safety guidelines for specific equipment.

5. How do you troubleshoot common polishing problems, such as surface hazing or pitting?

a) Surface Hazing:

- Check for the presence of contaminants, such as oil or grease, that can cause clouding.

- Use a degreasing agent to remove contaminants.

- Adjust the polishing compound and pressure to reduce the risk of heat buildup and hazing.

b) Surface Pitting:

- Inspect the polishing tool or wheel for damage that may cause pitting.

- Reduce the polishing pressure and speed.

- Use a finer abrasive compound to minimize surface scratching.

- Etch the surface to remove any imbedded particles.

6. What techniques do you use to polish different types of materials, such as metals, plastics, and ceramics?

-

Metals:

- Mechanical buffing with abrasive compounds and polishing wheels.

- Electrolytic polishing to remove surface imperfections and achieve a smooth finish. Plastics:

- Flame polishing to seal and smooth the surface.

- Chemical polishing with solvents or acids to dissolve surface imperfections. Ceramics:

- Mechanical polishing with diamond abrasives to achieve a high-gloss finish.

- Glazing or vitrification to fuse a protective layer on the ceramic surface.

7. How do you maintain and calibrate polishing equipment to ensure accurate and consistent results?

- Regularly clean and inspect equipment to identify any wear or damage.

- Calibrate polishing tools, such as buffing wheels and abrasive compounds, according to manufacturer’s specifications.

- Monitor the equipment’s performance and make necessary adjustments to maintain optimal operating conditions.

- Follow established maintenance schedules and procedures to extend the equipment’s lifespan and accuracy.

8. What quality control methods do you use to ensure that polished surfaces meet the required standards?

- Visual inspection to identify any visible defects or imperfections.

- Surface roughness measurements using profilometry or other instruments.

- Gloss measurements to assess the degree of surface reflection.

- Microscopic examination to verify the absence of contamination or surface damage.

- Regular audits and documentation to ensure ongoing compliance with quality standards.

9. How do you manage your time effectively when working on multiple polishing projects?

- Prioritize tasks based on deadlines and customer requirements.

- Plan and schedule polishing operations to optimize equipment usage and minimize downtime.

- Delegate tasks to team members and provide clear instructions to ensure efficiency.

- Use technology to streamline communication and track project progress.

- Continuously evaluate and adjust the workflow to identify areas for improvement.

10. How do you stay updated on the latest polishing techniques and industry best practices?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with equipment manufacturers and suppliers.

- Network with other professionals in the field.

- Participate in online forums and discussion groups.

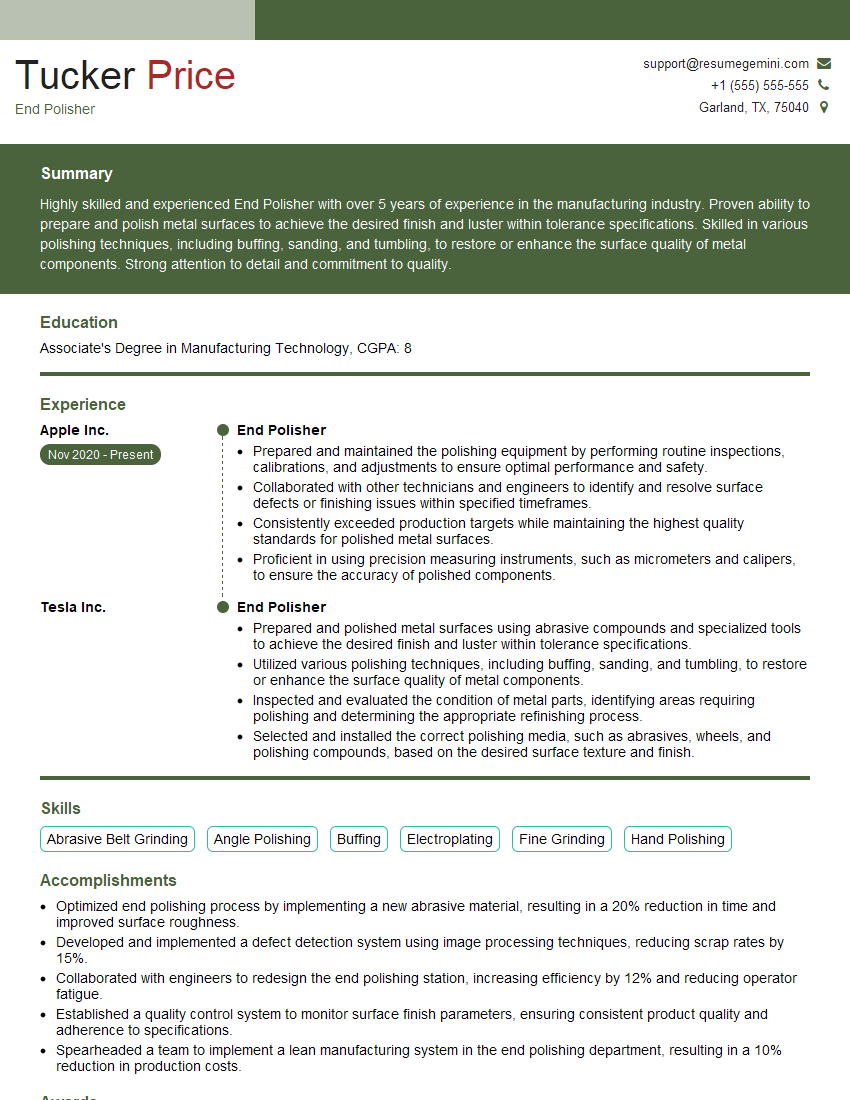

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for End Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the End Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An End Polisher is responsible for polishing the final product to achieve the desired finish.

1. Surface Preparation

Inspect the surface of the product to ensure it is free of defects.

- Remove any dirt, dust, or debris.

- Apply a primer or other preparatory materials as required.

2. Polishing

Use a variety of polishing tools and techniques to achieve the desired finish.

- Select the correct polishing compound for the material.

- Apply the compound and buff the surface using a polishing wheel or machine.

3. Final Inspection

Inspect the finished product to ensure it meets the required standards.

- Check for any defects or imperfections.

- Make any necessary adjustments or repairs.

4. Quality Control

Maintain and monitor the quality of the polishing process.

- Document the polishing process and its results.

- Identify and address any quality issues that may arise.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an End Polisher position:

1. Research the Company

Take the time to learn about the company’s history, values, and products. This will help you understand the company’s culture and what they are looking for in a new employee.

- Visit the company’s website and social media pages.

- Read any news articles or press releases about the company.

2. Practice Your Answers

Take some time to think about the questions you are likely to be asked in an interview. Practice answering these questions out loud to improve your delivery and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your skills and experience that are relevant to the job.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also arrive on time for your interview.

- Consider wearing a suit or business casual attire.

- Make sure your clothes are clean and free of wrinkles.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the job and the company. Be sure to convey your interest in the position and the company during your interview.

- Smile and make eye contact with the interviewer.

- Use positive body language and speak clearly and confidently.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a End Polisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for End Polisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.